Color Coated Steel

Color coated steel is the plate obtained by taking cold-rolled steel strip and galvanized steel strip (electro galvanized and hot-dip galvanized) as the substrate on the continuous unit, after surface pretreatment (degreasing and chemical treatment), coating one or more layers of liquid paint by roll coating, and then baking and cooling.

Because the coating can have various colors, it is customary to call the coated steel plate color coated steel plate. Because the coating is carried out before the forming and processing of steel plate, it is called precoated steel plate in foreign countries.

Color Coated Steel Advantage

Color coated steel plate is an organic coating applied to the steel surface. It has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, convenient processing and forming, and can also reduce the cost and pollution.

Color Coated Steel Development

Since the establishment of the first continuous coating steel plate line in the United States in 1935, color coated steel plates have been widely used. There are a wide variety of color coated plates, about more than 600 kinds. Color coated plates have the advantages of both organic polymers and steel plates. They have not only the good coloring, formability, corrosion resistance and decoration of organic polymers, but also the high strength and easy processability of steel plates, which can be easily processed such as stamping, cutting, bending and deep drawing. This makes the products made of organic coated steel plate have excellent practicability, decoration, processability and durability.

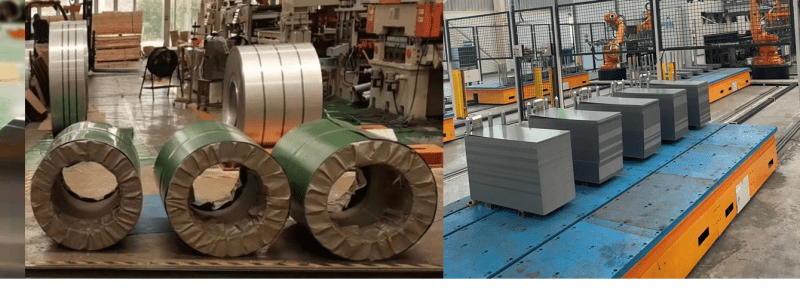

Color Coated Steel Coils Factory

Color Coated Steel Products

The base plate of color coated plate adopts high-quality hot-dip galvanized plate, hot-dip aluminum zinc plate, electro galvanized plate and cold-rolled plate. The coating adopts polyester, silicon modified polyester, high durability polyester (HDP) and polyvinylidene fluoride (PVDF) produced by famous coating manufacturers at home and abroad. Combined with advanced management and technology and experience in color coated plate production, various color coated plates with excellent quality and beautiful appearance can be produced. In addition, It can also produce embossed board and printing board. Color coated board is widely used because of its excellent molding performance, durability and colorful colors.

Color coated plate and aluminum zinc plated plate are very new environmental protection products, which represent the development direction of green and environmental protection new materials in the future. As a consensus of mankind, reducing carbon emissions and protecting the earth are new topics we are facing at present and even in the future.

Color Coated Steel Application

Color Coated Steel is widely used in various fields, such as construction, machinery, household appliances and coating industries because of its good surface flatness, finish, high stamping performance and dimensional accuracy, and its non-aging, low yield point and good stamping performance.

The delivery condition

Follow the delivery condition for color coated Steel, the category of color coated steels includes color coated steel coils and color coated steel plate.

Color Coated Steel Delivery

You can see more factory about color coated Steel as below.

Color Coated Steel Prices

Color coated Steel Prices is mainly determined by steel coil weight, packaging mode, transportation distance and delivery way and other factors.

1. how to measure the weight of steel plate or coil?

The nominal weight of the coils is as weighted. For the asrolled coils, the weight range differs according to the lines.

The available weight increases when the width increases. The available weight is listed as following:

Color coated steel coils price: parameter*width*Unit Price

Color coated steel sheet/plate price: width*length*thickness*parameter*number of sheets*Unit Price

2. packaging mode

the different packaging mode will affect the final price. if you are not sure about the packaging mode, we can give you the professional advice.

3.transportation distance and delivery way

So-Lucky can provide you the variety delivery way, for instance, train, plane, ship or automobile. The delivery time is also important for you, if you ensure the transportation distance and delivery way of color coated steel.

If you are interested with our color coated steel coil or sheet/plate, get more color coated steel price here. we will answer you as soon as possible.

FAQ About color coated steel

What is color coated steel ?

Color-coated steel refers to color-coated steel plate. Color-coated steel plate is a kind of steel plate with organic coating. The traditional coating can be divided into several categories. The top grade is fluorocarbon coating, which can resist corrosion for almost 20 years. Generally, they are distributed from steel mills to various places in the form of drums. The color steel plate we often see refers to the processed plate with a thickness of about 50~100mm. It is composed of the filler in the middle and the color steel plate on both sides. Among them, the thickness of color plate is 0.4mm, 0.5mm, 0.6mm and other different thicknesses, and the middle layer can be polyurethane, rock wool or foam plastic.

What is the process flow of color coated steel?

Color-coated steel plate is a product made of cold-rolled steel plate and galvanized steel plate after surface pretreatment (degreasing, cleaning, chemical conversion treatment), continuous coating (coating method), baking and cooling. The main production process of the common two-coating and two-drying continuous color coating unit is: uncoiling, pretreatment, coating, baking, post-processing and coiling.

What are the types of color coated steel plate substrate?

- Cold-rolled substrate color coated steel plate

The color plate produced from the cold-rolled substrate has a smooth and beautiful appearance and has the processing performance of cold-rolled plate; However, any small scratch on the surface coating will expose the cold-rolled substrate to the air, which will quickly generate red rust at the exposed iron. Therefore, such products can only be used for temporary isolation measures and indoor materials with low requirements

- Hot-dip galvanized color coated steel plate

The product obtained by coating the organic coating on the hot-dip galvanized steel plate is the hot-dip galvanized color coated plate. In addition to the protection of zinc, the organic coating on the surface of hot-dip galvanized color-coated plate also plays the role of insulation protection and rust prevention, and its service life is longer than that of hot-dip galvanized plate. The zinc content of hot-dip galvanized base plate is generally 180g/m2 (the maximum zinc content of hot-dip galvanized base plate for external use of double-sided buildings is 275g/m2.

- Hot-dip aluminium-zinc color coated plate

According to requirements, hot-dip aluminium-zinc steel plate can also be used as color coating substrate (55% AI-Zn and 5% AI-Zn)

- Electrogalvanized color coated plate

The product obtained by baking with the electro-galvanized sheet as the base plate and coated with organic coating is the electro-galvanized color coated sheet. Because the zinc layer of the electro-galvanized sheet is thin and the zinc content is usually 20/20 g/m2, this product is not suitable for outdoor production of walls, roofs, etc. However, due to its beautiful appearance and excellent processing performance, it can be mainly used in household appliances, audio, steel furniture, interior decoration, etc.

What is the composition of color coated steel?

Color-coated steel is made of hot-dip galvanized steel substrate or aluminum-zinc sheet as substrate, and coated with water-based fluorocarbon paint or polyester paint on both sides. After baking, carry out surface protection treatment, such as printing or embossing.

What are the properties of color coated steel?

1) Good adhesion: the coating and substrate are firmly combined.

2) Good flexibility: bending, rolling, stamping and deep drawing.

3) Good corrosion resistance: coating protects steel from corrosion.

4) Good wear resistance: the coating has good wear resistance and can be used for a long time.

5) Good weather resistance: the coating has good weather resistance and can withstand ultraviolet radiation, high temperature and rain.

What are the advantages of color coated steel?

There are many advantages of using color coated steel in construction and other projects. The most obvious benefit is the aesthetic attraction of materials. Color-coated steel can add a unique appearance to any project, and different colors can create interesting visual effects.

In addition to visual appeal, color-coated steel is also very durable. The coating protects the steel from corrosion and wear, and can also improve the service life of the steel. This makes it an ideal material for projects requiring long-term durability.

Color-coated steel is also easy to maintain. The coating does not need regular maintenance and can be cleaned with simple soap and water. This makes it an ideal material for projects requiring low maintenance costs.

In conclusion, color coated steel is the best choice for various applications. It is durable, easy to maintain, has a unique appearance, can enhance any project.

What are the disadvantages of color coated steel?

Color-coated steel has some disadvantages. One is that it may be more expensive than traditional steel. Another reason is that the color will fade over time, especially under direct sunlight or other strong light. Finally, color-coated steel may be more difficult to machine than traditional steel, because color will make it more difficult to see welds and other defects.

What are the coating methods of color coated steel?、

There are two ways of color coating steel: pre-coating and post-coating. Pre-painted steel refers to the paint that has been applied to the steel before it forms its final shape. Post-painted steel is the paint applied after the steel forms its final shape. Both types of color coated steel have their own advantages and disadvantages.

Pre-coated steel is more durable than post-coated steel because it is less likely to crack, flake or flake. It is also easier to clean and maintain because paint forms a barrier between metal and environment. However, pre-painted steel is more expensive than post-painted steel, and it is difficult to repair if damaged.

Post-painted steel is cheaper than pre-painted steel, and can be easily repaired if damaged. However, it is not as durable as pre-painted steel, and is easier to crack, peel or peel off. Since paint does not form a barrier between metal and environment, cleaning and maintenance are also more difficult.

Color-coated steel is a good way to add modern appearance to any building or structure. With its rich colors, finishes and coatings, you can customize the perfect color scheme according to your needs. Color-coated steel also provides excellent protection against the passage of air and light. It is durable, easy to maintain, recyclable and affordable – all these are important features of building durable structures in an environmentally friendly way.