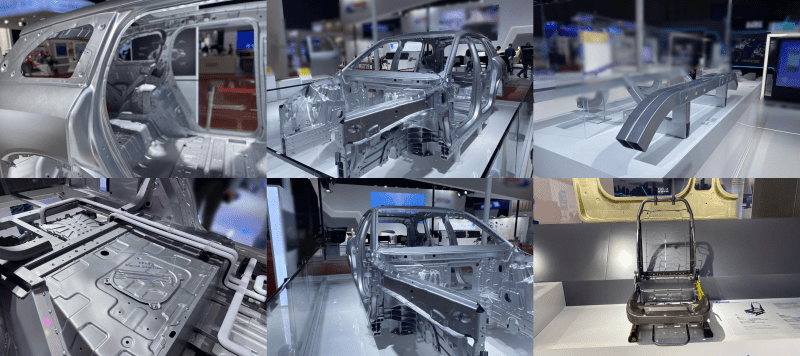

So-Lucky Steel International CO., LTD, como buen proveedor de soluciones de cadena de suministro de la serie Aluminio 6000, puede proporcionarle apertura de moldes, prueba de moldes y subcontratación de piezas posteriores producidas en masa. Varios esquemas de procesamiento, piezas de formas especiales, soldadura láser, etc.

Clasificación de la serie de aluminio 6000

Los principales productos de bobinas de aluminio de la serie 6000, 6061 contienen principalmente magnesio y silicio, por lo que integra las ventajas de la serie de aluminio 4000 y Serie 5000 de aluminio.

6061 es un producto de forja de aluminio tratado en frío, que es adecuado para aplicaciones que requieren alta resistencia a la corrosión y resistencia a la oxidación. Buena usabilidad, excelentes características de interfaz, fácil recubrimiento y buena procesabilidad. Se puede utilizar en armas de baja presión y juntas de aeronaves.

Características generales de 6061: excelentes características de interfaz, recubrimiento fácil, alta resistencia, buena facilidad de uso y fuerte resistencia a la corrosión.

Usos típicos del aluminio 6061: piezas de aviones, piezas de cámaras, acopladores, accesorios y hardware de barcos, accesorios y conectores electrónicos, hardware decorativo o varios, cabeza de bisagra, cabeza magnética, pistón de freno, pistón hidráulico, accesorios eléctricos, válvulas y piezas de válvulas.

Solución para automóviles de la serie 6000 de aluminio

Serie 6s de aluminio

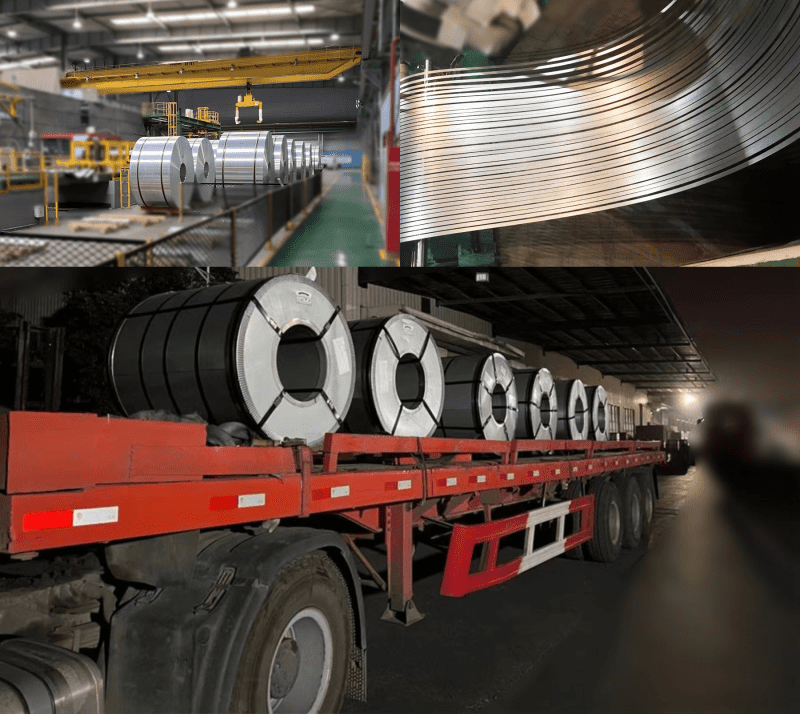

Proceso de producción, procesamiento y transporte.

