GMW2M-ST-S

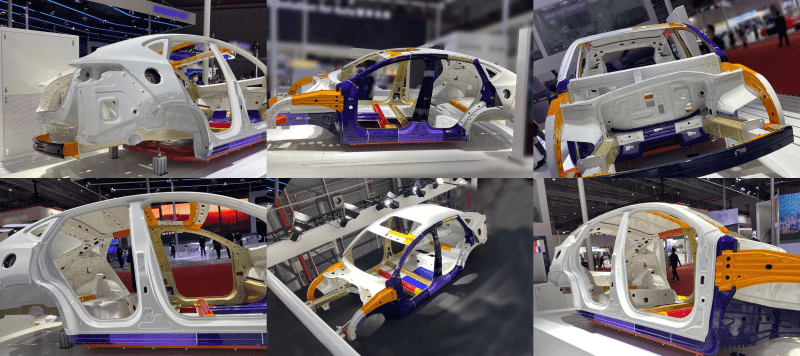

So-Lucky Steel is committed to providing customers with a whole supply chain solution for the Automobile industry, GMW2M-ST-S can provide you the GMW series product to support your company or factory. You can also get more die test or mass production materials, various processing schemes, special-shaped parts, laser welding, etc. for supporting stamping parts, sheet metal parts manufacturers, and household appliances manufacturers of major automobile main engine factories.

The following of GMW2M-ST-S car model is as below:

Automobile Steel GMW2M-ST-S Grades

There are 174 kinds of GMW2M-ST-S products model in total as below.

