BR650/780CP

What kind of steel is BR650/780CP?

BR650/780CP is a high strength cold rolled multiphase steel characterized by high strength and excellent ductility and formability. This steel is commonly used in the automotive industry for the manufacture of body and body structural parts. In its name, BR stands for “Bake Hardening Response”, which means that the steel will become harder after being baked at high temperature, improving its strength and formability. 650 and 780 respectively refer to the yield strength and tensile strength of the steel (in MPa).

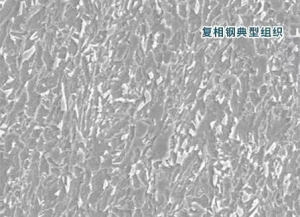

What is multiphase steel: It is mainly based on bainite and (or) ferrite structure, and usually distributes a small amount of martensite, retained austenite and pearlite structure. The grains are fine and the tensile strength is high. Compared with the dual-phase steel with the same tensile strength, its yield strength is significantly higher, and it also has the characteristics of high bending performance and hole expansion performance. This steel has a high energy absorption capacity and a high residual strain capacity.

What are the chemical composition of BR650/780CP?

Carbon (C): 0.10%~0.16%

Silicon (Si): 0.50%~1.50%

Manganese (Mn): 1.50%~2.50%

Phosphorus (P): ≤0.030%

Sulfur (S): ≤0.030%

Chromium (Cr): ≤0.30%

Molybdenum (Mo): ≤0.10%

Copper (Cu): ≤0.50%

Aluminum (Al): ≤0.10%

Titanium (Ti): ≤0.20%

What are the mechanical properties of BR650/780CP?

Yield strength: 650MPa

Tensile strength: 780MPa

Elongation: ≥12%

Impact toughness: ≥30J (-40°C)

Hardness: 180~220HB

BR650/780CP steel has high strength and excellent ductility and formability, and also has a high temper hardening response ability. In the automotive industry, this steel is commonly used in the manufacture of car bodies and car body structural parts, which can improve the strength and safety performance of the car body, reduce the weight of the car body, while maintaining good formability.

What are the advantages of BR650/780CP?

BR650/780CP multiphase steel is a high strength and toughness steel with good welding performance. Widely used in construction, transportation, machinery manufacturing and other fields.

The main advantages of BR650/780CP composite phase steel are:

- Excellent mechanical properties. This steel has high strength and toughness, and can maintain good performance under various harsh conditions.

- Good weldability. This steel is easy to weld and form, making it suitable for a variety of applications requiring welding.

- Good corrosion resistance and wear resistance. This steel has excellent corrosion and wear resistance, making it ideal for use in harsh environments or in applications where reliability is critical.

How is BR650/780CP manufactured?

BR650/780CP steel is manufactured by the following process:

Raw material preparation: Mix various raw materials according to the designed formula ratio, and perform pretreatment for subsequent process use.

Steelmaking: Using the basic steelmaking process, the raw materials are heated to a high temperature to melt them and perform deoxidation, impurity removal, blending and other operations to obtain high-quality molten steel.

Continuous casting: The molten steel obtained from steelmaking is continuously cast into slabs, and the structure and size of the slabs are controlled by adjusting the process parameters of the crystallizer.

Hot rolling: heating and rolling the slab to process it into a hot-rolled steel plate with a certain thickness.

Cold rolling: cold rolling is performed on hot-rolled steel sheets to further reduce their thickness, and a dual-phase structure is obtained by controlling the rolling process parameters.

Continuous annealing: Continuous annealing is performed on cold-rolled steel sheets to restore the plasticity and ductility of the material, and at the same time adjust the structure and properties of the steel by controlling the annealing process parameters.

Belt winding: roll the annealed steel plate into a reel for subsequent processing.

Processing and forming: Cutting, bending, welding and other processing are performed on the coiled material to make automobile body and body structural parts.

How is BR650/780CP galvanized?

The process of galvanizing BR650/780CP steel is usually divided into the following steps:

Surface treatment: The surface of BR650/780CP steel must first be cleaned and pickled to remove oxides, grease and impurities on the surface, so as to ensure the smoothness and cleanliness of the surface.

Pretreatment: After surface treatment, BR650/780CP steel coil or plate usually needs to be pretreated to facilitate the adhesion and protection of the galvanized layer. Pretreatment usually includes electrolytic cleaning, drying and other steps.

Molten ferrous galvanizing: Pass the pretreated steel coil or plate through a galvanizing machine for molten ferrous galvanizing, which is one of the most commonly used galvanizing methods. In this process, steel coils or plates are dipped in a molten ferrous galvanizing solution, and the zinc layer is attached to the steel surface by electrolysis.

Hot-dip galvanizing: Hot-dip galvanizing is another commonly used galvanizing method. Its basic principle is to immerse the pretreated steel coil or plate in molten zinc liquid, so that zinc forms a layer of zinc-iron alloy on the steel surface. layer.

Galvanizing: Galvanizing is another commonly used galvanizing method. Its basic principle is to spray zinc powder or zinc paint on the steel surface to form a zinc layer by spraying the pretreated steel coil or plate.

By galvanizing, the steel coil or plate can obtain better corrosion resistance and service life while maintaining good mechanical properties.

What are the coatings of BR650/780CP?

After BR650/780CP steel is galvanized, common coatings include:

Hot-dip galvanizing (Hot-dip zinc coating): Hot-dip galvanizing is one of the common galvanizing methods for BR650/780CP steel, and the zinc layer formed by it is mainly a zinc-iron alloy layer. This zinc layer has good corrosion resistance and adhesion, which can improve the service life and durability of BR650/780CP steel.

Electroplated zinc coating (Electroplated zinc coating): Electroplated zinc coating is a galvanizing method in which a zinc layer is plated on the surface of BR650/780CP steel by electrolysis. Different from hot-dip galvanizing, the zinc layer obtained by electro-galvanizing is mainly pure zinc layer, which has good appearance and gloss, but relatively poor corrosion resistance.

Chromium coating: Chromium plating is a coating treatment method for plating chromium on the surface of BR650/780CP steel. The chrome-plated layer has extremely strong corrosion resistance and oxidation resistance, which can improve the service life and appearance quality of BR650/780CP steel.

Nickel coating: Nickel plating is a coating treatment method for plating nickel on the surface of BR650/780CP steel. Nickel plating has excellent corrosion resistance and wear resistance, which can improve the service life and durability of BR650/780CP steel.

Alloy coating: Alloy coating is a coating treatment method in which alloy layers of different materials are plated on the surface of BR650/780CP steel. Different alloy layers have different properties, and the appropriate alloy coating can be selected according to specific application requirements to improve the service life and performance of BR650/780CP steel.

The above are the common coating types of BR650/780CP steel. Different coatings have different properties and characteristics, and the appropriate coating type can be selected according to specific application requirements.

How is BR650/780CP used as a car part?

BR650/780CP steel has high strength and formability, and is suitable for manufacturing various parts of automobiles, such as door inner panels, body support structures, suspension systems, hoods, frames and chassis, etc.

Door inner panel: BR650/780CP steel can be used to manufacture the inner door panel of automobiles. Its high strength can increase the rigidity and safety performance of the door, and its good formability can ensure the complex shape and fine appearance of the inner door panel.

Body support structure: BR650/780CP steel can be used to manufacture car body support structures, such as B-pillars, C-pillars, etc. Its high strength and good formability can improve the rigidity and stability of the body.

Suspension system: BR650/780CP steel can be used to manufacture automobile suspension systems, such as suspension arms, spring plates, etc. Its high strength can improve the load capacity and durability of the suspension system.

Engine cover: BR650/780CP steel can be used to manufacture the engine cover of the car, its high strength can improve the safety performance and durability of the engine cover, and the good formability can ensure the appearance quality of the engine cover.

Frame and chassis: BR650/780CP steel can be used to manufacture the frame and chassis of automobiles. Its high strength and excellent durability can improve the safety performance and service life of vehicles.

Contact us

If you need to purchase high-quality BR650/780CP steel, our company will be a very good choice. We have advanced production equipment and a high-level technical team, which can ensure that the BR650/780CP steel we produce has excellent mechanical properties, excellent surface quality and excellent processing performance. We can also provide you with tailor-made products and services according to the specific needs of customers to meet your different needs. Feel free to contact our customer service team, we will serve you wholeheartedly.