The microstructure of hot-rolled steel sheets for stamping consists of a ferrite matrix dispersed with carbides. The morphology and size of carbides are determined by the chemical composition of the steel and the cooling rate. The microstructure is usually homogeneous but may contain small areas of segregation.

What is the chemical composition of SPHE steel plate?

In general, SHPD chemical elements will be based on the following criteria:

brand

| C(Carbon) | Si(Silicon) | Mn(Manganese) | P(Phosphorus) | S(Sulfur) | Al(Aluminum) |

SPHE | ≤0.10 | ≤0.05 | ≤0.50 | ≤0.030 | ≤0.035 | ≥0.010 |

These chemical elements are the main components to form SPHE steel. It can be seen from the above table that there is a certain range, not specific data, because different manufacturers will mix them according to different needs. For example, some manufacturers only mix in 0.35% manganese and 0.025% phosphorus, etc.

What are the mechanical properties of SPHE steel plates?

Yield strength: ≧210MPa

Tensile strength: 270-400MPA

Post-break derivation rate: ≧39%

SPHE has good mechanical properties as a hot-rolled steel sheet for deep drawing. They are durable and can withstand high temperatures. They are also easily formed and made into stamped parts.

What is the forming process of SPHE steel plate?

Hot-rolled steel sheets are made from raw materials heated above their recrystallization temperature. This makes them easier to work with and results in the finished product being less likely to be damaged during shipping or handling.

SPHE hot-rolled steel plates are produced using a process known as Thermo-Mechanical Controlled Processing (TMCP). This involves heating the raw material above its recrystallization temperature, followed by rapid cooling. TMCP produces finished products with better mechanical properties than those simply cooled from the hot-rolled state.

The properties of SPHE hot rolled steel plates make them suitable for a wide range of applications. It’s durable, yet easy to use. It can be used in everything from construction to transportation, and its versatility makes it a popular choice for many businesses.

What are the points to pay attention to in the production process of SPHE steel plate?

Stamping operations are performed on hot-rolled steel sheets to give desired shapes and features. Hot-rolled steel sheets for stamping are made by passing steel through rolls at high temperatures. This process endows the steel plate with the following properties:

- Improve ductility: The hot rolling process endows the steel plate with higher ductility, which helps to achieve better stamping effect.

- Enhanced formability: The high temperature obtained during hot rolling helps to enhance the formability of the steel sheet. This is useful when creating complex stamped shapes.

- Improve the surface finish: the surface of the hot-rolled steel plate is clean and smooth, which is conducive to obtaining a good stamping effect.

What is the surface treatment method of SPHE steel plate?

Hot-rolled steel sheets can be divided into pickling surface and non-pickling surface according to the surface treatment method. Pickling refers to the use of hydrochloric acid to remove the scale on the hot-rolled plate to obtain a beautiful and smooth surface. Pickling improves the surface quality for welding, oiling and painting.

What is the surface quality grade of SPHE steel plate?

The surface quality grades that SPHE hot-rolled pickled plates can provide are:

*Normal Surface FA

*Higher surface FB

What are the product categories of SPHE steel plates?

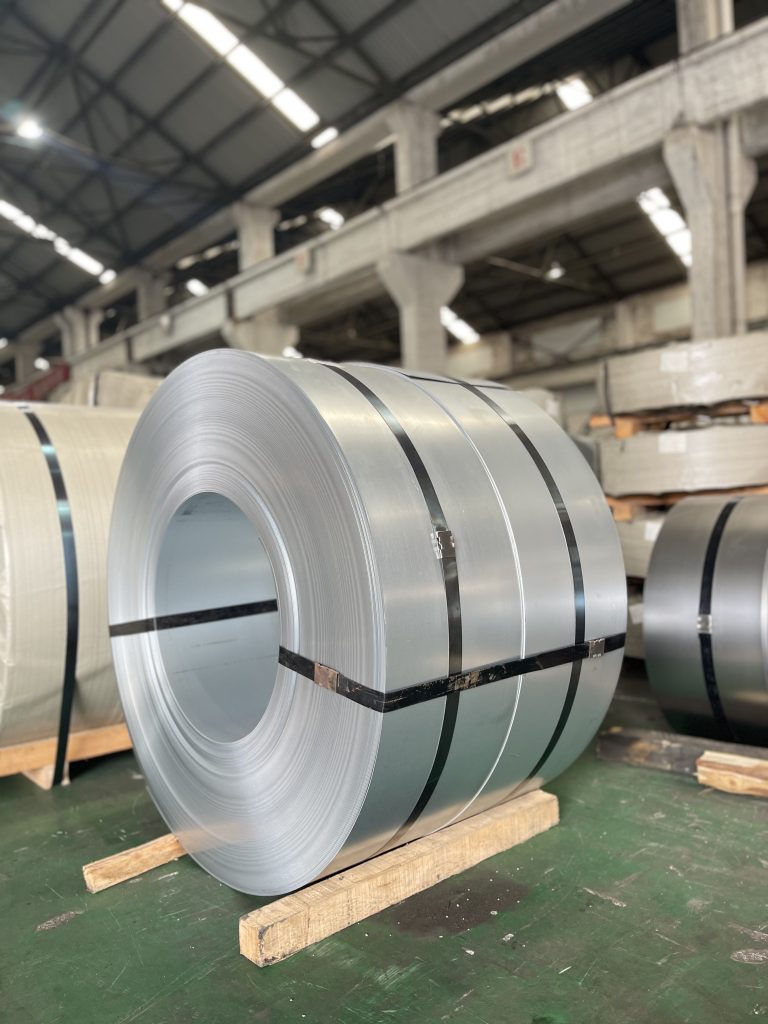

SPHE hot-rolled pickled plate can provide the following three types of steel plate (steel strip):

*Hot rolled steel strip

*Hot rolled steel plate

*Hot rolled slitting steel strip

What are the main characteristics of SPHE hot rolled steel sheets?

SPHE hot-rolled steel plate has good stamping performance, smooth surface and excellent weldability. With these advantages, it is widely used in automobile manufacturing, home appliance manufacturing, container manufacturing and other industries.

The main features of SPHE hot-rolled steel plates are as follows:

- Good stamping performance: the material is easy to press and form, with low yield point and high elongation.

- Smooth surface: The surface of SPHE hot-rolled steel plate is smooth and free of scale, with good surface roughness.

- Excellent weldability: the material has good weldability, and can be welded safely and reliably by conventional methods.

Good toughness: The material has good toughness and can withstand shock and vibration without damage.

What are the application fields of SPHE hot rolled steel plate?

SPHE hot-rolled steel sheets are excellent materials for a variety of applications due to their unique properties. Some of the most common application areas for SPHE hot rolled steel sheets include:

-Automobile industry

-Achitechive

-Appliance industry

-Machinery Industry

SPHE hot-rolled steel sheets are especially suitable for the automotive and construction industries due to their high strength and durability. In addition, the unique surface finish of SPHE hot-rolled steel sheets makes them aesthetically pleasing and ideal for use in appliances and machinery.

What are the advantages of SPHE hot rolled steel plate?

SPHE hot rolled steel plate has many advantages. First of all, it has a good visual effect due to its high surface quality. Second, it is easy to process and weld. Third, it has high strength and toughness, making it suitable for a variety of applications. Finally, it is also environmentally friendly as it can be recycled. Another point is that SPHE deep-drawing hot-rolled steel sheets are produced by a process of rolling steel at a temperature higher than its recrystallization temperature while maintaining its austenitic structure. This makes it possible to obtain ductile materials with high strength-to-density ratios. The main advantages of this steel are wear resistance and high temperature resistance.