SPHC Steel FAQ

What material is SPHC?

SPHC– the first S is the abbreviation of Steel, P is the abbreviation of Plate, SPHC is the abbreviation of HeatWrite, the abbreviation of C Commercial Commercial, generally means hot-rolled steel plate and steel strip as a whole. SPHC is a hot-rolled steel strip and steel plate for general use, and it is a grade in the Japanese standard JIS G 3131 standard.

What is the chemical composition of SPHC steel?

SPHC steel is made from hot rolled plate that has been pickled to remove scale. The hot rolled sheet is then passed through a cold reduction process to reduce the thickness of the material. The material is then annealed to increase the ductility of the steel. There are different grades of SPHC steel ranging from JIS G 3131-1996 to JIS G 3131-2000.

Its chemical elements include the following:

Carbon (C): less than 0.15%

Silicon (Si): less than 0.05%

Manganese (Mn): less than 0.60%

Phosphorus (P): less than 0.035%

Sulfur (S): less than 0.035%

Aluminum (Al): greater than 0.010%

These are the main chemical components contained in SPHC steel. The element content of SPHC made by different manufacturers will be slightly different, but they are all within this range.

What are the mechanical properties of SPHC steel?

SPHC steels are typically used in applications that require good formability, such as automotive parts, appliances, and furniture. The mechanical properties of SPHC steels are generally inferior to more specialized steels, but they are adequate for many applications.

Tensile strength: 270-430 MPa

Yield strength: 185-265 MPa

Elongation: 26-34% (thickness less than 3mm)

Bulk modulus: 160-200 GPa

Shear modulus: 80-110 GPa

Workers process Baosteel SPHC steel plate into strips

What are the characteristics of SPHC steel?

SPHC steels have good mechanical properties, including high tensile strength, good ductility, and excellent weldability. They also have excellent physical properties, including high hardness, good toughness, and good corrosion resistance.

How is SPHC produced?

The production process of SPHC hot-rolled strip steel is as follows:

Blast furnace hot metal——desulfurization——120t top and bottom combined blowing converter——LF refining furnace——ASP continuous casting machine——heating furnace——dephosphorization——rough rolling—finish rolling—straightening—coiling— Finished product library.

SPHC hot-rolled strip enters roughing mill process

When hot rolling is used to smelt SPHC steel grades, the sulfur content must be controlled in the molten iron pretreatment to meet the requirements of the steel grades, so as to meet the requirements of the end point of the converter and ensure that the sulfur content of the molten steel product is qualified. The target of the sulfur content of the molten iron in the desulfurization system is determined by the sulfur return at the end of the converter. Under the original process, the sulfur return of the converter is 0.016% (called 16 sulfur). In order to meet the composition requirements, the desulfurization target sulfur content was adjusted from the original 0.015% to 0.010%. In order to improve the utilization rate of magnesium powder, the injection rate of magnesium powder was adjusted from the original 12 kg/min to below 10kg/min to increase the magnesium powder in the Increase the residence time of molten iron, increase the dissolved amount, and improve the desulfurization effect of magnesium powder. When removing slag, it is required to expose at least 2/3 of the molten iron level to minimize the sulfur return of the converter caused by dirty slag removal. After adjusting the process, the sulfur return of the converter is controlled at 0.008% (called 8 sulfur). The consumption has also been reduced, providing high-quality and qualified molten iron for the operation of the converter, and reducing the desulfurization burden of the converter.

What is the heating process of SPHC?

The heating time of SPHC is based on 7-9min/cm, the heating time of 230mm billet is 3-4.5 hours; the heating time of 250mm billet is 3.5-5 hours. According to the setting requirements of finished steel plate thickness, width and rolling temperature and the speed of tapping rhythm, the temperature of each section will be adjusted appropriately within the above range. The heating temperature control table is as follows:

| brand | The heating temperature/℃ | Soaking stability

/℃ |

The billet temperature

/℃ |

|

| SPHC | The scope of | 1220-1300 | 1240-1300 | 1230-1290 |

| The target | 1250 |

*The above temperatures are reference values. Since the thickness, width and rolling temperature of the finished steel plate are different, the temperature of each section can be adjusted appropriately within the range of the above table.

How is the temperature of SPHC controlled?

SHPC will strictly control the temperature of three key points during the rolling process, namely the rough rolling exit temperature, finishing rolling temperature and coiling temperature. The temperature parameters are shown in the table below:

| brand | thickness | RT2℃ | finishing

℃ |

coiling℃ |

| SPHC | ≦2.05mm | 1080±20 | 870±20 | 710±20 |

| >2.5mm | 1060±20 | 880±20 | 710±20 |

* We will optimize and adjust the target C content according to your needs.

What are SPHCs used for?

SPHC has a wide range of uses. On the one hand, it can be used as the base material of cold-rolled steel sheets. After pickling to remove the iron scale on the surface, it can be cold-rolled and made into cold-rolled products for supply; on the other hand, sphc hot-rolled and pickled There is a huge demand for boards in the automotive industry, machinery industry, and light industry and home appliance industry

- Automobile industry:

Automobile chassis system

cab interior panel

Carriage board

Some stamped internal small parts, etc.

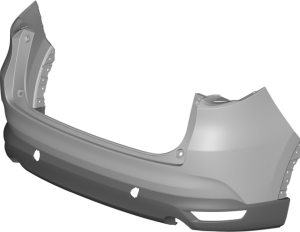

SPHC steel plate made into automobile insurance steel

- Machinery industry:

textile machinery

mine

mechanical

fan

- Light industrial appliances

compressor housing

bracket

Heater liner, etc.

- Bicycle Parts

Electrical cabinet

highway guardrail

Fence iron ladder etc.

What is the difference between SPHC and Q235?

The difference between the two is mainly in intensity. The ex-factory state of SPHC is a normalized, hot-rolled product, and its carbon content is lower than that of Q235, so the grain size of SPHC is smaller than that of Q235, so the toughness and welding performance of SPHC steel are better, but the tensile strength of SPHC is about 300MPa in terms of strength. , The tensile strength of Q235 is around 400MPa.