CR220I

What is isotropic steel?

Isotropic steel is a steel that has the same physical and mechanical properties in all directions. This means that material properties such as strength, ductility and toughness are the same in all directions.

In contrast, anisotropic materials have different properties in different directions. For example, wood is an anisotropic material because it has different strength and stiffness in different directions due to the orientation of its wood fibers.

Isotropic steel is usually produced by a process called hot rolling, which involves heating the steel to high temperatures and then passing it through a series of rolls to form it into the desired shape. This process helps ensure that the steel has a uniform microstructure and properties in all directions.

Isotropic steels are commonly used in structural and mechanical applications where consistent properties in all directions are important, such as the construction of buildings, bridges and vehicles.

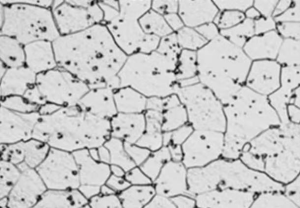

Typical microstructure of isotropic steel

How is CR220I isotropic steel manufactured?

CR220I isotropic steel is manufactured through a process known as Electric Arc Furnace (EAF) steelmaking. The process involves melting steel scrap and other raw materials in electric arc furnaces, which are then refined and cast into various shapes and forms.

The exact manufacturing process for CR220I isotropic steel may vary by manufacturer, but generally involves the following steps:

Raw Materials: Raw materials used to manufacture CR220I isotropic steel typically include steel scrap, iron ore, and other alloying elements such as copper, silicon, and manganese.

Melting: The raw material is melted in an electric arc furnace, which is heated by an electric arc between the electrodes and the metal charge. The melting process helps to remove impurities and refine the steel.

Casting: Once the steel is melted and refined, it is cast into various shapes and forms using a continuous casting process. The steel is poured into a water-cooled mold, which helps the steel solidify and form a continuous strand.

Rolling: The continuous strand is then rolled into various shapes and sizes using a hot rolling process. The process involves passing the steel through a series of rollers, which help shape the steel and create it to the desired dimensions.

Annealing: After the hot rolling process, the steel is usually annealed to improve its ductility and other mechanical properties. The process involves heating the steel to a specific temperature and then allowing it to cool slowly.

Further processing: CR220I isotropic steel can be further processed using various methods such as cold rolling, forming, welding and heat treating to obtain the properties and dimensions required for a specific application.

The manufacturing process of CR220I isotropic steel involves a combination of melting, casting, rolling, and other processing methods to produce a strong, durable, and versatile material suitable for a variety of industrial applications.

What are the characteristics of CR220I isotropic steel?

CR220I is a high-strength steel with many desirable properties, including:

High Strength: CR220I has a minimum yield strength of 220 megapascals (MPa) and a minimum tensile strength of 340 MPa, making it stronger than many other types of steel.

Good Formability: Despite its high strength, CR220I is also relatively easy to form into different shapes and sizes, making it a popular choice for a wide range of applications.

Good weldability: CR220I can be easily welded using common techniques such as gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW).

Corrosion resistance: CR220I has good corrosion resistance and is suitable for use in harsh environments.

Cost-effective: CR220I is relatively cost-effective compared to other high-strength steel alloys, making it an attractive option for manufacturers seeking a balance of performance and cost.

CR220I is a versatile and durable material that offers many desirable properties for a variety of applications.

What is the chemical composition of CR220I isotropic steel?

The chemical composition of CR220I steel may vary slightly depending on the specific manufacturer or supplier, but in general it usually contains the following elements:

Carbon (C): 0.08% max

Manganese (Mn): 1.60% max

Phosphorus (P): 0.025% max

Sulfur (S): 0.015% max

Silicon (Si): 0.50% max

Copper (Cu): 0.30% max

Niobium (Nb): 0.05% max

Vanadium (V): 0.10% max

Other trace elements may also be present in small amounts. This composition provides a balance of strength, toughness and weldability, making CR220I suitable for a variety of structural applications in the automotive, construction and industrial sectors.