| Model Number | Model Number |

| GMW2M-ST-S-CR1-HD40G40G-U | GMW3032M-ST-S-HR550LA-HD50G50G-U |

| GMW2M-ST-S-CR2-HD40G40G-U | GMW3399M-ST-S-CR450T/250Y-DP-HD50G50G-U |

| GMW2M-ST-S-CR3-HD40G40G-U | GMW3399M-ST-S-CR780T/420Y-DP-HD50G50G-U |

| GMW2M-ST-S-CR4-HD40G40G-U | GMW3399M-ST-S-CR590T/280Y-DP-HD50G50G-U |

| GMW2M-ST-S-CR5-HD40G40G-U | GMW3399M-ST-S-CR590T/340Y-DP-HD50G50G-U |

| GMW2M-ST-S-CR1-HD90G90G-U | GMW3399M-ST-S-CR780T/420Y-DP-HD50G50G-U |

| GMW2M-ST-S-CR2-HD90G90G-U | GMW3399M-ST-S-CR780T/500Y-DP-HD50G50G-U |

| GMW2M-ST-S-CR3-HD90G90G-U | GMW3399M-ST-S-CR980T/550Y-DP-HD50G50G-U |

| GMW2M-ST-S-CR4-HD90G90G-U | GMW3399M-ST-S-CR590T/380Y-TR-HD50G50G-U |

| GMW2M-ST-S-CR5-HD90G90G-U | GMW3399M-ST-S-CR690T/410Y-TR-HD50G50G-U |

| GMW2M-ST-S-CR1-HD60G60G-U | GMW3399M-ST-S-CR780T/440Y-TR-HD50G50G-U |

| GMW2M-ST-S-CR2-HD60G60G-U | GMW3399M-ST-S-CR980T/500Y- MP-LCE HD50G50G |

| GMW2M-ST-S-CR3-HD60G60G-U | GMW3399M-ST-S-CR450T/250Y-DP-HD60G60G-U |

| GMW2M-ST-S-CR4-HD60G60G-U | GMW3399M-ST-S-CR780T/420Y-DP-HD60G60G-U |

| GMW2M-ST-S-CR5-HD60G60G-U | GMW3399M-ST-S-CR590T/280Y-DP-HD60G60G-U |

| GMW2M-ST-S-CR1-HD70G70G-U | GMW3399M-ST-S-CR590T/340Y-DP-HD60G60G-U |

| GMW2M-ST-S-CR2-HD70G70G-U | GMW3399M-ST-S-CR780T/420Y-DP-HD60G60G-U |

| GMW2M-ST-S-CR3-HD70G70G-U | GMW3399M-ST-S-CR780T/500Y-DP-HD60G60G-U |

| GMW2M-ST-S-CR4-HD70G70G-U | GMW3399M-ST-S-CR980T/550Y-DP-HD60G60G-U |

| GMW2M-ST-S-CR5-HD70G70G-U | GMW3399M-ST-S-CR590T/380Y-TR-HD60G60G-U |

| GMW3032M-ST-S-270LA-HD60G60G-U | GMW3399M-ST-S-CR690T/410Y-TR-HD60G60G-U |

| GMW3032M-ST-S-CR180B2-HD60G60G-U | GMW3399M-ST-S-CR780T/440Y-TR-HD60G60G-U |

| GMW3032M-ST-S-210P-HD60G60G-U | GMW3399M-ST-S-CR980T/700Y- MP-LCE HD60G60G |

| GMW3032M-ST-S-CR180IF-HD60G60G-U | GMW3399M-ST-S-CR450T/250Y-DP-HD70G70G-U |

| cGMW3032M-ST-S-CR240IF-HD60G60G-U | GMW3399M-ST-S-CR780T/420Y-DP-HD70G70G-U |

| GMW3032M-ST-S-CR180B2-HD60G60G-U | GMW3399M-ST-S-CR590T/280Y-DP-HD70G70G-U |

| GMW3032M-ST-S-CR210B2-HD60G60G-U | GMW3399M-ST-S-CR590T/340Y-DP-HD70G70G-U |

| GMW3032M-ST-S-CR270B2-HD60G60G-U | GMW3399M-ST-S-CR780T/420Y-DP-HD70G70G-U |

| GMW3032M-ST-S-CR300B2-HD60G60G-U | GMW3399M-ST-S-CR780T/500Y-DP-HD70G70G-U |

| GMW3032M-ST-S-CR270LA-HD60G60G-U | GMW3399M-ST-S-CR980T/550Y-DP-HD70G70G-U |

| GMW3032M-ST-S-CR300LA-HD60G60G-U | GMW3399M-ST-S-CR590T/380Y-TR-HD70G70G-U |

| GMW3032M-ST-S-HR340LA-HD60G60G-U | GMW3399M-ST-S-CR690T/410Y-TR-HD70G70G-U |

| GMW3032M-ST-S-CR340LA-HD60G60G-U | GMW3399M-ST-S-CR780T/440Y-TR-HD70G70G-U |

| GMW3032M-ST-S-CR380LA-HD60G60G-U | GMW3399M-ST-S-CR980T/700Y- MP-LCE HD70G70G |

| GMW3032M-ST-S-CR420LA-HD60G60G-U | GMW3399M-ST-S-CR450T/250Y-DP |

| GMW3032M-ST-S-HR420LA-HD60G60G-U | GMW3399M-ST-S-CR490T/290Y-DP |

| GMW3032M-ST-S-HR550LA-HD60G60G-U | GMW3399M-ST-S-CR590T/280Y-DP |

| GMW3032M-ST-S-CR180IF-HD70G70G-U | GMW3399M-ST-S-CR590T/340Y-DP |

| GMW3032M-ST-S-CR210IF-HD70G70G-U | GMW3399M-ST-S-CR690T/550Y-DP |

| GMW3032M-ST-S-CR240IF-HD70G70G-U | GMW3399M-ST-S-CR780T/420Y-DP |

| GMW3032M-ST-S-CR180B2-HD70G70G-U | GMW3399M-ST-S-CR780T/500Y-DP |

| GMW3032M-ST-S-CR210B2-HD70G70G-U | GMW3399M-ST-S-CR980T/550Y-DP |

| GMW3032M-ST-S-CR270B2-HD70G70G-U | GMW3399M-ST-S-CR980T/700Y-DP |

