FIAT

So-Lucky Steel is committed to providing customers with a whole supply chain solution for the Automobile industry, GMW2M-ST-S can provide you the GMW series product to support your company or factory. You can also get more die test or mass production materials, various processing schemes, special-shaped parts, laser welding, etc. for supporting stamping parts, sheet metal parts manufacturers, and household appliances manufacturers of major automobile main engine factories.

The following of FIAT standard car model is as below:

Automobile Steel FIAT standard Grades

There are 17 kinds of FIAT standard products model in total as below.

| Model Number | Model Number |

| FEP03ZNT/F | FEE340F ZNT/F |

| FEP04ZNT/F | FEE355F ZNT/F |

| FEP05ZNT/F | FEE420F ZNT/F |

| FEP06ZNT/F | FE600DP F ZNT/F |

| FEE180IFZNT/F | FE800DP F ZNT/F |

| FEE210IF ZNT/F | FE700TR F ZNT/F |

| FEE220BH ZNT/F | FE1000DP F ZNT/F |

| FEE270FZNT/F | FE1200DP F ZNT/F23 |

| FEE315F ZNT/F |

FIAT standard Business Cooperation

If you are interested with our automotive steel coil or sheet/plate to FIAT standard at So-Lucky Steel, get more FIAT standard steel price and information here. we will answer you as soon as possible.

Steel for Fiat FAQS

What is the classification of Steel for Fiat?

According to the characteristics of the production process, it is divided into hot-rolled steel plate, cold-rolled steel plate and coated steel plate.

In terms of strength, it can be divided into ordinary steel plates (mild steel plates), low-alloy high-strength steel plates (HSLA), ordinary high-strength steel plates (high-strength IF steels, BH steels, phosphorus-containing steels, and IS steels), etc. ) and Advanced High Strength Steel (AHSS).

What are the requirements for Steel for Fiat?

Different parts have different requirements for steel plates:

- Panel parts: Panel parts require the plate to have good formability, strength, ductility, dent resistance and corrosion resistance.

- Structural components: Structural components require plates with good formability, strength, impact energy absorption capacity, durability, corrosion resistance and weldability.

- Walking part: The running part requires the plate to have good formability, rigidity, fatigue resistance, corrosion resistance and weldability.

What is the performance of Steel for Fiat?

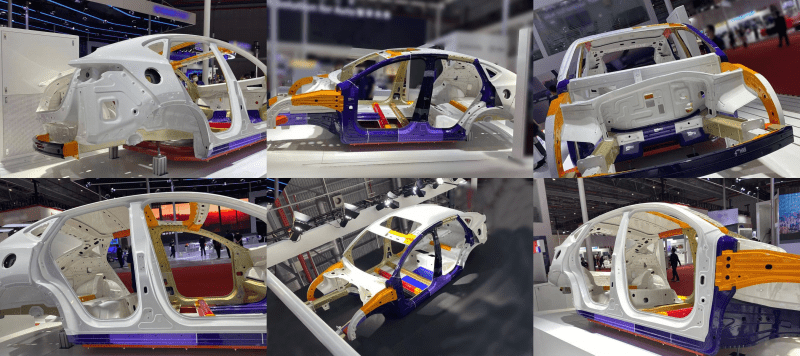

The components that make up the vehicle body are broadly classified into panel components, structural components, running components, and reinforcement components. These components correspond to different application requirements and have different performances. For example, panel parts require the board to have good formability, strength, extensibility, dent resistance, corrosion resistance, etc.; structural parts require the board to have good formability, strength, impact energy absorption capacity, fatigue durability, and corrosion resistance , Weldability; Walking parts require good formability, rigidity, fatigue durability, corrosion resistance, and weldability; and excellent collision energy absorption capacity and weldability are particularly important for reinforced parts.

What are the uses of Steel for Fiat?

Luggage, medical equipment, motorcycle shell; car, bus inner roof, instrument panel; seat back, door panel, window frame, etc.

What types of high-strength steel are used for Steel for Fiat?

