CR450/950 Steel

What is the miCRostructure of twinning induced plasticity steel?

Twin-induced plasticity (TWIP) steel is a high-strength steel that exhibits excellent ductility and strength due to the twinning mechanism. The miCRostructure of TWIP steel is characterized by a single-phase austenite structure.

The unique properties of TWIP steels arise from the interaction of dislocations and deformation twins. Deformation twins are CRystal defects that form in response to plastic deformation and consist of mirror-image regions of the lattice separated by twin boundaries. These twins act as obstacles to dislocation motion and inCRease resistance to deformation. In TWIP steel, the existence of a large number of stacking faults and partial dislocations promotes the formation and propagation of deformation twins.

What are the product characteristics of twinning induced plasticity steel?

TWIP steel is a fully austenitic steel with high C, high Mn and high Al components. Extremely high work hardening capability is achieved through twin-induced dynamic refinement. TWIP steel has ultra-high strength and ultra-high plasticity, and the strength-plasticity product can reach more than 50GPa%.

What kind of steel is CR450/950TW?

CR450/950TW is a high strength steel that belongs to twin induced plasticity (TWIP) steels. It is a dual-phase steel specifically designed to combine high strength with excellent formability and ductility.

The designation CR450/950TW refers to the strength of the steel, expressed in terms of yield strength and tensile strength. CR450/950TW has a yield strength of 450 MPa and a tensile strength of 950 MPa. This high strength is achieved through a combination of chemical composition and miCRostructural design.

The miCRostructure of CR450/950TW steel is characterized by a fine-grained matrix of ferrite and bainite, and a small amount of retained austenite. The steel is also rich in alloying elements such as carbon and manganese, which promote the formation of deformation twins during plastic deformation.

CR450/950TW steel is mainly used in the automotive industry for the manufacture of lightweight structural components such as chassis and body-in-white components. The perfect combination of strength, formability and ductility makes it an ideal material for these applications as it can help reduce weight and improve fuel efficiency without saCRificing safety or performance.

What are the characteristics of CR450/950T steel?

CR450/950TW steel is a high strength steel that offers several advantages over conventional steels, including:

High Strength: CR450/950TW steel has a high strength-to-weight ratio, making it ideal for lightweight structures that require high strength.

Excellent formability: CR450/950TW steel is highly formable, meaning it can be easily formed into complex shapes using standard forming techniques such as bending and deep drawing. This makes it suitable for applications where the material must be able to form complex shapes.

Good ductility: CR450/950TW steel is highly ductile, which means it can withstand significant deformation without breaking. This makes it suitable for applications where the material must be able to absorb energy during impact or shock loading.

Excellent fatigue resistance: CR450/950TW steel has excellent fatigue resistance, meaning it can withstand repeated load cycles without CRacking or breaking.

Enhanced CRashworthiness: CR450/950TW steel has enhanced CRashworthiness, which means it can absorb more energy during a CRash than conventional steel. This helps reduce the risk of occupant injury in the event of a collision.

Improved Fuel Efficiency: CR450/950TW steel helps improve fuel efficiency by reducing vehicle weight without saCRificing safety or performance.

Reduced emissions: Using CR450/950TW steel in vehicles can help reduce emissions by improving fuel efficiency and reducing vehicle weight.

CR450/950TW steel combines high strength, excellent formability, good ductility and enhanced CRashworthiness, making it an ideal material for lightweight automotive construction.

What is the chemical composition of CR450/950TW steel?

The chemical composition of CR450/950TW steel may vary by manufacturer and specific product grade, but generally contains the following elements:

Carbon (C): 0.15% – 0.25%

Silicon (Si): 0.10% – 0.50%

Manganese (Mn): 1.20% – 2.50%

Phosphorus (P): < 0.025%

Sulfur (S): < 0.010%

Chromium (CR): 0.50% – 1.00%

Nickel (Ni): 0.30% – 0.50%

Copper (Cu): <0.30%

Aluminum (Al): < 0.050%

Nitrogen (N): < 0.005%

These elements are carefully balanced to achieve the required properties of steel such as high strength, excellent formability and good ductility. In particular, the addition of alloying elements such as chromium and nickel helps to promote the formation of deformation twins in the process of plastic deformation, so that the steel has high strength and excellent ductility.

What are the mechanical properties of CR450/950TW steel?