Grado de aluminio de la serie 6000

| Aluminio Serie 6000 Estándar | introducir |

|---|---|

| 6S-T4/T8PB-SH-ST | actualizar |

| 6S-T4/T8PB-SH-HS | actualizar |

| 6S-T4/T8PB-SH-IB | actualizar |

| 6S-T4/T8PB-SH-IH | actualizar |

Cooperación empresarial

La compañía ahora tiene mucho personal de marketing calificado y un equipo de servicio de procesamiento calificado. Red de ventas y red de servicio de todo el país a todo el mundo. Podemos proporcionar a los clientes una excelente serie de aluminio 6000 y servicios de procesamiento rápidos y convenientes en cualquier momento.

Preguntas frecuentes sobre Aluminio serie 6000

¿Qué es el aluminio serie 6000?

Los productos de aluminio de la serie 6000 son principalmente magnesio y silicio. Resistencia media, buena resistencia a la corrosión, buen rendimiento de soldadura, buen rendimiento de proceso, buen rendimiento de oxidación y coloración. Ámbito de aplicación: la herramienta de transferencia de energía y aleación más utilizada (como el portaequipajes, la puerta, la ventana, la carrocería, el radiador, la carcasa del compartimento).

¿Cuál es la composición química del aluminio serie 6000?

Tomando como ejemplo el material de aluminio 6060, la composición química es la siguiente:

Si: 0,3-0,6

Fe: 0,1-0,3

Cu:01

Manganeso: 0,1

magnesio: 0,35-0,6

Cr:–Zn:0,1

Otros:-

Ti: 0,15

Otros totales: 0,15

Al: margen

¿Cuáles son las propiedades mecánicas del aluminio serie 6000?

Resistencia a la tracción ob (MPa): 2470

Límite elástico condicional 0,2 (MPa)

Elongación 85 (%): 26%

¿Cuáles son las características de los productos de aluminio de la serie 6000?

- Aleación tratable térmicamente de alta resistencia.

- Buen rendimiento mecánico.

- Buena usabilidad.

- Fácil de procesar y buena resistencia al desgaste.

- Buena resistencia a la corrosión y resistencia a la oxidación.

¿Cuál es el propósito principal del aluminio de la serie 6000?

: accesorios de aviación, camiones, edificios de torres, barcos, tuberías y otras aplicaciones en edificios que requieren resistencia, soldabilidad y resistencia a la corrosión. Tales como: piezas de aviones, lentes de cámara, acopladores, piezas y hardware de barcos, piezas y conectores electrónicos, hardware decorativo o varios, cabezal de cadena, cabezal magnético, pistón de freno, pistón hidráulico, piezas eléctricas, válvulas y piezas de válvulas.

¿Cuál es la diferencia entre el aluminio 6060 y el aluminio 6063?

En general, la composición química y las propiedades de procesamiento de las aleaciones 6060 y 6063 son similares, pero no exactamente iguales. La diferencia entre ellos es la fuerza. 6060 es una aleación de aluminio estándar nacional para puertas y ventanas, mientras que 6063 es una aleación de aluminio de aviación aprobada por el estado.

6063 Aluminio composición química:

Asignación de aluminio Al

Silicio Si: 0,20~0,6

Cobre Cu: 0,10

Magnesio de magnesio: 0,45 ~ 0,9

CincZn<0,10

Manganeso: <0,10

Ti: 0,10 Cr: 0,10 Fe: 0,000~0,350

Nota: simple: 0,05;

Total:<0,15

La densidad de 6063 es 2,69 g/cm3

Propiedades físicas y propiedades mecánicas:

Resistencia a la tracción ob (MPa): 205

Límite elástico condicional 0,2 (MPa): 170

Alargamiento 85 (%): 29

¿Cuáles son las características y el rendimiento de los productos de aluminio de la serie 6000?

6063 pertenece a la aleación AI-Mg-si, que es ampliamente utilizada, especialmente en la industria de la construcción. Es la aleación más prometedora. Buena resistencia a la corrosión, excelente soldabilidad, buena trabajabilidad en frío y resistencia media. Los principales elementos de aleación son el magnesio y el silicio. Tiene excelente procesabilidad, excelente soldabilidad, extrusión y galvanoplastia, buena resistencia a la corrosión, tenacidad, fácil pulido, película de color y excelente efecto anodizado. Es una aleación de extrusión típica.

