In the automotive field, lightweight has always been a hot topic. Along with the development of materials, manufacturing process, and design technology, the lightweight of automobile products is constantly breaking through, pushing up the overall performance of automobiles again and again. Today, when most consumers feel that it is very difficult to make a breakthrough in the lightweight of automobiles, Magna has shown us a series of body and chassis lightweight technologies that will be applied to automobiles in the next 5-10 years . In the future, these technologies will be adopted first in some high-end models. As a fan of Aichi Qiuzhen, it is time to learn in advance.

● Grasp Magna’s 5 body and chassis lightweight technologies in 30 seconds

1. Five-cavity unit anti-collision beam

2. Thermoformed one-piece door knocker

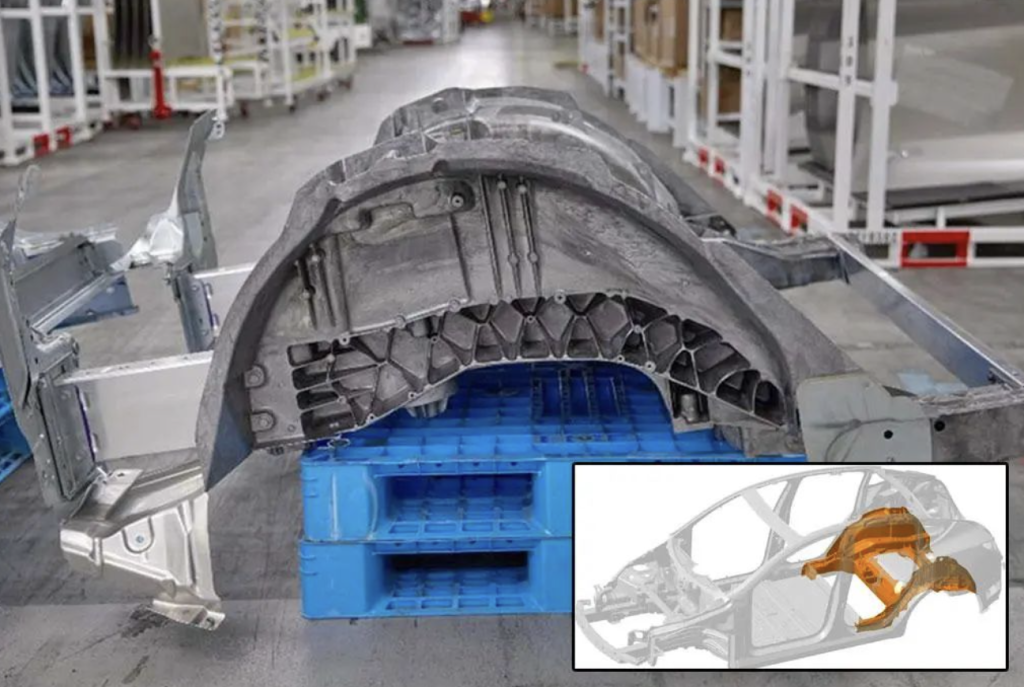

3. Integrated high pressure cast aluminum technology

4. High-pressure cast aluminum sub-frame

5. Carbon fiber composite material subframe

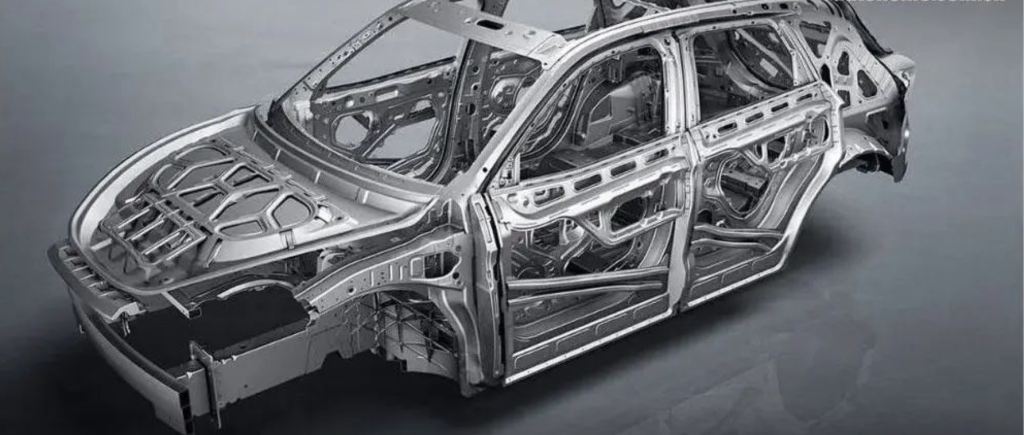

● Ways to reduce body weight

At present, there are three main ways to reduce the weight of the body chassis, which are materials, technology and design. In terms of materials, components can be reduced in weight through high-strength steel, aluminum alloys, magnesium alloys, and carbon fiber materials. Under the premise of a certain overall structural strength of the car body, the higher the proportion of high-strength steel in the car body, the less weight of steel used, thereby improving the degree of light weight, which is also a common idea in the automotive industry at present.

Through design methods such as size optimization, shape optimization, and topology optimization, the design is perfected, the integration of components is further improved, the amount of materials is reduced, and the lightweight level is finally improved. The improvement of the lightweight level allows the new car to accelerate and brake faster, handle better and be more energy-efficient.

● Five-cavity unit anti-collision beam

Friends who are concerned about safety performance will definitely know that there is an anti-collision beam behind the bumper of the car, which is the anti-collision component in frontal and rear collision accidents. Common anti-collision beams are stamped from hot-formed steel, and also have Japanese-shaped and mesh-shaped cross-sections.

The size of the cavity and the wall thickness of the cavity plate can be adjusted to meet the layout requirements of the whole vehicle. In terms of materials, this anti-collision beam can be made of 6000-7000 series aluminum profiles. Magna’s five-cavity unit anti-collision beam technology is the first in the industry, and it also provides a novel and feasible development idea for the lightweight of automobile anti-collision beams.

● Thermoformed one-piece door knocker

Friends who understand the manufacturing technology of automobile bodies should understand that the side wall of a car is not only a layer of steel plate, it is generally composed of side wall inner panels, internal reinforcements (including A-pillar reinforcement panels, B-pillar reinforcement panels, door sill reinforcement panels, and roof frames. Reinforcement plate, etc.) and body side outer cover parts are welded.

This one-piece door knocker of Magna can be stamped from 1500Mpa or 2000Mpa hot-formed steel plates, and the plates can be made of equal-thickness plates, unequal-thickness tailor-welded blanks, local spot welding patches and thickened plates, etc. It is also possible to integrate a soft area on the one-piece door knocker to achieve the effect of collision collapse and energy absorption.