| GMW3032M-ST-S-CR300B2-HD70G70G-U | GMW2M-ST-S CR1 UNCOATED |

| GMW3032M-ST-S-CR270LA-HD70G70G-U | GMW2M-ST-S CR2 UNCOATED |

| GMW3032M-ST-S-CR300LA-HD70G70G-U | GMW2M-ST-S CR3 UNCOATED |

| GMW3032M-ST-S-HR340LA-HD70G70G-U | GMW2M-ST-S CR4 UNCOATED |

| GMW3032M-ST-S-CR340LA-HD70G70G-U | GMW2M-ST-S CR5 UNCOATED |

| GMW3032M-ST-S-CR380LA-HD70G70G-U | GMW2M-ST-S CR1 UNCOATED |

| GMW3032M-ST-S-CR420LA-HD70G70G-U | GMW3032M-ST-S-CR180B2-UNCOATED-U |

| GMW3032M-ST-S-CR500LA-HD70G70G-U | GMW3032M-ST-S-210P-UNCOATED-U |

| GMW3032M-ST-S-CR550LA-HD70G70G-U | GMW3032M-ST-S-CR180IF-UNCOATED-U |

| GMW3032M-ST-S-CR650LA-HD70G70G-U | GMW3032M-ST-S-CR210IF-UNCOATED-U |

| GMW3032M-ST-S-HR420LA-HD70G70G-U | GMW3032M-ST-S-CR240IF-HUNCOATED-U |

| GMW3032M-ST-S-HR550LA-HD70G70G-U | GMW3032M-ST-S-CR180B2-UNCOATED-U |

| GMW3032M-ST-S-CR180P-HD70G70G-U | GMW3032M-ST-S-CR210B2-UNCOATED-U |

| GMW3032M-ST-S-CR240P-HD70G70G-U | GMW3032M-ST-S-CR250B2-UNCOATED-U |

| GMW3032M-ST-S-CR270P-HD70G70G-U | GMW3032M-ST-S-CR300B2-UNCOATED-U |

| GMW3032M-ST-S-CR180P-HD60G60G-U | GMW3032M-ST-S-CR250LA-UNCOATED-U |

| GMW3032M-ST-S-CR240P-HD60G60G-U | GMW3032M-ST-S-CR240LA-UNCOATED-U |

| GMW3032M-ST-S-CR270P-HD60G60G-U | GMW3032M-ST-S-CR300LA-UNCOATED-U |

| GMW2M-ST-S-CR1-HD50G50G-U | GMW3032M-ST-S-HR340LA-UNCOATED-U |

| GMW2M-ST-S-CR2-HD50G50G-U | GMW3032M-ST-S-CR340LA-UNCOATED-U |

| GMW2M-ST-S-CR3-HD50G50G-U | GMW3032M-ST-S-CR380LA-UNCOATED-U |

| GMW2M-ST-S-CR4-HD50G50G-U | GMW3032M-ST-S-CR420LA-UNCOATED-U |

| GMW2M-ST-S-CR5-HD50G50G-U | GMW3032M-ST-S-HR420LA-UNCOATED-U |

| GMW3032M-ST-S-250LA-HD50G50G-U | GMW3032M-ST-S-HR550LA-UNCOATED-U |

| GMW3032M-ST-S-CR180B2-HD50G50G-U | GMW3032M-ST-S-HR650LA-UNCOATED-U |

| GMW3032M-ST-S-210P-HD50G50G-U | GMW2M- ST-S CR1 GMW11M EG50G50GE |

| GMW3032M-ST-S-CR180IF-HD50G50G-U | GMW2M-ST-S CR2 GMW11M EG50G50GE |

| GMW3032M-ST-S-CR210IF-HD50G50G-U | GMW2M-ST- S CR3 GMW11M EG50G50GE |

| GMW3032M-ST-S-CR240IF-HD50G50G-U | GMW2M-ST-S CR4 GMW11M EG50G50GE |

| GMW3032M-ST-S-CR180B2-HD50G50G-U | GMW2M-ST- S CR5 GMW11M EG50G50GE |

| GMW3032M-ST-S-CR210B2-HD50G50G-U | GMW2M-ST-S CR1 GMW11M EG60G60GE |

| GMW3032M-ST-S-CR250B2-HD50G50G-U | GMW2M-ST- S CR2 GMW11M EG60G60GE |

| GMW3032M-ST-S-CR300B2-HD50G50G-U | GMW2M-ST-S CR3 GMW11M EG60G60GE |

| GMW3032M-ST-S-CR250LA-HD50G50G-U | GMW2M-ST- S CR4 GMW11M EG60G60GE |

| GMW3032M-ST-S-CR240LA-HD50G50G-U | GMW2M-ST-S CR5 GMW11M EG60G60GE |

| GMW3032M-ST-S-CR240LA-HD60G60G-U | GMW2M-ST-S CR1 EG50G50GE |

| GMW3032M-ST-S-CR240LA-HD70G70G-U | GMW2M-ST-S CR2 EG50G50GE |

| GMW3032M-ST-S-CR300LA-HD50G50G-U | GMW2M-ST-S CR3 EG50G50GE |

| GMW3032M-ST-S-HR340LA-HD50G50G-U | GMW2M-ST-S CR4 EG50G50GE |

| GMW3032M-ST-S-CR340LA-HD50G50G-U | GMW2M-ST- S CR5 EG50G50GE |

| GMW3032M-ST-S-CR380LA-HD50G50G-U | GMW2M-ST-S CR1 EG60G60GE |

| GMW3032M-ST-S-CR420LA-HD50G50G-U | GMW2M-ST- S CR2 EG60G60GE |

| GMW3032M-ST-S-HR420LA-HD50G50G-U | GMW2M-ST-S CR3 EG60G60GE |

| GMW2M-ST- S CR4 EG60G60GE | GMW2M-ST-S CR5 EG60G60GE |

GMW2M-ST-S Business Cooperation

If you are interested with our automotive steel coil or sheet/plate to GMW2M-ST-S, get more GMW2M-ST-S steel price and information here. we will answer you as soon as possible.

