Phase transformation induced plasticity steel – CR380/590TR

What is Phase Transformation Induced Plasticity Steel?

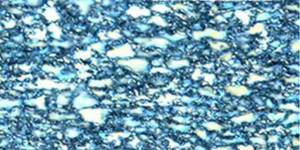

The microstructure of phase transformation induced plasticity steel is ferrite + bainite + retained austenite, and the retained austenite transforms into martensite during the forming process, thereby enhancing the plastic deformation ability of the material and achieving relatively high strength and plasticity. Good unity. The material has the characteristics of high n value, good formability, high impact absorption energy and so on.

Typical Microstructure of Phase Transformation Induced Plasticity Steel

Does CR380/590TR belong to phase transformation induced plasticity steel?

CR380/590TR is a typical cold-rolled transformation-induced plasticity steel material. Due to its excellent combination of strength, formability and energy absorption properties, this steel is commonly used in various applications in the automotive industry. The “CR” in CR380/590TR stands for cold rolled, which means that the steel has been processed at low temperature to improve mechanical properties. “380/590” refers to the steel’s minimum yield strength and tensile strength, respectively, measured in megapascals (MPa). “TR” stands for Transformation Induced Plasticity and refers to the mechanism by which steels acquire their unique properties.

Transformation Induced Plasticity (TRIP) steels are designed to undergo a phase change during deformation, resulting in improved strain hardening capability and energy absorption. This improves crash performance, reduces weight and improves formability compared to conventional steel.

Overall, CR380/590TR steel is a highly advanced multifunctional material that is widely used in various applications in the automotive industry, such as body structures, safety components, chassis components and powertrain components.

What are the characteristics of CR380/590TR steel?

CR380/590TR phase transformation induced plasticity steel is a new type of high strength and toughness structural steel. It has excellent properties such as high strength, high toughness, good weldability, good formability and low temperature toughness. The main characteristic of this steel is its unique microstructure consisting of a large number of fine grains and a small amount of acicular ferrite. This microstructure endows steel with excellent properties such as high strength, high toughness, good weldability and good formability.

What is the chemical composition of CR380/590TR phase transformation induced plasticity steel?

CR380/590TR is an advanced high strength steel with excellent mechanical properties such as high strength and formability. This steel contains several elements that contribute to its unique properties.

The chemical composition of CR380/590TR phase transformation induced plasticity steel usually includes:

Carbon (C): 0.12% – 0.20%

Manganese (Mn): 1.50% max

Silicon (Si): 0.50% max

Chromium (Cr): 0.30% max

Molybdenum (Mo): 0.10% max

Vanadium (V): 0.15% max

Nitrogen (N): 0.008% – 0.025%

Aluminum (Al): 0.01% – 0.10%

Other trace elements may also be present in smaller amounts. Exact chemical composition may vary slightly by manufacturer and intended application.

What are the mechanical properties of CR380/590TR phase transformation induced plasticity steel?

CR380/590TR phase transformation induced plasticity steel has excellent mechanical properties, including high strength, good ductility and high formability. The following are some typical mechanical properties of this steel:

Tensile strength: 380 – 590 MPa

Yield strength: 280 – 420 MPa

Elongation: 27% – 36%

Uniform elongation: 15% – 25%

Total elongation: 30% – 40%

Strain hardening exponent (n value): 0.20 – 0.25

Hole expansion rate: 60% – 70%

Bending angle: 180°

These properties make CR380/590TR phase transformation induced plasticity steel ideal for parts in the automotive industry that require high strength and good formability, such as chassis components and reinforcements, suspension components and seat frames.

What is the process flow of CR380/590TR steel?

The production of CR380/590TR steel involves several steps, including:

Melting: Steel is produced in Electric Arc Furnaces (EAFs), where scrap metal and other raw materials are melted and refined to produce the desired chemical composition.

Casting: Once steel is melted and refined, it is cast into slabs or billets. This is done by pouring molten steel into molds, which then cools and solidifies.

Hot Rolling: The cast steel is then reheated and hot rolled at high temperatures into sheets or coils. Hot rolling reduces the thickness of the steel and improves its mechanical properties.

