There are two standards for measuring the strength of steel plates, namely yield strength and tensile strength. They both represent the mechanical properties of steel plates. To put it simply, they are one of the reference factors for measuring the quality of automobile steel plates. At present, the methods for labeling the strength of automobile steel plates are not uniform in various countries around the world. Some use yield strength and some use tensile strength. The units of these two strengths are MPa, but there is a big difference in the strength of steel plates between the two standards. difference.

“Yield strength” refers to the stress of a metal material that resists slight plastic deformation. In short, yield strength is “how much force can be used to deform the metal.”

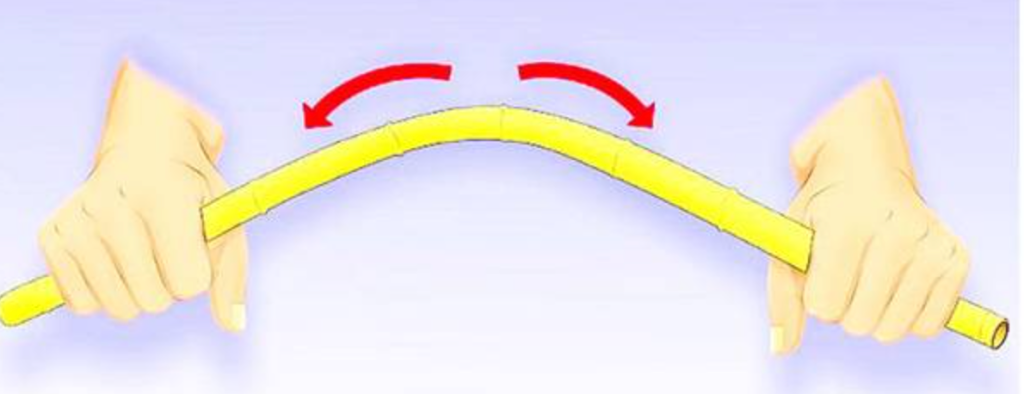

“Tensile strength” refers to the maximum stress that a metal material can withstand before breaking. In short, tensile strength is “how much force is used to break the metal.”

We all have this common sense that we can deform a thin steel plate with a small amount of force, but it is difficult to pull it off if we want to. This shows that for the same piece of material, its tensile strength is much greater than its yield strength.