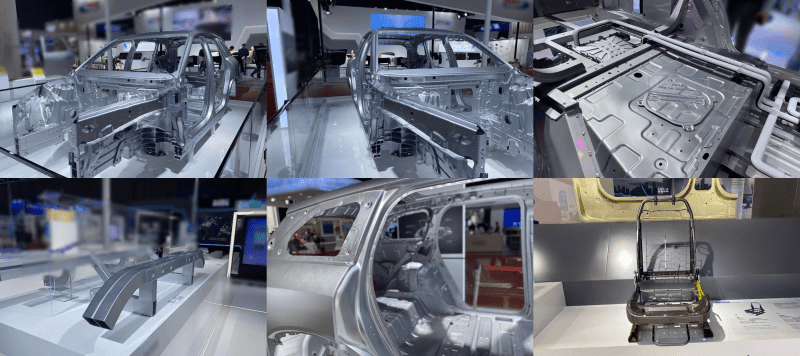

So-Lucky Steel International CO., LTD, as a good China supplier of Aluminum 5000 series supply chain solutions, can provide you mold opening, mold trial and outsourcing of later mass-produced parts about Aluminum products. Various processing schemes, special-shaped parts, laser welding, etc.

Aluminum 5000 Series

The main Aluminum 5000 Series Coils products include 5052.5005.5083.5a05 series.

Aluminum 5000 series coils belongs to the commonly used alloy aluminum coils series. The main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum magnesium alloy.

The main features are low density, high tensile strength and high elongation. Under the same area, the weight of aluminum magnesium alloy is lower than that of other series Therefore, it is often used in aviation, such as aircraft fuel tank. It is also widely used in conventional industry.

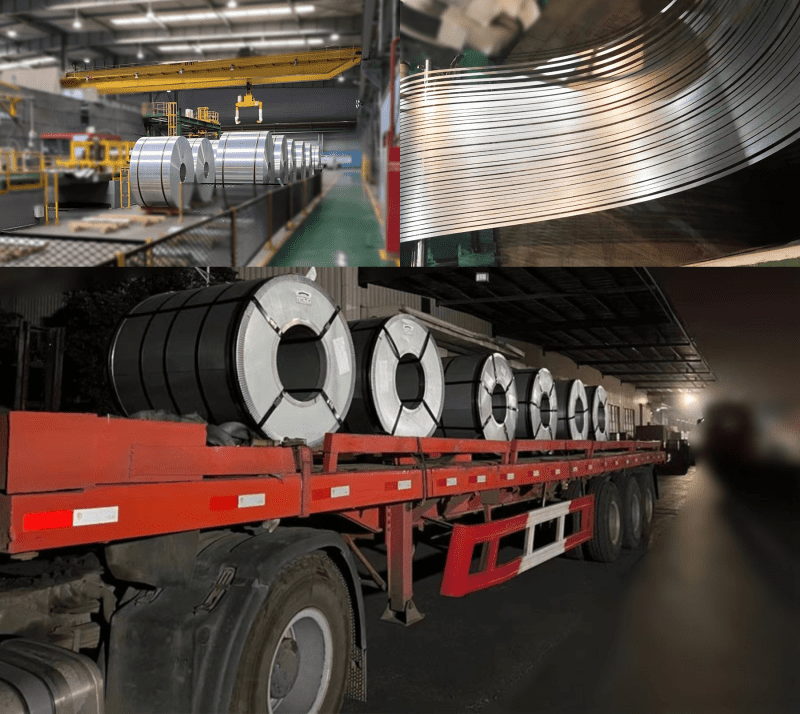

The processing technology is continuous casting and rolling, which belongs to the hot-rolled aluminum plate series, so it can do deep oxidation processing. In China, Aluminum 5000 series plate is one of the more mature aluminum plate series.

Aluminum 5000 Series automobile solution

Aluminum 5000 Series

Production, processing and transportation process

Aluminum 5000 Series automobile solution

5S-O-SH-ST

5S-O-SH-HF

Business Cooperation

The company now has many skilled marketing personnel and a skilled processing service team. Sales network and service network from all over the country to all over the world. We can provide customers with excellent Aluminum 5000 series products and fast and convenient processing services at any time.

5000 Series Aluminum FAQS

What is 5000 series aluminum alloy?

Aluminum based alloys. The main alloy elements include copper, silicon, magnesium, zinc and manganese, and the secondary alloy elements include nickel, iron, titanium, chromium, lithium, etc.

Aluminum alloy has low density, but high strength, close to or better than high-quality steel, good plasticity, and can be processed into various profiles, with excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in industry, and its usage is only less than that of steel.

What structural material does 5000 series aluminum alloy belong to?

5000 series aluminum alloy belongs to non-ferrous metal structural material.

The 5000 series aluminum alloy has low density, but its strength is relatively high, close to or higher than that of high-quality steel, good plasticity, and can be processed into various profiles, with excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in industry, and its usage is only less than that of steel. Some aluminum alloys can be heat treated to obtain good mechanical properties, physical properties and corrosion resistance.

What are the grades of 5000 series aluminum alloy?

The grades of 5000 series aluminum alloy include:

5005, 5050, 5052, 5056, 5083, 5086, 5154, 5182, 5252, 5254, 5356, 5454, 5456, 5457, 5652, 5657, 5A02, 5A03, 5A06, 5A05, 5A06, 5A12, etc.

What is the chemical composition of 5000 series aluminum?

Let’s take 5005 aluminum alloy as an example to introduce the chemical composition of 5000 series aluminum:

Aluminum Al: residual silicon Si: ≤ 0.30

Copper Cu: ≤ 0.20

Magnesium Mg: 0.50~~1.1

Zinc Zn: ≤ 0.25

Manganese Mn: ≤ 0.20

Chromium Cr: ≤ 0.10

Iron Fe: 0.000~0.700

Note: single: ≤ 0.05;

Total: ≤ 0.15

What are the mechanical properties of 5000 series aluminum?

The mechanical properties of 5005 aluminum alloy are as follows:

tensile strength σ b(MPa): 155~195

Conditional yield strength σ 0.2(MPa):≥125

elongation δ 5(%):≥2

Note: Sample size of tensile mechanical properties of strip at room temperature: strip thickness>0.8~1.3

What is the delivery status of 5005 aluminum alloy?

Status: aluminum and aluminum alloy cold rolled strip (0.8~1.3mm, H16, H26, H36)

What is the difference between 5005 aluminum alloy and 3003 alloy?

5005 aluminum alloy is similar to 3003 alloy, with medium strength and good corrosion resistance. 5005 aluminum alloy is used as conductor, cooker, instrument panel, shell and architectural decoration. The anodic oxide film is brighter and brighter than the oxide film on alloy 3003, and is consistent with the color of alloy 6063.

What is the purpose of 5000 aluminum alloy?

1.5005 is similar to 3003 alloy, with medium strength and good corrosion resistance. Used as conductor, cooker, instrument panel, shell and architectural decoration. The anodic oxide film is brighter than the oxide film on alloy 3003 and has the same hue as that of alloy 6063. The 5050 sheet can be used as the inner liner of refrigerator and refrigerator, automobile gas pipe, oil pipe and agricultural irrigation pipe; It can also process thick plate, pipe, bar, profile and wire, etc

2.5052 This alloy has good formability, corrosion resistance, plasticity, pipe and agricultural irrigation pipe; It can also process thick plate, pipe, bar, profile and wire. 5052 This alloy has good formability, corrosion resistance, plasticity, fatigue strength and medium static strength, and is used for manufacturing aircraft fuel tanks, oil pipes, and sheet metal parts of vehicles and ships, instruments, street lamp brackets and rivets, hardware products, etc

3.5056 magnesium alloy and cable sheath rivets, zippers, nails, etc; Aluminium-coated wire is widely used for processing agricultural insect catcher covers and other occasions requiring high corrosion resistance

4.5083 is used for occasions requiring high corrosion resistance, good weldability and medium strength, such as ship, automobile and aircraft plate weldments; Pressure vessels, refrigeration devices, television towers, drilling equipment, transportation equipment, and electrical equipment that require strict fire protection

Ammunition elements, armor, etc

5.5086 is used for occasions where high corrosion resistance, good weldability and medium strength are required, such as naval ships and automobiles; aircraft cryogenic equipment is drilled by the sight tower 5086 is used for occasions where high corrosion resistance, good weldability and medium strength are required, such as naval ships, automobiles, aircraft, low-temperature equipment, television towers, drilling units, transportation equipment, missile parts and decks, etc

6.5154 Welded structures, storage tanks, pressure vessels, ship structures and offshore facilities, transport tanks

7.5182 Thin plate is used for processing easy-open can cover, automobile body plate, control panel, reinforcement, bracket and other parts

8.5252 is used to manufacture decorative parts with high strength, such as decorative parts of automobiles. Bright and transparent oxide film after anodizing

9.5254 Hydrogen peroxide and other chemical product containers

10.5356 Aluminum magnesium alloy welding rod and wire with magnesium content greater than 3%

11.5454 Welded structures, pressure vessels, offshore facilities and pipelines

12.5086 is used for high corrosion resistance, good weldability and medium strength. Occasions, such as ships, cars, aircraft, cryogenic equipment, television towers, drilling equipment, transportation equipment, missile parts and decks, etc

13.5154 Welded structures, storage tanks, pressure vessels, ship structures and marine facilities, transport tanks

14.5182 sheet is used for processing easy-open can cover, automobile body plate, control panel, reinforcement, bracket and other parts

15.5252 is used to manufacture decorative parts with high strength, such as decorative parts of automobiles. Bright and transparent oxide film after anodizing

16.5254 Hydrogen peroxide and other chemical product containers

17.5356 Welding aluminum-magnesium alloy electrodes and wires with magnesium content greater than 3%

18.5454 Welded structures, pressure vessels, offshore facilities and pipelines

19.5A12 Welded structural parts, bulletproof deck.

From the above five series aluminum alloy grades and uses, we can see that the representative uses of 5000 series aluminum alloy and 5xxx aluminum alloy include aerospace fixture, electrical fixture, communication field, and are also widely used in automatic mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC plate solder carriers, etc., and also widely used in various industrial structural parts requiring certain strength and high corrosion resistance, such as manufacturing trucks, tower buildings Ships, trams and railway vehicles.