- Dual phase steel (DP steel, Dual Phase Steels)

- Complex phase steel (CP steel, Complex Phase Steels)

- Transformation Induced Plasticity Steels (TRIP steel, Transformation Induced Plasticity Steels)

- Martensitic steel (MS steel, Martensitic Steels)

- Quenched ductile steel (QP steel, Quenching and Partitioning Steels)

- Twinning Induced Plasticity Steels (TWIP steel, Twinning Induced Plasticity Steels)

- Boron steel (PH steel or B steel, Press Hardening/Boron Steels)

What are the deep processing technologies of Steel for Fiat?

Laser tailor welded blank and continuously variable section panel technology

Laser welded blanks (Tailor Welded Blanks, TWB) use laser as the welding heat source to combine and weld a number of steel, stainless steel, aluminum alloy materials of different materials, different thicknesses, and different coatings into a whole sheet.

Using laser tailor welding technology, according to the stress of structural parts, materials of different thicknesses and strength levels can be reasonably combined to improve the structural rigidity while reducing the weight of parts, and also improve the utilization of materials and reduce parts. The number of parts in the machine simplifies the process. Tailored laser welding technology has become the main technical means of automobile lightweight, and has been applied in the models of many manufacturers. It is mainly used in front and rear door inner panels, front and rear longitudinal beams, side panels, floor panels, A, B, C pillars inside the doors, wheel housings and trunk inner panels, etc.

Continuous variable section plate (Tailor Rolling Blanks, TRB) is also called differential thickness plate, which means that during the rolling process of the steel plate, the size of the roll gap is changed in real time through the computer, so that the rolled thin plate has a predetermined thickness along the rolling direction. Custom variable cross-sectional shapes.

Continuously variable cross-section panel technology has been widely used in the manufacture of body structural parts, such as hood panels, B-pillars, body chassis, motor spacer guide rails, inner panels of middle pillars, fenders and crash boxes, etc., and has been successfully applied to Audi, BMW, Volkswagen, GM and other models.

Tailored laser welding and continuously variable cross-section technology change the thickness of stamping raw materials through different technological means, and are used to solve the problem that different parts have different load-carrying capacity requirements when auto parts are loaded. Compared with the two, the advantage of laser tailor welding technology is its flexibility, which can realize splicing at any position and splicing of different materials. The advantage of continuously variable section technology is that there is no weld seam, the hardness change along the length direction is relatively gentle, it has better formability, and the surface quality is good, the production efficiency is high, and the cost is low.

Internal high pressure forming technology

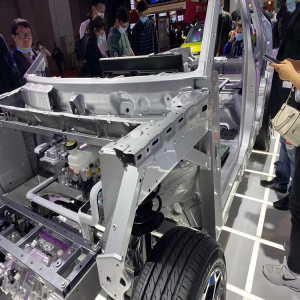

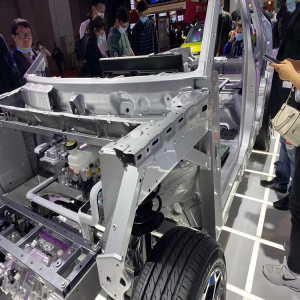

Internal high pressure forming technology (Internal High Pressure Forming) is a kind of thin plate hydroforming technology. It uses seamless pipe fittings or welded pipe fittings as raw materials. The technology of deforming in the mold to obtain the desired shape of the part.

This technology is used to manufacture chassis parts such as sub-frames, or engine system parts such as intake pipes and exhaust pipes, etc., and use closed pipes instead of welded cavity structural parts to avoid performance degradation and quality caused by welding In addition, one part can replace the welded assembly of multiple stamping parts, greatly reducing the processing steps, so it is widely used in the automotive industry.

Since the prototype car roof bracket and side door beam in the ultra-light car body project ULSAB (Ultra Light Steel Auto-Body) were produced using the internal high pressure forming technology, many models have adopted this technology to produce automotive structural parts. Although this technology started relatively late in my country, it has made remarkable progress in recent years.