Steel for GMW3032M FAQS

What is GMW3032M steel?

GMW3032M steel refers to automotive steel that conforms to the global standard. All material settings are based on the global basic regulations, including the amount of metal, the type of steel product, the minimum yield strength and the standard of polishing type. The type of steel product is Cold-rolled CR products and hot-rolled HR products.

This steel grade is commonly used in structural applications in the automotive industry, such as chassis and body panels. GMW3032M has excellent mechanical properties, especially at high temperatures, making it ideal for use in high temperature environments. This steel grade also has good corrosion resistance and is easy to weld, making it a versatile choice for a variety of applications.

What are the chemical compositions of GMW3032M steel?

GMW3032M steel is a low carbon high strength steel commonly used in automotive applications. The chemical composition of GMW3032M steel includes:

– Carbon: 0.06-0.13%

– Manganese: 0.60-1.20%

– Silicon: 0.17-0.37%

– Phosphorus: ≦ 0.035%

– Sulfur: ≦ 0.040%

What are the physical properties of GMW3032M steel?

GMW3032M steel is a high strength low alloy steel specially designed for use in the automotive industry. The material has many physical properties that make it ideal for automotive manufacturing. First, GMW3032M steel is extremely strong and durable, meaning it can withstand the high temperatures and pressures involved in the car manufacturing process. Second, the material is highly resistant to corrosion, making it ideal for cars that may be exposed to harsh weather conditions. Finally, GMW3032M steel is also very weldable, meaning it can be easily joined together during fabrication.

What are the mechanical properties of GMW3032M steel?

GMW3032M is a high strength, low alloy steel with good formability, weldability and toughness. This material is commonly used in automotive and construction applications. The following are the mechanical properties of GMW3032M steel:

Yield Strength: 550 MPa (79,000 psi)

Tensile Strength: 760 MPa (110,000 psi)

Elongation: 18%

Reduction of area: 55%

Modulus of Elasticity: 190 GPa (28 x 106psi)

Shear Modulus: 75 GPa (11 x 106psi)

Brinell hardness: 269 HBW

What is the microstructure of GMW3032M steel?

Particle Size: By analysis, the particle size tested in accordance with ASTM E112 shall be continuous through the thickness. The particle size of the hot rolled substrate is No. 6 or smaller. The particle size of the cold-rolled matrix is No. 8 or smaller.

What are the welding requirements for GMW3032M steel?

GMW3032M steel has no special regulations for rolling welding of coils that are transferred from the production process of hot-rolled coils to cooling and cooling. Seam-welded coils that have been cold-rolled to allow drilling to inspect welded parts prior to stamping should be avoided as much as possible. Cold-rolled coils with exposed faces can be welded and punched for marking. Welding of non-exposed cold-rolled coils is not permitted unless specifically permitted by the local organization.