Los perfiles de aleación de aluminio 6063 se utilizan ampliamente en la construcción de perfiles, tuberías de riego, tuberías, varillas y perfiles para vehículos, estantes, muebles, elevadores, cercas, etc., debido a su buena plasticidad, resistencia moderada al tratamiento térmico, buen rendimiento de soldadura y hermoso color. de la superficie después del anodizado.

¿Cuáles son las ventajas de los productos de aluminio de la serie 6000?

Sistema A-Mg-si Aleación de alta plasticidad con baja aleación. Tiene muchas características valiosas: 1. Está reforzado por tratamiento térmico, tiene dureza de alto impacto y es insensible a los defectos. 2. Tiene excelente termoplasticidad. Se puede extruir en varias formas con estructura compleja, paredes delgadas y huecos a alta velocidad. Se puede forjar en piezas forjadas con estructura compleja. El rango de temperatura de enfriamiento es amplio y la sensibilidad de enfriamiento es baja. Después de la extrusión y el desmoldeo de la forja, siempre que la temperatura sea más alta que la temperatura de enfriamiento. Se puede apagar rociando agua o penetrando agua. Las piezas de paredes delgadas (6<3 mm) también se pueden templar al aire. 3. El rendimiento de la soldadura y la resistencia a la corrosión son excelentes, y no hay tendencia al agrietamiento por corrosión bajo tensión. Entre las aleaciones de aluminio tratables térmicamente, la aleación AI-Mg-Si es la única aleación que no ha encontrado agrietamiento por corrosión bajo tensión. 4. La superficie maquinada es muy suave y fácil de anodizar y teñir.

¿Cuáles son las desventajas de los productos de aluminio de la serie 000?

Su desventaja es que si se envejece a temperatura ambiente durante un período de tiempo después del enfriamiento, afectará negativamente la resistencia.

¿Cuáles son las características del aluminio 6061?

Características generales de 6061: excelentes características de interfaz, recubrimiento fácil, alta resistencia, buena facilidad de uso y fuerte resistencia a la corrosión.

¿Cuáles son los usos del aluminio 6061?

Usos típicos del aluminio 6061: piezas de aviones, piezas de cámaras, acopladores, piezas y hardware de barcos, piezas y conectores electrónicos, hardware decorativo o varios, cabeza de cadena, cabeza magnética, pistón de freno, pistón hidráulico, piezas eléctricas, válvulas y piezas de válvulas.

¿Cuáles son los grados de la aleación de aluminio de la serie 6000?

6005, 6009, 6010, 6061, 6063, 6066, 6070, 6101, 6151, 6151, 6201, 6205, 6262, 6351, 6463, 6463, 6A02, etc.

¿Cuál es el propósito específico de la aleación de aluminio de la serie 6000??

Perfiles y tuberías extruidos 6005, utilizados para piezas estructurales que requieren una resistencia superior a la aleación 6063, como escaleras, antenas de TV, etc.

6009 panel de carrocería de automóvil

6010 hoja: carrocería de automóvil

6061 requiere diversas estructuras industriales con cierta resistencia, soldabilidad y resistencia a la corrosión, como tubos, barras, perfiles y placas para la fabricación de torres de camiones, barcos, tranvías, muebles, piezas mecánicas, mecanizado de precisión, etc. 6063 perfiles de construcción, tuberías de riego y materiales de extrusión para vehículos, plataformas, muebles, vallas, etc.

6066 Materiales extruidos para forjas y estructuras soldadas

6070 Materiales extruidos y tubos para estructuras soldadas de alta resistencia e industria del automóvil

6101 Barras de alta resistencia, conductores eléctricos y equipos disipadores de calor para autobuses

6151 se utiliza para forjar piezas de cigüeñales, piezas de máquinas y producción de anillos rodantes, lo cual es bueno para forjar

Rendimiento, alta resistencia y buena resistencia a la corrosión.

6201 barra y alambre conductor de alta resistencia

6205 placa gruesa, pedal y extrusión resistente a alto impacto

6262 Se requieren piezas roscadas de alta tensión con una resistencia a la corrosión mejor que las aleaciones 2011 y 2017

Partes estructurales extruidas de 6351 vehículos, agua, petróleo y otras tuberías de transmisión

6463 Perfiles de construcción y diversos electrodomésticos, así como decoración de automóviles con superficie brillante después del anodizado

6A02 Piezas de motores de aeronaves, piezas forjadas y troqueladas con formas complejas