The mechanical properties of CR450/950TW steel vary according to the specific product grade and manufacturing process, but the following are typical values:

Yield strength: 450 – 600 MPa

Ultimate tensile strength: 950 – 1200 MPa

Elongation at break: 15 – 30%

Uniform elongation: >10%

Total elongation: > 25%

Hardness: 200 – 300 HV

Fatigue strength: > 300 MPa

Is CR450/950TW steel hard enough?

CR450/950TW steel is a high-strength, high-plasticity steel with unique miCRostructure and excellent mechanical properties. While this steel is relatively hard compared to conventional mild steels, it is not as strong as some other high-strength steels, such as hardened tool steels or high-speed steels.

The hardness of CR450/950TW steel depends on several factors including its chemical composition, heat treatment and manufacturing process. Typically, the steel has a hardness of around 200-250 HV (Vickers hardness), which is relatively high for a steel that is both ductile and formable. However, it is not as hard as some other high-strength steels, which can have a Vickers hardness value of 500 or higher.

What are the supply standards for CR450/950TW steel?

Supply standards for CR450/950TW steel may vary by manufacturer and specific product grade, but the following are commonly used standards:

EN 10338: This is a European standard that specifies requirements for cold-formed and hot-rolled flat products made of high-yield-strength multi-phase steels. The standard covers several steel grades, including CR450/950TW.

ASTM A1011: This is an American standard that specifies requirements for hot-rolled carbon steel sheets and strips, including high-strength low-alloy steels. The standard covers several grades of steel, including some like CR450/950TW.

JIS G 3113: This is a Japanese standard that specifies requirements for hot-rolled steel plates, sheets, and strips for automotive structures. The standard covers several grades of steel, including some like CR450/950TW.

In addition to these standards, we have negotiated and determined the specific supply standards of CR450/950TW steel according to your needs.

What are the main uses of CR450/950TW steel in automobiles?

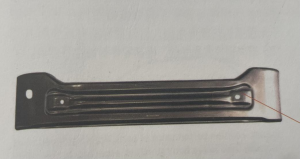

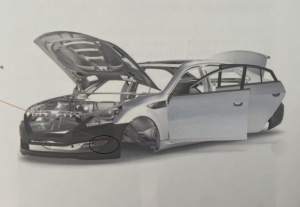

Front bumper made of CR450/950TW steel (the picture below is the specific position in the car)

TWIP steel has very superior formability and ultra-high strength, and is suitable for parts with high requirements on material drawing and bulging properties, such as automotive safety parts and structural parts with complex shapes.

Some of the major uses of CR450/950TW steel in automobiles include:

Structural parts: CR450/950TW steel is often used in automotive structural parts, such as chassis, beams, suspension parts, etc. Steel’s high strength and ductility make it ideal for these applications because it can withstand heavy loads and impacts without deforming or breaking.

Safety components: CR450/950TW steel is also used in automotive safety components, such as door beams, side anti-collision beams, seat frames, etc. The high strength and ductility of this steel make it an excellent choice for these applications as it absorbs and distributes impact energy to protect occupants in the event of a CRash.

Exhaust systems: CR450/950TW steel is sometimes used in automotive exhaust systems because of its excellent resistance to high temperature oxidation and corrosion. The high strength and ductility of this steel also make it ideal for exhaust components that need to withstand vibration and other stresses.

Wheels: CR450/950TW steel is also sometimes used in automotive wheels because it has excellent fatigue strength and can withstand repeated load cycles without CRacking or breaking.

CR450/950TW steel is a versatile material that can be used in a wide range of applications in the automotive industry where strength, ductility and durability are key factors.

How long is the CR450/950TW useful?

The service life of CR450/950TW steel is dependent on a number of factors including the specific application, operating conditions and level of care and maintenance. However, in general, CR450/950TW steels are expected to last longer due to their high strength, ductility, and resistance to deformation and fracture.

The steel’s unique miCRostructure and excellent mechanical properties make it ideal for a variety of applications in the automotive industry, such as structural components, safety components, exhaust systems and wheels. In these applications, steel is exposed to a variety of operating conditions, including vibration, shock, high temperature and corrosive environments. However, due to its high strength and excellent resistance to deformation and fracture, CR450/950TW steel is able to withstand these conditions and maintain its properties over time.

In addition, the steel’s resistance to corrosion and high-temperature oxidation helps to further extend its service life, as it can withstand the effects of moisture, salt and other corrosive agents without degrading or losing its mechanical properties.