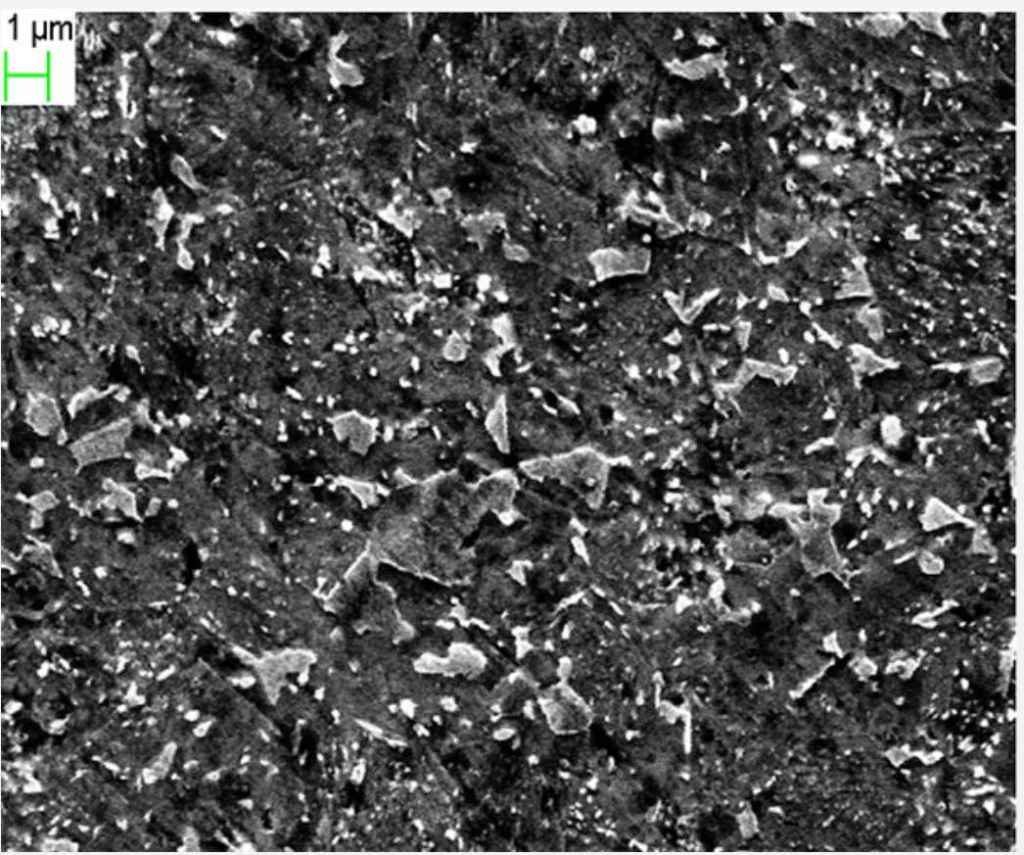

The microstructure of the high-plasticity multiphase steel is dominated by a bainite matrix, and a fine and uniform microstructure is obtained by adjusting the precipitation of submicron carbides. Compared with traditional multiphase steel, it has higher plasticity (fracture Yanber ratio), and also maintains better bending, flanging and hole expansion properties. It is mainly used in structural parts such as door sills and seat slide rails. is an advanced high-strength steel designed to combine high strength with excellent formability.

Is CR1000/1370CH a high plasticity composite phase steel?

Yes, CR1000/1370CH is a high ductility multiphase steel designed to combine high strength with excellent formability, produced using a process known as Quenching and Partitioning (Q&P). The “CR” in this steel’s name stands for “Cold-Rolled,” meaning it was rolled at room temperature. The number “1000/1370” refers to the minimum tensile strength of steel, the yield strength is 1000 MPa, and the ultimate tensile strength is 1370 MPa.

To sum up, CR1000/1370CH does not specifically refer to high-plastic composite phase steel, but an ultra-high-strength steel that has certain similarities with HPCP steel in terms of production process and performance combination.

What are the characteristics of CR1000/1370CH steel?

