The meaning of HC180B

HC180B is a specific grade of bake-hardening steel that is commonly used in the automotive industry. The “HC” in the grade name stands for “high-strength, cold-rolled” steel. The “180” in the grade name refers to the minimum yield strength of the steel, which is 180 megapascals (MPa). The “B” at the end of the grade name indicates that the steel has been bake-hardened, which means that it has been processed to increase its strength through age hardening.

What is Bake Hardening Steel?

Bake-hardened steel is a type of steel that is specifically designed for use in automotive outer coverings. It is made by retaining a certain amount of solid solution carbon and nitrogen atoms in the steel during production. Additionally, strengthening elements such as phosphorus and manganese are added to further increase its strength.

After the steel is processed and formed into its final shape, it is baked at a certain temperature. This process is known as age hardening, and it serves to increase the yield strength of the steel. Age hardening occurs because the retained carbon and nitrogen atoms form clusters within the steel during the baking process, which in turn strengthens the steel.

The organization of bake-hardened steel is primarily ferrite. Ferrite is a type of iron crystal structure that is known for its softness and ductility. By adding strengthening elements and utilizing age hardening, however, the strength of the ferrite can be greatly increased, making it suitable for use in automotive outer coverings.

What is Bake Hardening Steel?

Bake-hardened steel is a type of steel that is specifically designed for use in automotive outer coverings. It is made by retaining a certain amount of solid solution carbon and nitrogen atoms in the steel during production. Additionally, strengthening elements such as phosphorus and manganese are added to further increase its strength.

After the steel is processed and formed into its final shape, it is baked at a certain temperature. This process is known as age hardening, and it serves to increase the yield strength of the steel. Age hardening occurs because the retained carbon and nitrogen atoms form clusters within the steel during the baking process, which in turn strengthens the steel.

The organization of bake-hardened steel is primarily ferrite. Ferrite is a type of iron crystal structure that is known for its softness and ductility. By adding strengthening elements and utilizing age hardening, however, the strength of the ferrite can be greatly increased, making it suitable for use in automotive outer coverings.

Performance parameters and chemical composition of HC180B

Chemical composition of HC180B:

C(MAX): 0.06

Mn(MAX): 0.7

Si(MAX): –

Mechanical properties of HC180B:

YS(MPa): 180-230

TS(MPa): 290-360

EL(%) ≥34

r ≥ 1.6

n ≥ 0.17

BH2(MPa) ≥ 30

What are the advantages of HC180B?

There are several advantages of using HC180B in the automotive industry:

High Strength: HC180B has a high yield strength of at least 180 MPa, making it ideal for use in applications that require high strength and rigidity, such as automotive body parts.

Good Formability: Despite its high strength, HC180B also exhibits good formability, which means it can be easily shaped and formed into various complex shapes without cracking or deforming. This makes it a popular choice for outer body panels and other parts that require good formability.

Bake Hardening: The bake-hardening process used during production further increases the strength of HC180B, making it even more resistant to deformation and ensuring long-term durability.

Cost-effective: HC180B is a cost-effective solution compared to other high-strength materials, making it an attractive choice for manufacturers looking to reduce costs without sacrificing quality.

Common applications of HC180B

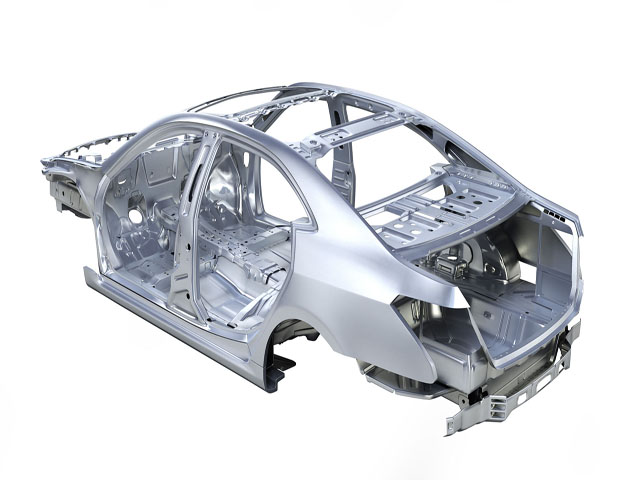

HC180B is a specific grade of bake-hardening steel that is commonly used in the automotive industry. Its high strength, good formability, and resistance to deformation make it an excellent choice for a variety of automotive applications, including outer body panels, structural components, and other parts that require strength, rigidity, and durability. Some common applications of HC180B in the automotive industry include the production of body panels, such as doors, hoods, fenders, and trunks, as well as the manufacture of structural components, such as cross members, chassis, and suspension parts. Additionally, HC180B can also be used for manufacturing various other automotive components, including bumpers, brackets, and reinforcements.