Cold rolling: After the steel is hot rolled, it is cold rolled at a lower temperature to further reduce the thickness and improve the surface finish. Cold rolling also increases the strength and formability of the steel.

Annealing: Cold-rolled steel is annealed by heating it to high temperatures and then cooling it slowly to improve its ductility and formability. The annealing process also helps to remove any residual stresses in the steel.

Galvanizing: Finally, steel can be galvanized by applying a layer of zinc to the steel. This helps improve its corrosion resistance and durability.

What coating types are available for CR380/590TR steel?

There are three coating types for CR380/590TR steel:

- Galvanized layer: CR380/590TR+EG

- Hot-dip galvanized layer: CR380/590TR+GI

- Hot-dip galvanized iron alloy: CR380/590TR+GA

What are the benefits of using CR380/590TR Phase Transformation Induced Plasticity steels in automotive manufacturing?

CR380/590TR Phase Transformation Induced Plasticity Steel is an advanced high strength steel commonly used in various applications in the automotive industry. Here are some of its functions in automobile manufacturing:

Improved Crash Performance: CR380/590TR Phase Change Induced Plasticity Steel is known for its excellent energy absorption properties and is ideal for use in vehicle crash areas. It helps absorb impact energy and reduces damage to the vehicle and its occupants in the event of a crash.

Lightweight: One of the main advantages of using CR380/590TR phase change induced plasticity steel is its high strength to weight ratio. This steel is much stronger than conventional steel, yet lighter in weight, making it an ideal material for the automotive industry’s lightweighting initiatives. By reducing vehicle weight, fuel efficiency can be improved and emissions reduced.

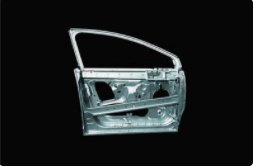

Formability: CR380/590TR phase transformation induced plasticity steel has high formability, which means it can be easily formed into complex geometries during the manufacturing process. This makes it ideal for use in a variety of automotive parts that require complex shapes, such as door panels, roofs and hoods.

Corrosion Resistance: This steel is also known for its excellent corrosion resistance, which is important for automotive applications. The use of CR380/590TR phase transformation induced plasticity steel in auto parts helps to prolong the service life of vehicles and reduce maintenance costs.

Overall, the use of CR380/590TR transformation-induced plasticity steels in automotive manufacturing offers a range of advantages, including improved crash performance, lightweight, formability and corrosion resistance.

What are the applications of CR380/590TR phase transformation induced plasticity steel in automobile manufacturing?

CR380/590TR Transformation Induced Plasticity (TRIP) Steel is an Advanced High Strength Steel (AHSS) with many applications in automotive manufacturing. Some common applications include:

Body in white: CR380/590TR steel is used for the body structure of the vehicle, including roof, floor and side panels. The steel’s high strength-to-weight ratio helps improve the crashworthiness and reduce weight of vehicles.

Safety components: The steel is also used in the production of various safety components such as seat frames, seat belts and airbag housings. These components require high strength and stiffness to protect vehicle occupants in the event of a crash.

Chassis components: CR380/590TR steel is used to produce various chassis components, such as suspension components, steering components, subframes, etc. These components require high strength and durability to withstand the stress and strain of everyday use.

Powertrain components: The steel is also used to produce various powertrain components such as engine mounts, transmission mounts and exhaust systems. These components require high strength, stiffness and corrosion resistance to ensure reliable performance throughout the life of the vehicle.

SOLUCKY Iron and Steel Trading Co., Ltd. is a professional steel supplier. As the designated dealer of Baosteel, Masteel, Shougang, and VAMA designated agreement users, it pays more attention to product quality. The company strictly uses high-quality raw materials, meticulous workmanship, and mature technology. We are very Pay attention to product quality issues, and have professionals strictly check every process of product production and processing. Its products have the characteristics of strong corrosion resistance, high plasticity, durability and not easy to deform, so it is a very good choice. At the same time, we adhere to the close relationship with customers at the lowest price. We firmly believe that we will bring every customer super high satisfaction in terms of quality, price and service. If you are looking for CR380/590TR similar automotive steel, you can contact us and look forward to cooperating with you!