430 Stainless Steel Sheet/Plate

Solucky Steel is widely recognized as one of the finest 430 Stainless Steel Sheet/Plate manufacturers and suppliers in the industry. Their products are crafted with excellent precision, which results in a superior quality product, every time. They focus on customer satisfaction and prioritize customer feedback to constantly improve their products. Trusting Solucky Steel means investing in superior quality 430 Stainless Steel Sheet/Plate that not only upholds the highest standards of safety and longevity but also delivers the best value for your money. With this level of commitment, it’s no wonder Solucky Steel continues to be a leader in 430 stainless steel fabrication.

- Material Grade: 201/304/304l/316/316l/321/309s/310s/410/420/430/904l/2205/2507

- Type:Ferritic, Austenite, Martensite, Duplex

- Technology:Cold Rolled and Hot Rolled

- Size: According to the customer’s requests

- Standards: AISI ASTM JIS SUS DIN EN and GB

- Certifications: ISO 9001,SGS,BV

| Product Name | Stainless steel plate |

| Standard | ASTM,AISI,DINEN,GB,JIS |

| Material Grade | 201, 202 , 304 , 304L , 304H , 309, 309S , 310 , 310S ,316, 316L, 316Ti, 317, 317L, 321, 347, 347H , 409L , 420 , 420J1 , 420J2 , |

| 440A.440B.440C.904L.2205.2507.2520 ect. Or Customized | |

| Thickness | 0.4mm-3mm for cold rolled |

| 3mm-100mm for hot rolled or as your requirement | |

| Width | 1000mm/1219mm/1500mm for cold rolled |

| 1500mm/1800mm/2000mm for hot rolled or as your requirement | |

| Length | as your requirement |

| Surface | No.1,2B,No.4,BA,hairline,8K or as you need |

| Application | Steel sheet applies to construction field |

| Ships building industry | |

| Petroleum & chemical industries | |

| War and electricity industries | |

| Food processing and medical industry | |

| Boiler heat exchanger | |

| Machinery and hardware fields | |

| Packaging | Waterproof cloth packaging and on pallets, or according to customer requirements |

| Delivery | 7-15 days |

| Price Item | T/T,30% payment in advance,70% T/T after the copy of B/L or L/C at sight |

| Quality control | Mill Test Certificate is supplied with shipment |

| Export Country | USA,Southeast Asia,Mid East,Africa,Eastern Asia,Western Europe and so on |

| Chemical Properties of Frequently-used Stainless Steel Material Grade | |||||||||||

| UNS | ASTM | EN | JIS | C% | Mn% | P% | S% | Si% | Cr% | Ni% | Mo% |

| S20100 | 201 | 1.4372 | SUS201 | ≤0.15 | 5.5-7.5 | ≤0.06 | ≤0.03 | ≤1.00 | 16.0-18.0 | 3.5-5.5 | – |

| S20200 | 202 | 1.4373 | SUS202 | ≤0.15 | 7.5-10.0 | ≤0.06 | ≤0.03 | ≤1.00 | 17.0-19.0 | 4.0-6.0 | – |

| S30100 | 301 | 1.4319 | SUS301 | ≤0.15 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 16.0-18.0 | 6.0-8.0 | – |

| S30400 | 304 | 1.4301 | SUS304 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-10.5 | – |

| S30403 | 304L | 1.4306 | SUS304L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-12.0 | – |

| S30908 | 309S | 1.4833 | SUS309S | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 22.0-24.0 | 12.0-15.0 | – |

| S31008 | 310S | 1.4845 | SUS310S | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.50 | 24.0-26.0 | 19.0-22.0 | – |

| S31600 | 316 | 1.4401 | SUS316 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31603 | 316L | 1.4404 | SUS316L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

| S31703 | 317L | 1.4438 | SUS317L | ≤0.03 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

| S32100 | 321 | 1.4541 | SUS321 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-12.0 | – |

| S34700 | 347 | 1.455 | SUS347 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-13.0 | – |

| S40500 | 405 | 1.4002 | SUS405 | ≤0.08 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 11.5-14.5 | ≤0.60 | – |

| S40900 | 409 | 1.4512 | SUS409 | ≤0.08 | ≤1.00 | ≤0.045 | ≤0.03 | ≤1.00 | 10.5-11.75 | ≤0.50 | – |

| S43000 | 430 | 1.4016 | SUS430 | ≤0.12 | ≤1.00 | ≤0.040 | ≤0.03 | ≤0.75 | 16.0-18.0 | ≤0.60 | – |

| S43400 | 434 | 1.4113 | SUS434 | ≤0.12 | ≤1.00 | ≤0.040 | ≤0.03 | ≤1.00 | 16.0-18.0 | – | – |

| S44400 | 444 | 1.4521 | SUS444L | ≤0.025 | ≤1.00 | ≤0.045 | ≤0.03 | ≤1.00 | 17.5-19.5 | ≤1.00 | – |

| S40300 | 403 | – | SUS403 | ≤0.15 | 5.5-7.5 | ≤0.04 | ≤0.03 | ≤0.50 | 11.5-13.0 | ≤0.60 | – |

| S410000 | 410 | 1.40006 | SUS410 | ≤0.15 | ≤1.00 | ≤0.035 | ≤0.03 | ≤1.00 | 11.5-13.5 | ≤0.60 | ≤1.00 |

| S42000 | 420 | 1.4021 | SUS420J1 | 0.16~0.25 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 12.0-14.0 | ≤0.75 | ≤1.00 |

| S440A | 440A | 1.4028 | SUS440A | 0.60~0.75 | ≤1.00 | ≤0.04 | ≤0.03 | ≤1.00 | 16.0-18.0 | – | ≤0.75 |

| S32750 | SAD2507 | 1.441 | ≤0.03 | ≤1.2 | ≤0.035 | ≤0.02 | ≤0.80 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | |

| S31803 | SAF2205 | 1.4462 | ≤0.03 | ≤2.0 | ≤0.03 | ≤0.02 | ≤1.00 | 21.0-23.0 | 4.0-6.5 | 2.5-3.5 | |

| N08904 | 904L | 1.4539 | ≤0.0.3 | ≤2.0 | ≤0.035 | ≤0.03 | ≤1.00 | 18.0-20.0 | 23.0-25.0 | 3.0-4.0 | |

| Surface finish | Characteristics & Application |

| NO.1 | Hot-rolled surface,annealed and pickled,can be used as cold-rolling material,industial tanks and chem i cal devices. |

| NO.2D | Cold-rolled, an nealed and pick led with out skinpassing the dull products can be used as automobile parts, building materrials and pipings. |

| NO.2B | The surface brightness and flatness of NO.2B is better than NO.2D. Then through a special surfacetreament to improve its mechamical properties, N02B could nearly satisfy comprehensive uses. |

| NO.3 | Polished with abra sive belt of grit #100#120,have bet ter bright ness with discontinuous coarse stria, used as in ner and ex ter nal or na ments for building, electrical appliances and kitchen uten sils etc. |

| NO.4 | Polished with abrasive belt of grit #150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtud buildinginner and external ornaments electrical appliances, kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks, mainly used as building ornaments, elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin passed, the product has excellent brightness and good reflexivity like mirror, used for lectrical appliances, mirror, kitchen apparatus, or nament materials etc. |

