Steel-made cars are the most basic common sense for modern people, but many people’s understanding of car steel is still at the stage of low-carbon steel.In fact, although both are steel, today’s automotive steel is no longer the same as the automotive steel decades ago. In recent decades, the research on steel for vehicles has been making great strides forward. The steel plates for vehicles are getting thinner and thinner, and the strength and corrosion resistance of steel have been greatly improved. In response to the impact of new materials, many steel companies are actively cooperating with automobile companies to develop lightweight high-strength steels that can compete with aluminum alloys, plastics, and carbon fiber composites.

However, in the mixed automobile market, many companies now say that they use “high-strength steel”. In fact, there is no precise definition of what grade of steel is “high-strength steel”. Its index increases with the increase in steel strength. In fact, it is similar to the “new” in the name of today’s models. What “new XX model”, “new XX model” and “new generation XX model” are all relative to the previous generation. Therefore, the marketing department of the enterprise continued to use smoke bombs to confuse the public, as long as it is above the 300Mp level, it is called “high-strength steel”. The steel called “high-strength steel” may be twice as strong.

Based on the above two points, I think we can talk about the topic of steel for vehicles. For the sake of enriching the content, I think we can start with the history of steel application.

- Brief history of steel development

In the Spring and Autumn Period and the Warring States Period, there are records about ironmaking

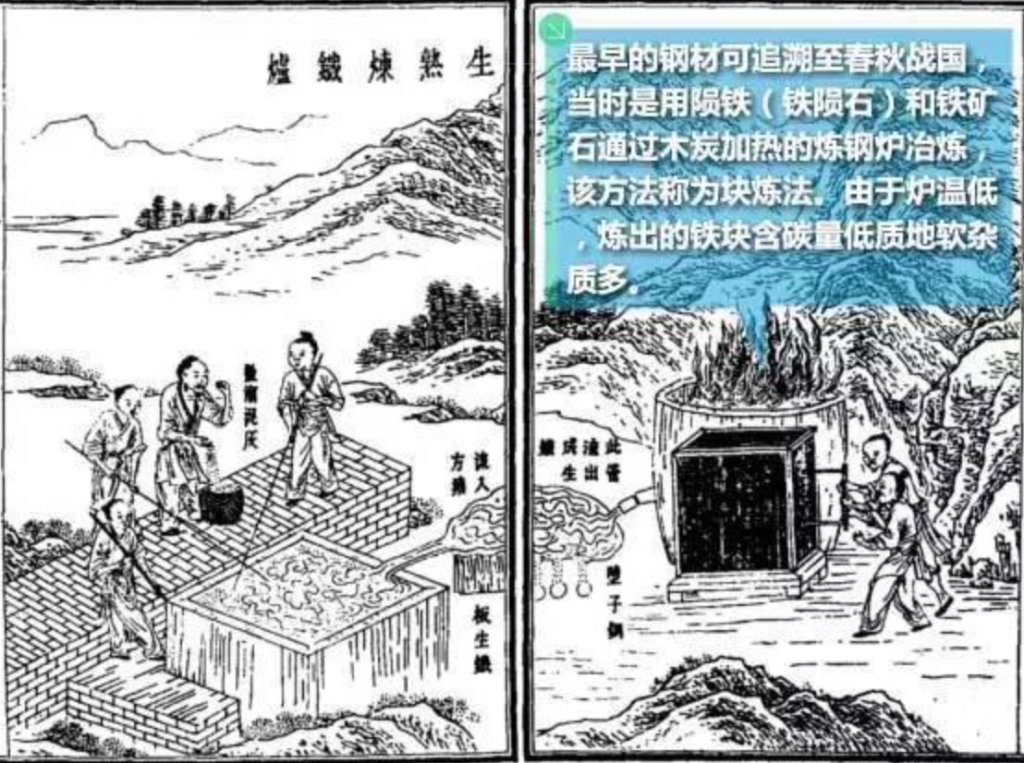

The history of steel can be traced back to the Spring and Autumn Period and the Warring States Period. There is no doubt that the dominant metal material at that time was bronze. However, whether bronze is used as a tool or a weapon, there is a problem of “brittleness”. In order to find a better alternative material, people at that time developed the early iron smelting technology. The iron smelting technology in the Spring and Autumn Period and the Warring States Period was called “block smelting method” because the smelted iron was lumpy and soft. At this time, iron ware did not have much technical advantage over bronze ware.

In the Han Dynasty, the smelting technology was improved, the upgrade of the bellows increased the furnace temperature of the iron smelting furnace, and people realized the influence of carbon on the hardness of iron, and carburizing technology began to appear. The smelting method in the Han Dynasty was called “steel frying method” because the process of stirring the molten iron in the pot and adding alloy elements during steelmaking was similar to cooking. In addition, in order to eliminate impurities, folding and forging techniques are also becoming more mature. High-quality iron was first used to make weapons, so iron weapons were unearthed in many Han Dynasty tombs.

In the next chapter, we will explain the unearthed iron swords of the Three Kingdoms period.Stay tuned!