The NI3 Double Stacked Self-Locking Washer is an embedded electronic component commonly used on circuit boards. Its main function is to provide mechanical support and electrical connection to ensure reliable connection between components on the circuit board. NI3 double stack self-locking washers consist of more than two metal sheet layers which are elastically deformable to a certain extent. When they are compressed, they expand outward, creating a firm contact between the pin and the board. In addition, NI3 double-stack self-locking washers also have a self-locking function, which can prevent pins from falling off under conditions such as vibration or shock.

How does the NI3 double stack self-locking washer work?

The working principle of NI3 double-stack self-locking washers is based on its special structural design. It consists of two or more metal sheets that are elastically deformable to a certain extent. When the NI3 Dual Stack Locking Washers are compressed, they expand outward and grab the pins and form a secure contact. When the connection between the pin and the circuit board is subject to vibration or shock, the internal structure of the NI3 double-stack self-locking washer will make it grip the pin more tightly, thereby preventing the pin from falling off. In addition, NI3 double-stack self-locking washers also have good electrical conductivity, which can ensure a stable electrical connection between the pin and the circuit board.

Which screw type is suitable for NI3 double stack self-locking washers?

NI3 double-stack self-locking washers can be applied to various screw types, such as M2, M2.5, NI3, etc. When selecting an NI3 double-stack self-locking washer, it is necessary to consider whether its size and thickness match the screw used, and ensure that it can provide sufficient support force and electrical connection performance. In addition, it is also necessary to select appropriate materials and surface treatment methods according to specific application scenarios to meet different requirements, such as anti-corrosion and high temperature resistance.

What are the materials of NI3 type double stacked self-locking washers?

NI3 type double-stack self-locking washers can be manufactured in a variety of materials to suit different application environments and requirements. The following are common materials of NI3 type double stack self-locking washers:

Stainless steel: stainless steel AISI 316L EN10088-14404, surface hardness ≥550HV0.05 after case hardening

Carbon Steel: Hardness 465-550HV10 hardened and annealed

Other materials can be based on customer needs (hydrochloride-resistant nickel-based alloy C-276, etc..)

What are the surface treatment methods for NI3 type double stacked self-locking washers?

The surface treatment methods of NI3 type double stacked self-locking washers are mainly as follows:

- KL100+VH301 has no Cr6, and the red corrosion resistance is at least 600 hours (salt spray corrosion test according to ISO9227)

- Mechanical galvanizing + sealing without Cr6, red corrosion resistance at least 600 hours (salt spray corrosion test according to ISO9227)

- Other surface treatment according to the minimum order quantity

It is necessary to choose a suitable surface treatment method according to the specific application environment and use requirements to manufacture NI3 type double stacked self-locking washers. At the same time, care should be taken to protect the surface of the connector during use to avoid affecting the performance and life of the connector due to surface damage.

What are the performance characteristics of NI3 double stack self-locking washers?

Performance features of the NI3 double stack self-locking washers include:

Self-locking function: When the connection between the pin and the circuit board generates vibration or shock, the internal structure of the NI3 double-stack self-locking washer will make it grip the pin more tightly to prevent the pin from falling off.

Good electrical conductivity: NI3 double-stack self-locking washers have good electrical conductivity, which can ensure a stable electrical connection between the pins and the circuit board.

High reliability: The structural design of the NI3 double-stack self-locking washer enables it to maintain a good connection state even in harsh environments such as vibration and shock, thereby improving its reliability in use.

EASY INSTALLATION: Installation of the NI3 Dual Stack Self-Locking Washer is as simple as placing it on the pin and compressing lightly.

Wide application: NI3 double-stack self-locking washers are usually suitable for various electronic devices, such as mobile phones, tablet computers, computer motherboards, etc., and have a wide range of application prospects.

How are NI3 double stacked self-locking washers manufactured?

NI3 double-stack self-locking washers are manufactured through a series of complex manufacturing processes. The following is its general manufacturing process:

Material preparation: Cut the required metal materials (such as copper, stainless steel, etc.) into specified sizes and shapes.

Stamping: A punch is used to process sheet metal into a gasket with a specific geometry.

Surface treatment: Surface spraying or electroplating treatment of the gasket to improve its oxidation resistance and electrical conductivity.

Lamination: Stacking two or more metal sheets together and using special tools to hold them together.

Compression molding: Place stacked metal sheets in a specific mold, and then apply appropriate pressure to deform it into a prescribed shape and size.

Cleaning and inspection: Clean the manufactured NI3 double-stacked self-locking washers, and check their appearance and size to ensure that they meet the requirements.

Packing: Pack the manufactured NI3 double-stacked self-locking washers, mark and record the quality, and finally deliver them to the customer.

It should be noted that the manufacturing process of NI3 double-stacked self-locking washers needs to go through multiple processes, and each link needs to be strictly controlled to ensure that its performance and reliability meet customer requirements.

How to install and use NI3 double-stack self-locking washers?

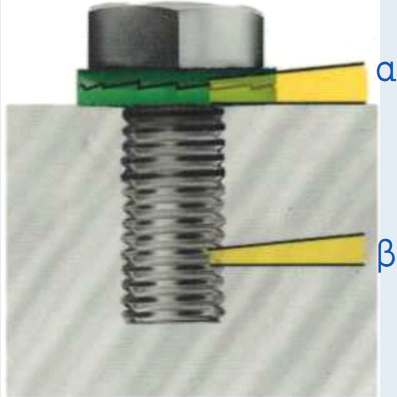

The installation of double-stack self-locking washers is very simple, just put the inner helical tooth surfaces of the two washers against each other and place them between the nut and the connecting material. The radial relief on the outside of the nut will be connected with the metal material. When the nut is tightened, the outer radial embossed surface of the double-stacked self-locking washer is engaged with the contact surfaces at both ends, and the slope angle of the helical tooth surface on the inner side of the washer is greater than the angle of the bolt thread.

What is the purpose of the NI3 double stack self-locking washer?

NI3 double-stack self-locking washers are usually used in various electronic devices, such as mobile phones, tablets, computer motherboards, etc., as an important connection element. Its main uses include:

Electrical connection: NI3 double-stack self-locking washers can provide good electrical conductivity and stable electrical connection to ensure reliable connection between components on the circuit board.

Mechanical support: The special structure of NI3 double-stacked self-locking washers can provide mechanical support to prevent components from loosening or falling off under conditions such as vibration or impact.

Reliability: NI3 double-stack self-locking washers have good durability and reliability, and can maintain a good connection state under various harsh environments.

Simplicity: NI3 double-stack self-locking washers are easy to use and fast to install, which can greatly shorten the assembly time of components.

In conclusion, NI3 double-stack self-locking washer is an important connection element widely used in electronic equipment, and its excellent performance and reliability make it an indispensable part in circuit design.