hot rolled coil steel type application|hot-rolled coil steel

hot rolled coil steel type application|hot-rolled coil steel-The straight hair coil is processed by cutting head, tail cutting, edge trimming and multi-pass straightening, leveling and other finishing lines, and then cutting or re-rolling, that is, hot-rolled steel, flat hot-rolled steel coil, slitting Belt and other products.

1. Structural steel

Mainly used in the production of steel structure parts, bridges, ships and vehicles.

2. Weathering steel

Add special elements (P, Cu, C, etc.), with good corrosion resistance and atmospheric corrosion resistance, used in the production of containers, special vehicles, and also used in building structures.

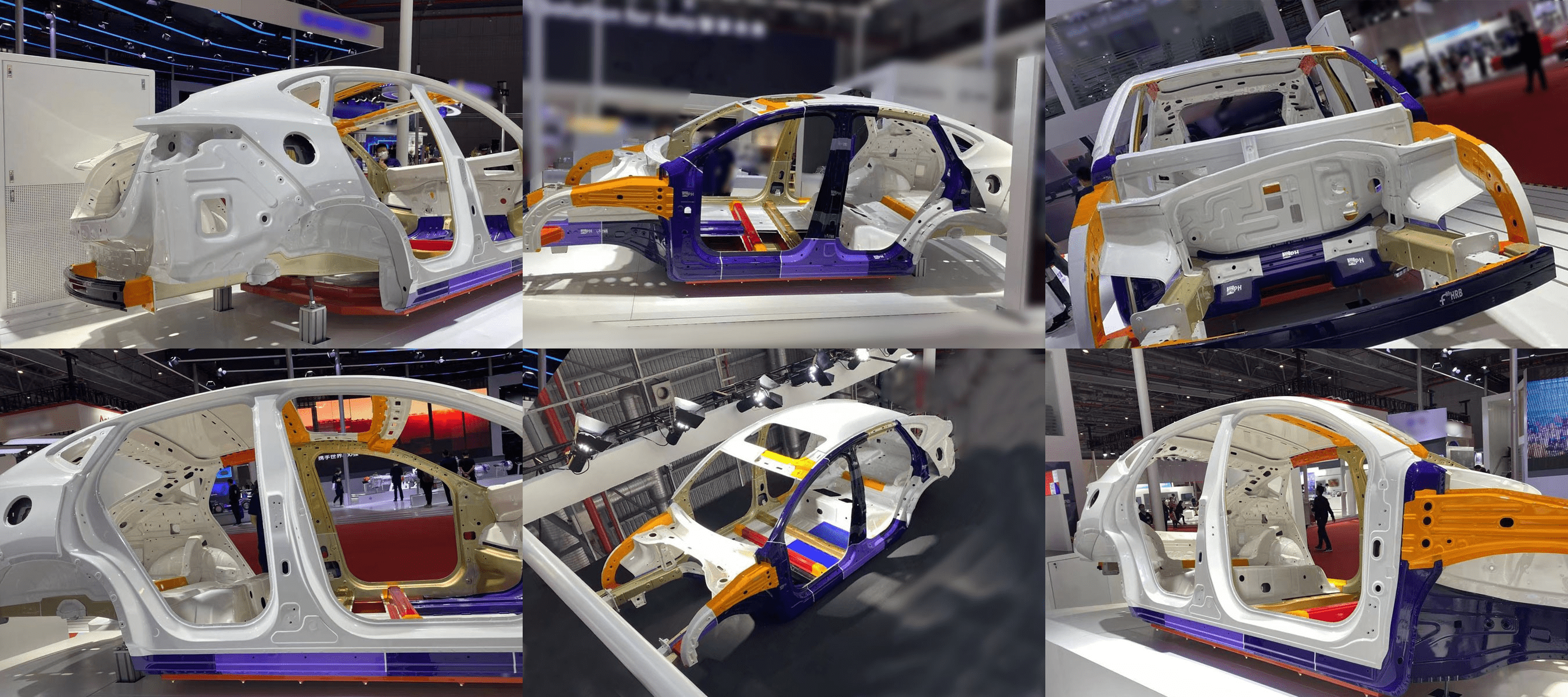

3. Steel for automobile structure

High-strength steel plate with good stamping performance and welding performance, used in the production of automobile FRAME, WHEEL, etc.

4. Hot-rolled special steel

Carbon steel, alloy steel and tool steel for general mechanical structures are used in the production of various mechanical parts after heat treatment.

5. Cold rolled original plate

It is used to produce various cold rolled products, including CR, GI, color-coated sheet, etc.

6. Steel plate for steel pipe

With good processing performance and compressive strength, it is used to produce high-pressure gas pressure vessels filled with LPG, acetylene gas and various gases with an inner volume of less than 500L.

7. Steel plates for high pressure vessels

With good processing performance and compressive strength, it is used to produce high-pressure gas pressure vessels filled with LPG, acetylene gas and various gases with an inner volume of less than 500L.

8. Stainless steel plate

Stainless steel has good corrosion resistance and is mainly used in the food industry, surgical equipment, aerospace, petroleum, chemical and other industries.

Cold-rolled sheet has high hardness and is relatively difficult to process, but it is not easy to deform and has high strength.

Hot-rolled steel has relatively low strength and poor surface quality (with oxidation and low finish), but has good plasticity, generally medium and thick plates, and cold-rolled plates: high strength, high hardness, and high surface finish, generally thin plates, which can be used as stamping Use board.

Hot-rolled steel, the mechanical properties are far inferior to cold working, and inferior to forging, but have better toughness and ductility.

Cold-rolled steel has a certain degree of work hardening and low toughness, but it can achieve a good yield-to-strength ratio and is used to cold-form parts such as spring sheets. At the same time, because the yield point is closer to the tensile strength, there is no danger during use. Predictability, accidents are prone to occur when the load exceeds the allowable load.

Related Reading: