The meaning of HC380/590TR

The “HC” in HC380/590TR stands for “High Strength Cold Rolled”. The number “380” represents the minimum yield strength in megapascals (MPa) that the steel possesses, while “590” represents the minimum tensile strength in MPa. These values indicate the steel’s ability to resist deformation and withstand applied loads.

The “TR” in HC380/590TR stands for “Transformation Induced Plasticity”. TRIP (Transformation Induced Plasticity) steel refers to a type of advanced high-strength steel (AHSS) that exhibits a unique combination of high strength and excellent formability. TRIP steel undergoes a unique metallurgical transformation during deformation, where retained austenite within its microstructure transforms into hard martensite. This transformation provides increased strength and strain hardening capability while maintaining good formability.

Chemical composition and mechanical properties of HC380/590TR

Chemical composition of HC380/590TR

C(MAX): 0.23%

Mn(MAX): 2%

Si(MAX): 1.8%

Mechanical properties of HC380/590TR

YS(MPa): 380-480

TS(MPa): ≥590

EL(%) ≥28%

n ≥ 0.2

What is Transformation Induced Plasticity Steel TRIP?

Phase Transformation Induced Plasticity (TRIP) steel exhibits a specific microstructure consisting of ferrite, bainite, and retained austenite. This unique combination of phases contributes to the material’s exceptional mechanical properties. During the forming process, the retained austenite undergoes a transformation into martensite, which further enhances the plastic deformation ability of the steel. This transformation mechanism enables TRIP steel to achieve a balance between high strength and good formability, making it highly desirable for various applications.

The presence of ferrite, bainite, and retained austenite in TRIP steel provides distinct advantages. Ferrite is a relatively soft phase that contributes to the material’s ductility and formability. Bainite, on the other hand, is a harder phase that contributes to the overall strength of the steel. The retained austenite phase is particularly important in TRIP steel, as it undergoes a transformation into martensite under the influence of external forces or stresses.

The transformation of retained austenite into martensite during deformation is a key characteristic of TRIP steel. This transformation not only increases the overall strength of the material but also enhances its plasticity. The ability of the steel to undergo this transformation provides a mechanism for absorbing energy during deformation, leading to improved impact absorption properties.

TRIP steel is known for its high n value, which refers to the strain hardening exponent. The high n value indicates the steel’s ability to undergo significant strain hardening, allowing it to absorb energy and resist deformation under applied loads. This characteristic is essential for structural components subjected to dynamic loads, such as automotive parts in crash scenarios.

Additionally, TRIP steel exhibits excellent formability, which refers to its ability to be shaped or formed into complex geometries without fracturing or excessive strain localization. The presence of retained austenite and the transformation into martensite contribute to this formability by allowing the material to accommodate plastic deformation without premature failure.

What are the advantages of HC380/590TR?

HC380/590TR, as a specific grade of Transformation Induced Plasticity (TRIP) steel, offers several advantages:

1. High Strength: This high strength allows the material to withstand significant loads and provides structural integrity in various applications.

2. Enhanced Formability: TRIP steels, including HC380/590TR, possess excellent formability due to the presence of retained austenite and the transformation into martensite during deformation. This enables the steel to undergo significant plastic deformation without sacrificing its strength, making it suitable for complex shapes and deep drawing processes.

3. Improved Ductility: HC380/590TR exhibits good ductility, allowing it to elongate and deform without fracturing. This characteristic is essential for components subjected to bending, stretching, or other forming operations.

4. High Energy Absorption: The microstructure of HC380/590TR, which includes retained austenite, enables the material to absorb and dissipate energy during deformation. This property is beneficial in applications where impact resistance and crashworthiness are critical, such as automotive components.

5. Lightweight Design: TRIP steels, including HC380/590TR, provide an excellent strength-to-weight ratio. Their high strength allows for the design of lightweight structures without compromising performance, leading to fuel efficiency improvements in automotive and transportation industries.

6. Good Fatigue Resistance: HC380/590TR exhibits good fatigue resistance, enabling it to withstand repeated loading cycles without experiencing premature failure. This characteristic is essential for components subjected to cyclic or dynamic loading, such as suspension parts or components in rotating machinery.

Application of HC380/590TR

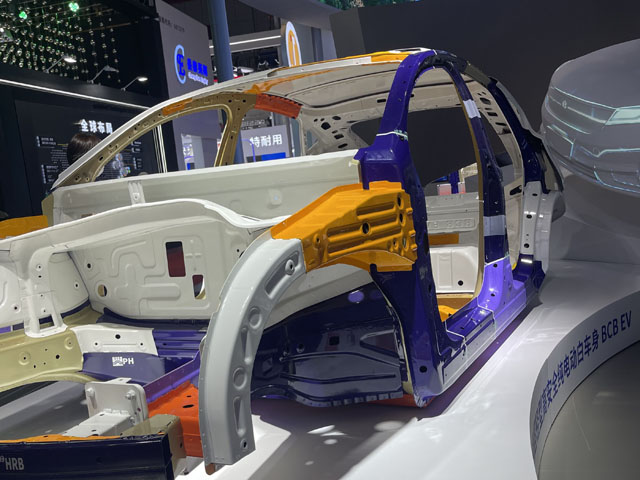

HC380/590TR, a grade of Transformation Induced Plasticity (TRIP) steel, finds wide application across various industries due to its unique combination of high strength, excellent formability, and energy absorption properties. The material’s high strength makes it ideal for applications requiring structural integrity and load-bearing capabilities. HC380/590TR’s enhanced formability allows it to be shaped into complex geometries and undergo deep drawing processes without sacrificing its strength. Moreover, its ability to absorb and dissipate energy during deformation ensures exceptional impact resistance, making it well-suited for automotive components such as crash structures, safety reinforcements, and impact-absorbing members. Additionally, HC380/590TR’s lightweight design contributes to fuel efficiency improvements in transportation applications. Its fatigue resistance and cost-effectiveness further extend its utility to sectors such as construction, machinery, and industrial equipment.