What are the thermal properties of GMW3032M steel?

GMW3032M steel is a low carbon high strength steel commonly used in automotive applications. The thermal properties of GMW3032M steel make it an ideal material for use in environments where extreme temperatures are a concern. GMW3032M steel has a melting point of about 1450°C and a boiling point of about 2700°C. GMW3032M steel has a density of 7.85 g/cm3.

What are the characteristics of GMW3032M steel?

The automotive industry relies on steel for a variety of components, from engine blocks and transmission housings to exhaust systems and suspension systems. But not all steels are created equal – different types have different properties that make them better suited for certain applications than others.

What types of GMW3032M steel are there?

A variety of automotive steels are used in today’s vehicles. The most common type of steel is mild steel, used in approximately 80% of automotive applications. Other types of steel used in the automotive industry include:

- High Strength Low Alloy (HSLA) Steels – Steels such as GMW3032 CR240LA may offer better mechanical properties and/or greater resistance to atmospheric corrosion than conventional carbon steels. These steels usually contain small amounts of one or more alloying elements such as copper, nickel, chromium, molybdenum, vanadium and niobium.

- Dual phase (DP) steels – such as GMW3032M-ST-S CR300DP steels, are high strength steels that contain both ferritic and martensitic microstructures. These steels typically have yield strengths in the range of 500 to 700 MPa.

- Interstitial atom-free steel (IF) – such as GMW3032 CR180IF, due to the low content of C and N in this steel, adding a certain amount of Ti and Nb makes the C and N atoms in the steel fixed as carbides and nitrides, so that There are no interstitial atoms in steel, so it is called interstitial-free steel. Interstitial-free steel has low yield point and yield strength ratio, high elongation, high plastic strain ratio, high work hardening index and other deep drawing properties, and has no aging.

What are the advantages of GMW3032M steel?

There are many benefits to using automotive steel, including its durability, strength and resistance to wear. Automotive steel is also relatively easy to machine and can be made in a variety of shapes and sizes. Additionally, automotive steel is less prone to corrosion than other types of metals, making it an ideal material for use in bodywork and other exposed areas.

What are the applications of GMW3032M steel?

GMW3032M steel is a high strength, low alloy steel commonly used in automotive applications. This steel is made by adding vanadium and molybdenum to a base of iron and carbon. This results in steel with high strength and toughness. GMW3032M also has good weldability, making it suitable for automotive body panels and other welding applications.

GMW3032M steel is an excellent material choice for many different applications. Its properties such as strength, durability, flexibility and cost-effectiveness make it ideal for a variety of uses. With its high tensile strength, corrosion resistance and weldability, GMW3032M steel can help you get the job done quickly and efficiently with results you can trust. Whether you want to build structures or manufacture mechanical components, GMW3032M steel should be your material of choice.

How to Choose the Right Automotive Steel for Your Vehicle?

There are a few things to consider when choosing the right type of automotive steel for your vehicle. The first is the intended use of the vehicle. If you’re looking for a steel that can withstand high temperatures, then you’ll want to choose a heat-resistant alloy. If you need strong and durable steel, then you’ll want to choose a high-strength alloy. The second consideration is the weight of the vehicle. Lighter steel will be more fuel efficient, while heavier steel will be more durable. The third consideration is the cost of steel. Cheaper steel may not be as strong and durable as more expensive steel, but it may suit your needs. When selecting automotive steel, it is important to consider these factors in order to choose the right type for your vehicle.

What are the divisions of steel for GM?

(1) Divided by tensile strength:

High-strength steel: TS≥340MPa (cold rolling); TS≥370MPa (hot rolling and pickling)

Ultra-high strength steel: TS>780MPa

(2) Divided by yield strength:

A high-strength steel: YS>210MPa

Ultra-high strength steel: YS>550MPa

(3) According to the metallurgical mechanism:

mild steel

Ordinary high strength steel HSS

Advanced High Strength Steel (AHSS)

Are there any different types of High Strength Steel for GM?

