Stainless steel 200 Series: Cr Mn Ni

So-Lucky Steel provide you the stainless steel 200 series, with ss201 and ss202 as a China stainless steel supplier with good quality and warmly service online.

Classification of Stainless steel 200 Series

According to its metal structure, stainless steel can be divided into five categories: austenitic stainless steel, ferritic stainless steel, AUSTENITIC FERRITIC (duplex) stainless steel, martensitic stainless steel and precipitation hardening stainless steel.

stainless steel 201,202 and other 200 series stainless steel: Manganese instead of nickel has poor corrosion resistance and is widely used as a cheap substitute for 300 Series in China. According to its chemical composition, austenitic stainless steel is divided into two series: chromium nickel series ( stainless steel 300 Series in the United States) austenitic stainless steel and chromium manganese series (200 Series stainless steel in the United States).

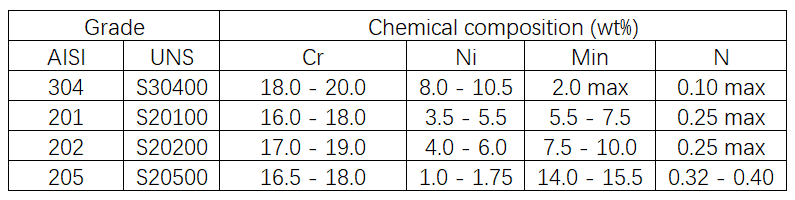

Stainless Steel Grade

200 Series Stainless steel Application

stainless steel 200 series is widely used in the market, such as building components, decorative parts, vehicle structures, guardrails, household appliance components and shells, newspaper kiosks, telephone kiosks, catering appliances, medical appliances, etc. the stainless steel is mainly austenitic stainless steel. Coupled with a large number of industrial applications, the output (or consumption) of austenitic stainless steel accounts for about 75% ~ 80% of the total output (or consumption) of stainless steel.

stainless steel 200 series application

Stainless steel 200 series(ss 200) Type and Difference

| Type/Element Share | C | Mn | P | Si | Cr | Ni | S | N | Cu |

|---|---|---|---|---|---|---|---|---|---|

| 201 stainless steel(201 ss) | <=0.15 | <=7.5-10.0 | <=0.060 | <=1.0 | 17.0-19.0 | 4.00-6.00 | <=0.03 | <=0.25 | – |

| 202 Stainless steel(202 ss) | <=0.15 | 5.5-7.5 | <=0.060 | <=0.75 | 13.5-15.0 | 1.02-1.28 | <=0.03 | <=0.25 | Semi copper 0.8% High copper 1.5% |

If you are interested with our Stainless steel 200 Series coil or sheet/plate, get more price and product information here. we will answer you as soon as possible.

FAQ About 200 series stainless steel

What is 200 series stainless steel?

Stainless steel is an alloy of iron, carbon and chromium. It has a wide range of applications in many industries, from auto parts to kitchen appliances. However, with so many choices, it is difficult to know which stainless steel is most suitable for your project.

Stainless steel is a high alloy steel containing at least 10.5% chromium. They are divided into different series according to their alloy composition. The most commonly used series in the production of stainless steel products are 200, 300, 400 and 600 series.

200 series stainless steel is austenitic steel containing manganese and nitrogen. These steels cannot be hardened by heat treatment and are therefore not suitable for use in high temperature applications. 300 series stainless steel is austenitic steel containing chromium and nickel. These steels have good corrosion resistance and can be hardened by cold work. 400 series stainless steel is ferritic steel containing chromium and carbon. These steels can be hardened by heat treatment and have good corrosion resistance. 600 series stainless steel is martensitic steel containing chromium and silicon. These steels can be hardened by heat treatment, but their corrosion resistance is poor.

What are the characteristics of 200 series stainless steel?

200 series austenitic chromium nickel manganese alloy has high ductility, corrosion resistance and weldability. These alloys cannot be hardened by heat treatment.

The nickel content in stainless steel series is very low, usually about 8%, which is a material with strong corrosion resistance. This alloy is also nonmagnetic, which makes it very suitable for applications where magnetism is not ideal. In addition, the series stainless steel has high chromium content, which makes it have excellent oxidation resistance and corrosion resistance.

What is the current situation of “200 series” stainless steel?