CR1000/1370CH steel is an ultra-high strength steel designed to provide a combination of high strength and excellent formability. Some of the main properties of this steel include:

High Strength: CR1000/1370CH steel has a minimum yield strength of 1000 MPa and a minimum ultimate tensile strength of 1370 MPa, making it one of the strongest steels available.

Excellent Formability: Despite its high strength, CR1000/1370CH steel is also highly formable, meaning it can be easily formed into complex parts without cracks or other defects. This is due to its unique microstructure, consisting of hard and soft phases.

Good Ductility: CR1000/1370CH steel also has good ductility, which means it can deform plastically without breaking or cracking. This is an important property for many applications as it allows the steel to absorb energy and withstand impact without failure.

Enhanced Corrosion Resistance: CR1000/1370CH steel has enhanced corrosion resistance due to the addition of certain alloying elements, which help protect the steel from rust and other forms of corrosion.

Cold-rolled surface finish: CR1000/1370CH steel has a smooth and uniform surface finish due to the cold-rolled process used in the production process. This makes it ideal for use in applications requiring a high quality surface finish.

What is the chemical composition of CR1000/1370CH steel?

The chemical composition of CR1000/1370CH steel varies by specific manufacturing process and producer. But in general, it is an alloy steel that contains the following elements:

Carbon (C): 0.15% to 0.25%, the carbon content contributes to the strength and hardness of steel.

Manganese (Mn): 1.0% to 2.0%.

Silicon (Si): 0.5%, silicon is added to steel to improve its strength and wear resistance.

Phosphorus (P): 0.03%. Phosphorus is an impurity, which is generally controlled at a low level in steel.

Sulfur (S): ≦ 0.02%

Chromium (Cr):≦1.0%.

Other elements: In addition to the elements listed above, CR1000/1370CH steel may also contain a small amount of other elements, such as nickel (Ni), copper (Cu), molybdenum (Mo), etc., depending on the specific application requirements.

How about the mechanical properties of CR1000/1370CH?

CR1000/1370CH is a high strength steel designed to combine high strength with excellent formability. The mechanical properties of CR1000/1370CH steel may vary depending on the specific manufacturing process and producer. In general, however, some of the key mechanical properties of this class of steel include:

Yield strength: The minimum yield strength of CR1000/1370CH steel is usually around 1000 MPa.

Ultimate tensile strength: The minimum ultimate tensile strength of CR1000/1370CH steel is usually around 1370 MPa.

Elongation: CR1000/1370CH steel typically has an elongation in the range of 10% to 15%, which means it can deform plastically without breaking or cracking.

Hardness: CR1000/1370CH steel is a relatively hard material, with a typical hardness of about 300-400HV.

Fatigue Strength: CR1000/1370CH steel has excellent fatigue strength, meaning it can withstand repeated stress cycles without failure.

What are the heat treatment methods of CR1000/1370CH steel?

CR1000/1370CH steel can be heat treated to obtain different combinations of strength, ductility and toughness. The most common heat treatment methods for CR1000/1370CH steel include:

Quenching and Tempering: This heat treatment involves heating the steel to a high temperature and then quenching it in a cooling medium such as oil or water. This rapid cooling process “freezes” the microstructure of the steel, creating a structure that is hard, brittle and prone to cracking. To increase the ductility and toughness of the steel, it is then tempered by heating it to a lower temperature and holding it at that temperature for a period of time. The process reduces the hardness of the steel while increasing its ductility and toughness.

Annealing: This heat treatment involves heating steel to high temperatures and then allowing it to cool slowly in a controlled environment. This process reduces the steel’s hardness and increases its ductility and toughness. Annealing is commonly used to soften steel and make it easier to form.

Normalizing: This heat treatment is similar to annealing, but the steel is cooled in air rather than in a controlled environment. This process reduces the steel’s hardness and increases its ductility and toughness.