- Dual phase steel (DP steel, Dual Phase Steels)

- Complex phase steel (CP steel, Complex Phase Steels)

- Transformation Induced Plasticity Steels (TRIP steel, Transformation Induced Plasticity Steels)

- Martensitic steel (MS steel, Martensitic Steels)

- Quenched ductile steel (QP steel, Quenching and Partitioning Steels)

- Twinning Induced Plasticity Steels (TWIP steel, Twinning Induced Plasticity Steels)

- Boron steel (PH steel or B steel, Press Hardening/Boron Steels)

What is Dual phase steel (DP steel)?

Performance characteristics: no yield elongation, no room temperature aging, low yield ratio, high work hardening index and high bake hardening value.

Typical application: DP series high-strength steel is the preferred steel for structural parts at present, and is widely used in structural parts, reinforcement parts and anti-collision parts. For example, underbody cross members, rails, anti-collision bars, anti-collision bar reinforced structural parts, etc.

What is Composite steel (CP steel)?

Performance characteristics: fine grain, high tensile strength. Compared with the dual-phase steel of the same level of tensile strength, its yield strength is significantly higher. It has good bending performance, high hole expansion performance, high energy absorption capacity and excellent flanging forming performance.

Typical applications: chassis suspension, B-pillar, bumper, seat slide rail, etc.

What is Transformation Induced Plasticity Steel (TRIP Steel)?

Performance characteristics: The structure contains retained austenite and has good formability. During the forming process, the retained austenite gradually transforms into hard martensite, which is conducive to uniform deformation. TRIP steel also has the characteristics of high collision absorption energy, high strength plastic product and high n value.

Typical applications: parts with relatively complex structures, such as B-pillar reinforcement panels, front longitudinal beams, etc.

What is Martensitic Steel (MS Steel)?

Performance characteristics: high yield ratio, high tensile strength, relatively low elongation, need to pay attention to the tendency of delayed cracking. It has the characteristics of high collision absorption energy, high strength plastic product and high n value.

Typical applications: cold stamping of simple parts and roll-formed parts with a relatively single cross-section, such as bumpers, door sill reinforcements and anti-collision bars in side doors, etc.

What is quenched ductile steel (QP steel)?

Performance characteristics: With martensite as the matrix phase, the TRIP effect of retained austenite in the deformation process can be used to achieve higher work hardening ability, so it has higher plasticity and formability than the same level of ultra-high strength steel.

Typical application: Suitable for automotive safety parts and structural parts with complex shapes, such as A and B pillar reinforcements, etc.

What is twinning induced plasticity steel (TWIP steel)?

Performance characteristics: TWIP steel is a full austenitic steel with high C, high Mn and high Al components. Extremely high work hardening capability is achieved through twin-induced dynamic refinement. TWIP steel has ultra-high strength and ultra-high plasticity, and the strength-plasticity product can reach more than 50GPa%.

Typical application: TWIP steel has very superior formability and ultra-high strength, and is suitable for parts that have high requirements on material drawing and bulging properties, such as automotive safety parts and structural parts with complex shapes.

What is boron steel (PH steel or B steel)?

Performance characteristics: ultra-high strength (tensile strength over 1500MPa), effectively improving collision performance, lightweight body; complex shape of parts, good formability; high dimensional accuracy.

Typical application: safety structural parts, such as: front and rear bumpers, A-pillar, B-pillar, middle channel, etc.

How to choose the right type of steel for GM?

When it comes to automotive steel, there are several commonly used types. Each type has its own advantages and disadvantages, so it’s important to choose the right one for your needs.

Here are a few of the most common types of steel used in cars:

- Carbon steel: Carbon steel is the most common automotive steel. It’s durable and perfect for cars and trucks. However, it is also prone to rust and corrosion, so it needs regular maintenance.

- Alloy steel: Alloy steel is a type of steel that contains other materials, such as nickel or chromium. This makes it more resistant to rust and corrosion than carbon steel. However, it is also more expensive and harder to use.

- Stainless steel: Stainless steel is another alloy steel that contains chromium. This makes it more resistant to rust and corrosion than ordinary alloy steel. However, it is also the most expensive automotive steel.

- Galvanized steel: Galvanized steel is coated with a layer of zinc to prevent rust and corrosion. However, this coating eventually wears away over time, putting the underlying steel at risk of rust or corrosion.

- Aluminum: Aluminum is a lightweight metal that is often used in racing cars due to its low weight-to-strength ratio.