Stainless steel is divided into austenitic stainless steel

Ferritic stainless steel, austenitic-ferritic (duplex) stainless steel, martensitic stainless steel and precipitation hardening stainless steel. A large amount of stainless steel circulating on the market is mainly austenitic stainless steel, which is used to make building components, decorative parts, vehicle structures, guardrails, household electrical components and shells, newspaper booths, telephone booths, catering appliances, medical appliances, etc. Combined with a large number of industrial uses, the output (or consumption) of austenitic stainless steel accounts for about 75%~80% of the total output (or consumption) of stainless steel. According to its chemical composition, austenitic stainless steel can be further divided into two series: chromium-nickel series (300 series in the United States) austenitic stainless steel and chromium-manganese series (200 series in the United States) austenitic stainless steel. Chromium-nickel (300-series) austenitic stainless steel takes nickel as the main austenitizing element. They have excellent corrosion resistance and good comprehensive mechanical properties, technological properties and weldability in a variety of corrosive media, so they have a wide range of applications in chemical, petroleum, marine, food, light industry and other fields.

What are the disadvantages of “200 series” stainless steel?

The steel strength and hardness of 200 series stainless steel are low, so it is not suitable for use on equipment and parts that bear heavy loads and have high requirements for hardness and wear resistance. Chromium series (200 series) austenitic stainless steel is developed on the basis of chromium-nickel series austenitic stainless steel by adding and/or replacing precious metal nickel with nitrogen. Its austenitizing elements include nitrogen in addition to manganese, and generally there is an appropriate amount of chromium (about 4%~6%). Steel plays a role in stabilizing austenite. Because nitrogen strongly forms and stabilizes austenite and plays a good role in solid solution strengthening, which improves the strength of austenitic stainless steel, this series of stainless steel is suitable for use on equipment and components that bear heavy loads and have low corrosion resistance requirements.

What is the difference between 200 series stainless steel and 300 series stainless steel?

Among the brands applicable to automobile production, the first steel grade is 201, which is generally used for moulding, piston ring, exhaust valve, automobile fastening parts, etc. 200 series stainless steel is a good austenitic steel: the first is good performance. The 200 series austenitic stainless steel is equivalent to the 300 series in corrosion resistance, strength and service life, but its surface brightness, color and color are slightly lower than those of the 300 series. Second, the cost is low. The 200 series stainless steel has increased the manganese content and nitrogen content in the smelting process. These two elements have replaced nickel, reducing the nickel content to 2.5%~5%, and its cost is 15%~20% lower than that of the 300 series. Therefore, 200 series stainless steel is also known as “stainless steel for the poor”, which indicates that it is cheap stainless steel; Third, the practical 200 series is similar to the 300 series, and can be applied in many fields. Because of its low price, it is particularly suitable for developing countries that lack nickel resources.

What is the typical use of 200 series stainless steel?

Because of its good plasticity and high corrosion resistance, it can be used for the following purposes:

- Food processing

Utensils, kitchen equipment, food processing machinery, filters, storage milk cans, drinking water containers

- Durable consumer goods:

Washing machine parts, water heater, steel furniture

- Architecture and architectural decoration

Door and window frame, handrail, shelf, column, car ceiling, telephone

- Automobile, rail and transportation

Wheel cover, structural parts, windshield wiper, trailer, tipper, decorative accessories, etc.

- However, they may be brittle and less ductile than austenitic steel. Because of their hardness, they are often used for knives and surgical instruments.

How to deal with rusty spots on stainless steel?

- In chemical method, acid cleaning paste or spray is used to assist the rusted parts to passivate again to form chromium oxide film to restore their corrosion resistance. After acid cleaning, in order to remove all pollutants and acid residues, it is very important to wash properly with clean water. After all treatment, re-polish with polishing equipment and seal with polishing wax. For parts with slight rust spots, the 1:1 mixture of gasoline and engine oil can also be used to wipe the rust spots with a clean rag.

- Mechanical sandblasting, shot blasting with glass or ceramic particles, annihilation, brushing and polishing. It is possible to wipe away the pollution caused by previously removed materials, polishing materials or obliterated materials by mechanical methods. All kinds of pollution, especially foreign iron particles, may become the source of corrosion, especially in humid environment. Therefore, the mechanically cleaned surface should preferably be formally cleaned under dry conditions. The use of mechanical method can only clean its surface and cannot change the corrosion resistance of the material itself. Therefore, it is recommended to re-polish with polishing equipment after mechanical cleaning, and seal with polishing wax.