Precipitation Hardening: This heat treatment involves heating the steel to high temperatures followed by rapid cooling to room temperature. This produces a supersaturated solid solution of the steel alloying elements. The steel is then aged at lower temperatures, causing the alloying elements to precipitate out of solution, forming small, hard particles. This process increases the hardness and strength of the steel while maintaining its ductility and toughness.

How does CR1000/1370CH perform welding?

CR1000/1370CH steel can be welded using common arc welding techniques such as gas metal arc welding (GMAW) and gas tungsten arc welding (GTAW). However, due to its high strength and high carbon content, special care must be taken during welding to avoid problems such as cracking and reduced toughness in the heat-affected zone (HAZ). Some important considerations for welding CR1000/1370CH steel include:

Preheating: Preheating the steel prior to welding helps reduce the thermal gradient between the weld and the parent metal, thereby minimizing the risk of cracking. Preheating temperature and time should be selected according to steel thickness and welding conditions.

Welding process: Both GMAW and GTAW are suitable for welding CR1000/1370CH steel, but the welding process should be selected according to the specific application and welding conditions. In general, low heat input and slow cooling rates are preferred to minimize the risk of cracking and maintain good toughness.

Post Weld Heat Treatment: Post weld heat treatment (PWHT) can be used to relieve residual stress and improve the toughness of the HAZ. Specific PWHT parameters should be selected according to steel composition, welding conditions and desired properties.

Is the hardness of CR1000/1370CH suitable for machining?

The high hardness of CR1000/1370CH steel makes machining a challenging process. However, with proper tooling and machining techniques, good results can be obtained.

The high hardness of CR1000/1370CH steel is mainly due to its high strength and composite microstructure. While this hardness provides excellent wear and abrasion resistance, it can also make machining more difficult. Hard phases in the microstructure can cause rapid tool wear, affecting the surface finish and dimensional accuracy of machined parts.

To overcome these challenges, it is important to use appropriate tool materials, coatings and processing parameters. It is generally recommended to use carbide or ceramic tool materials for machining CR1000/1370CH steel, because these materials are more wear-resistant than traditional high-speed steel tools. In addition, coatings such as diamond-like carbon (DLC) can provide further protection against wear.

In terms of machining parameters, it is important to use the proper cutting speed, feed and depth of cut to avoid excessive tool wear and maintain good surface finish and dimensional accuracy. In general, slower cutting speeds and lighter feeds are recommended when machining CR1000/1370CH steel, as this reduces heat generation during machining and helps minimize tool wear.

Overall, while the high hardness of CR1000/1370CH steel can make machining more challenging, good results can still be achieved with proper tooling, coating and machining parameters. It is important to work with an experienced machinist and follow recommended machining procedures to ensure high quality parts.

What are the applications of CR1000/1370CH steel in automobiles?

CR1000/1370CH steel is a high strength steel commonly used in automotive applications where strength, weight reduction and crashworthiness are key factors. Some common applications of CR1000/1370CH steel in automobiles include:

Body Structure: CR1000/1370CH steel can be used to manufacture lightweight, high-strength body structures that meet stringent safety and performance requirements. The steel’s high strength and composite microstructure make it ideal for use in areas requiring high stiffness and energy absorption, such as door beams, roof rails and pillars.

Chassis Components: CR1000/1370CH steel can be used to manufacture high-strength, lightweight chassis components that improve handling, stability and ride quality. Examples include suspension components, steering components and subframes.

Crash Management Systems: CR1000/1370CH steel can be used to create advanced crash management systems that provide a high level of protection for vehicle occupants in the event of a crash. The steel’s high strength and energy-absorbing properties make it ideal for use in areas such as bumper systems, front-end modules and side impact beams.

Exhaust System: CR1000/1370CH steel can be used to create a lightweight, high strength exhaust system for improved performance and reduced emissions. The high temperature and corrosion resistance of this steel make it ideal for use in exhaust components such as manifolds, pipes and catalytic converters.

Overall, CR1000/1370CH steel is a versatile material that offers a range of advantages for automotive applications. Its high strength, light weight and crashworthiness make it ideal for a wide variety of structural and nonstructural automotive components.