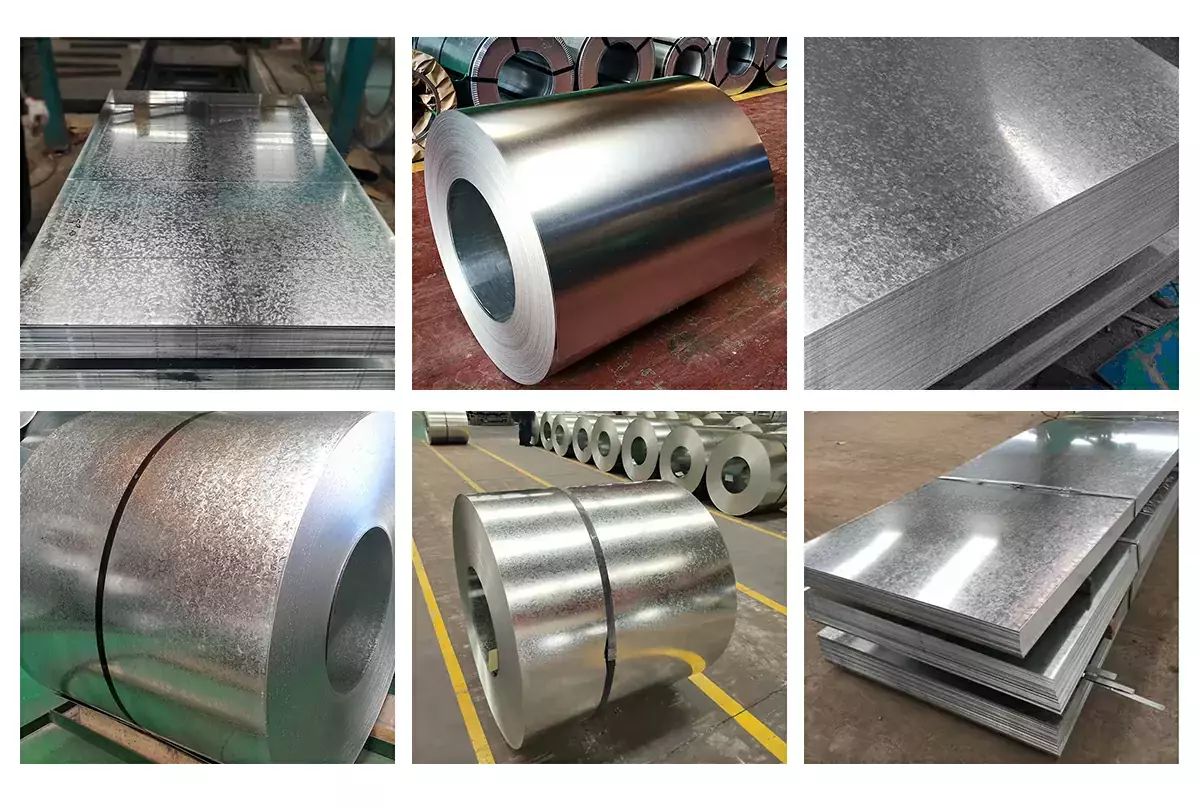

Steel Photos

Steel Packing

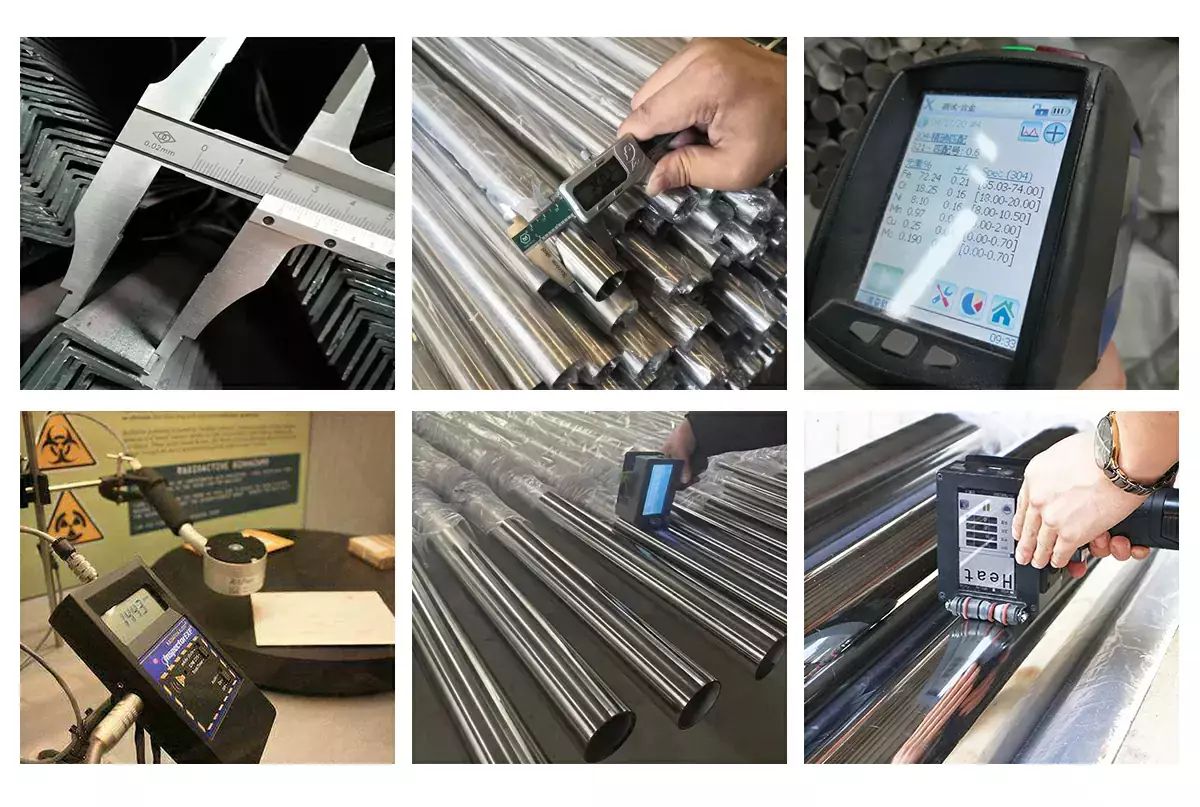

Quality Control