HC300/500DPD+Z

The introduction of HC300/500DPD+Z

HC300/500DPD+Z is a high-strength dual-phase steel, also known as high-strength low-alloy steel, where “DPD” stands for dual-phase steel, a material composed of two different metal grains. This steel has high strength, high ductility and excellent formability, and is widely used in automobile manufacturing, construction, machinery manufacturing and other fields. Among them, “HC” stands for hot rolling products, “300” stands for the minimum tensile strength of 300MPa, “500” stands for the minimum yield strength of 500MPa, “+Z” stands for the steel surface after hot-dip galvanizing treatment, with excellent corrosion resistance. In the automobile manufacturing industry, HC300/500DPD+Z steel is usually used in automobile body structures and safety components, such as doors, roofs, chassis, etc., to improve the safety, durability and energy-saving performance of automobiles.

The chemical composition of HC300/500DPD+Z generally meets the following range:

- Carbon content (C): 0.10%-0.20%

- Silicon content (Si): ≤0.50%

- Manganese content (Mn): 1.0%-2.5%

- Phosphorus content (P): ≤0.030%

- Sulfur content (S): ≤0.015%

- Aluminum content (Al): ≥0.015%

- Titanium content (Ti): ≥0.020%

- Niobium content (Nb): ≥0.010%

- Chromium content (Cr): ≤0.30%

- Nickel content (Ni): ≤0.50%

The main performance of HC300/500DPD+Z includes:

High strength: The minimum yield strength is 500MPa, and the minimum tensile strength is 300MPa, which is higher than ordinary low-carbon steel and ordinary high-strength steel.

Excellent formability: steel has good plasticity and ductility, and can be easily processed into various shapes.

Good corrosion resistance: After hot-dip galvanizing, a zinc layer with excellent corrosion resistance is formed on the surface of the steel, which can effectively prevent corrosion and oxidation of the steel.

Excellent welding performance: steel can be welded by conventional welding methods, such as arc welding, gas shielded welding, etc.

Low-temperature cold deformation performance: At low temperatures, steel has good toughness and plasticity, and is not prone to cold and brittle phenomena, so it is suitable for use in low-temperature environments.

What part of the car is HC300500DPD+Z generally used for?

HC300/500DPD+Z steel is generally used in automobile body structure and safety components, such as:

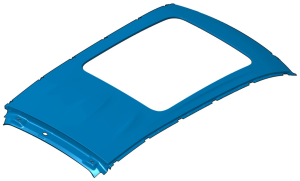

Body structural parts: Body structural parts mainly include doors, roof, rear cover, front cover, body side shell, etc. These parts have high requirements on the overall rigidity, torsional rigidity and rollover resistance of the vehicle. HC300/500DPD+Z steel has high strength, high plasticity and good formability, which can meet the use requirements of these parts.

Safety components: Safety components mainly include chassis, bridges, front and rear suspensions, door brackets and other components, which have high requirements on the safety, durability and energy-saving performance of automobiles. HC300/500DPD+Z steel has high tensile strength and yield strength, which can improve the strength and stiffness of these components, thereby improving the safety and durability of the car. At the same time, the low carbon content of this steel can also reduce the weight of the vehicle and improve the energy-saving performance of the vehicle.

How is HC300500DPD+Z galvanized?

HC300/500DPD+Z steel is hot-dip galvanized, and the specific process is as follows:

Steel coil surface treatment: first pickling and degreasing the steel coil surface to remove surface grease, oxides and other impurities.

Preheating: Send the surface-treated steel coil into the preheating furnace to heat the steel coil to increase the temperature of the steel.

Hot-dip galvanizing: The preheated steel coil is sent into the molten zinc solution for dipping, so that the zinc solution covers the surface of the steel to form a zinc layer. During this process, the steel reacts with the molten zinc to form an alloy layer that protects the surface of the steel.

Cooling: The galvanized steel coil is cooled by a cooler to reduce the temperature of the steel coil to below room temperature.

Coating treatment: Coating treatment is carried out on the surface of the steel coil after hot-dip galvanizing to improve the corrosion resistance and aesthetics of the steel.

Through the above process, after HC300/500DPD+Z steel is hot-dip galvanized, a zinc layer will be formed on the surface, which can well protect the steel surface from oxidation and corrosion, thereby prolonging the service life of the steel.

The process flow of HC300/500DPD+Z steel production is as follows:

Smelting raw materials: First, iron ore and other alloying elements, such as chromium, nickel, molybdenum and other raw materials, need to be added to the blast furnace for smelting to obtain high-quality steel billets.

Continuous hot rolling: the smelted billet is heated and then rolled by a hot rolling mill to transform the billet into steel plates, steel strips, steel pipes and other products of different specifications and sizes. During this process, the scale and rust on the steel surface are removed by machine cutting to obtain a clean steel surface.

Pickling treatment: Send the hot-rolled steel plate, steel strip and other materials into the pickling tank for pickling treatment to remove the scale and rust on the surface, so as to obtain a smooth and clean steel surface.

Heat annealing: send the pickled steel into the heating furnace for heat annealing to remove stress and improve the plasticity and toughness of the material, so that the steel has better formability.

Cooling treatment: Send the steel after heating and annealing into the cooler for cooling treatment to stabilize the structure of the steel and increase the hardness, so that the steel has better strength and toughness.

Galvanizing treatment: Hot-dip galvanizing is performed on the cooled steel to form a layer of zinc to protect the surface of the steel from oxidation and corrosion.

Coating treatment: Finally, the surface of the galvanized steel is coated to improve the corrosion resistance and aesthetics of the steel.

Through the above process, HC300/500DPD+Z steel is processed through multiple processes to obtain products with high strength, high plasticity and good formability, which are widely used in automobile manufacturing and other fields.

Contact us

If you need to purchase high-quality HC300/500DPD+Z steel, our company will be a very good choice. We have advanced production equipment and a high-level technical team, which can ensure that the HC300/500DPD+Z steel we produce has excellent mechanical properties, excellent surface quality and excellent processing performance. We can also provide you with tailor-made products and services according to the specific needs of customers to meet your different needs. Feel free to contact our customer service team, we will serve you wholeheartedly.