What are the mechanical properties of CR220I isotropic steel?

The mechanical properties of CR220I isotropic steel depend on the specific manufacturing process, but the following are typical values for this steel grade:

Yield strength: 220 MPa

Tensile strength: 340 MPa

Elongation: 34%

Elastic modulus: 200 GPa

Poisson’s ratio: 0.3

Charpy impact toughness: 80 J at -20°C

High strength and good elongation make CR220I steel suitable for structural applications that require both strength and ductility, such as chassis frames and suspension components in the automotive industry. The Charpy impact toughness value indicates that a steel can withstand sudden impacts and shocks without breaking, which is important for safety-critical components.

How hard is CR220I isotropic steel?

The hardness of CR220I isotropic steel depends on the specific heat treatment and processing it has undergone, but in general, this steel is not considered to be particularly hard compared to other steel grades. Hardness is usually measured using the Rockwell or Brinell scales, and values may vary depending on the specific test method and conditions.

However, the strength of CR220I isotropic steel is higher, the minimum yield strength is 220MPa, and the minimum tensile strength is 340MPa. These values indicate the steel’s ability to resist deformation and withstand high stress without cracking or fracturing. So while CR220I may not be particularly hard when it comes to hardness measurements, it is still a strong and durable material suitable for a wide range of structural and industrial applications.

What is the corrosion resistance of CR220I isotropic steel?

CR220I isotropic steel has good corrosion resistance due to its composition including elements such as copper and silicon. These elements help improve the steel’s resistance to corrosion and oxidation, especially in harsh environments.

In addition, CR220I steel can be further improved by coating or surface treatment such as galvanizing, electroplating or powder coating. These coatings provide an additional layer of corrosion protection that can extend the life of the steel.

However, it is important to note that, like all steels, CR220I isotropic steel remains susceptible to corrosion when exposed to corrosive environments such as salt water, acidic or alkaline solutions, or high humidity. Therefore, to ensure the long-term durability and performance of CR220I isotropic steel in corrosive environments, proper measures such as proper maintenance, cleaning and protection need to be taken.

What are the uses of CR220I isotropic steel in automobiles?

CR220I isotropic steel is commonly used for structural and safety components in the automotive industry due to its high strength and good formability. Some specific uses of CR220I isotropic steel in automobiles include:

Chassis frame: CR220I is commonly used in the production of chassis frames due to its strength and ability to withstand stress and impact.

Suspension components: CR220I is also used for suspension components that require strength and ductility, such as control arms, strut towers, and stabilizer bars.

Safety components: CR220I is used to produce a variety of safety components, including door beams, pillars and roof structures, which help protect occupants in the event of a collision.

Exhaust system: CR220I is also used in the production of exhaust systems, including mufflers and pipes, because of its good high temperature resistance and corrosion resistance.

Overall, CR220I isotropic steel is a versatile material widely used in automotive applications, providing strength, durability and safety in a cost-effective manner.

Overall, the process properties of CR220I isotropic steel make it a versatile and easy-to-use material for a variety of manufacturing processes, especially those involving forming and welding.

SOLUCKY STEEL TRADING CO.,LTD is a professional steel supplier. As the designated dealer of Baosteel, Masteel, Shougang, and VAMA designated agreement users, it pays more attention to product quality. The company strictly selects high-quality raw materials, with fine workmanship and mature technology. We attach great importance to product quality issues, and professionals strictly control every process of product production and processing. Its products have the characteristics of strong corrosion resistance, high plasticity, durability, and not easy to deform, so it is a very good choice. At the same time, we insist on building a close relationship with our customers at the lowest price. We firmly believe that we will bring every customer super high satisfaction in terms of quality, price and service. If you are looking for automotive steel similar to CR220I, you can contact us and look forward to cooperating with you!