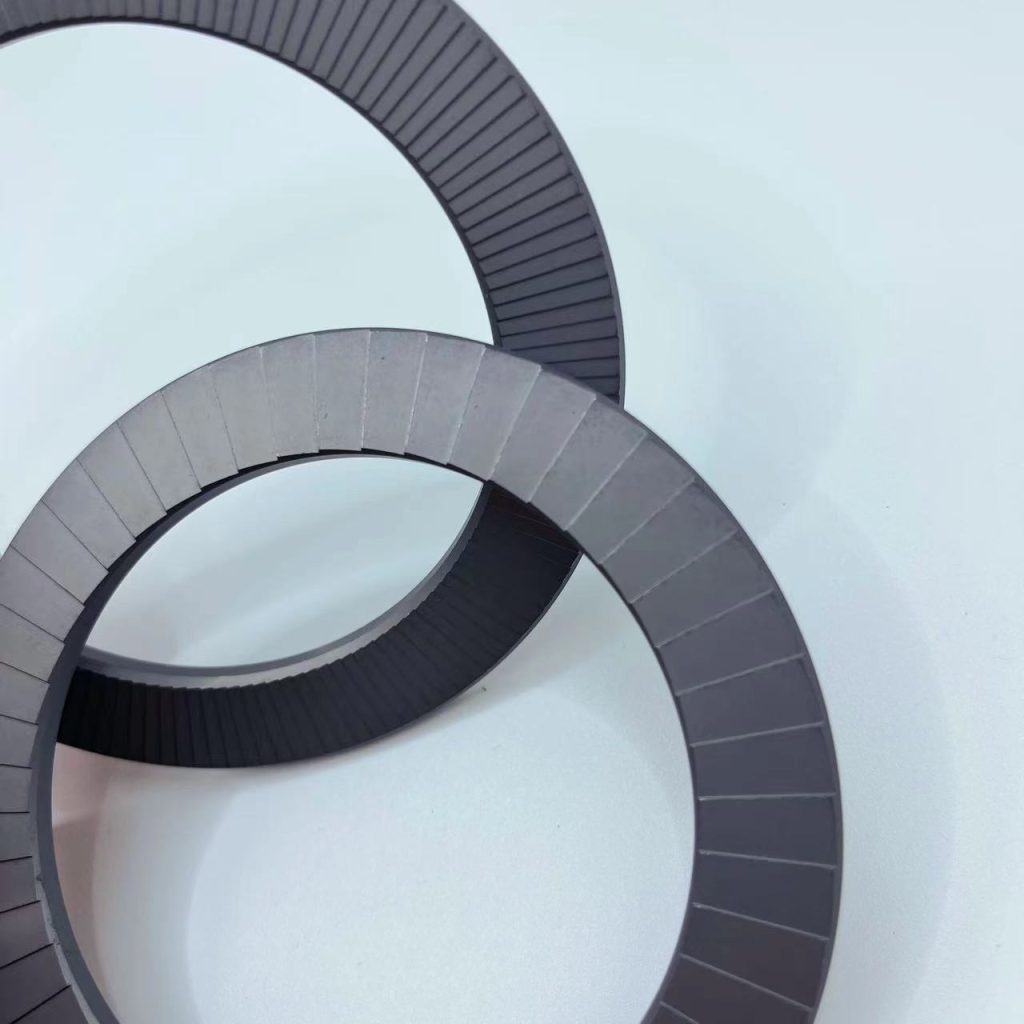

NL6 double stack self-locking washer is a special kind of washer, which is usually used to provide an extra safety function when fastening bolts or screws. It consists of two separate gaskets, one inner and one outer, which snap into each other with special flanges. When a bolt or screw is tightened, the inner washers of the NL6 Dual Stack Self-Locking Washers compress outward while the outer washers contract inward, creating a tight nested structure.

What are the dimensions and specifications of NL6 double-stack self-locking washers?

NL6 double stack self-locking washer is a kind of elastic washer, usually used to prevent thread loosening. Dimensions may vary by manufacturer, but the gasket is usually made of metal or plastic and has a ring shape.

How does the NL6 double stack self-locking washer perform?

NL6 Double Laminated Locking Washer is a high quality fastener material with excellent properties and features:

Self-locking performance: NL6 double-stacked self-locking washers are designed with a double elastic structure, which can provide strong self-locking force when tightening, making the connection more firm and stable.

Shock and noise reduction: NL6 double-stacked self-locking washers have excellent shock and noise reduction effects, which can effectively reduce the vibration and noise generated by machinery and equipment during operation.

Abrasion Resistant and Corrosion Resistant: Due to the manufacture of high-quality materials, NL6 double stacked self-locking washers have excellent wear resistance and corrosion resistance, and can be used for a long time without damage.

Good sealing: NL6 double-stacked self-locking gasket has excellent sealing performance, which can effectively prevent liquid or gas leakage and ensure the normal operation of the equipment.

High stability: NL6 double-stacked self-locking washers have stable performance and can maintain good fastening effects in various environments to ensure the stability of machinery and equipment.

What is the material of the NL6 double stack self-locking washer?

Normally, the material of NL6 double stack self-locking washers can be metal or plastic. Metal materials generally include stainless steel, aluminum, copper, titanium, and the like. These materials have high strength, corrosion resistance and wear resistance, and are suitable for use in environments requiring heavy loads or high and low temperatures. Plastic materials usually include nylon, polyamide, polyethylene, etc. They are lightweight, have low short-term water absorption, and good insulation performance, but relatively low strength, so they are usually used in some light-load or low-load environments. The choice of material should be determined according to actual needs and application scenarios.

What is the installation method of NL6 double-stack self-locking washers?

NL6 double-stack self-locking washer is a kind of sealing element commonly used in the connection of bolts and nuts. It has the characteristics of firm self-locking and good sealing performance. The following is the installation method of NL6 double-stack self-locking washers:

- Place the NL6 double stack self-locking washer correctly on the nut or bolt. Pay attention to choose the appropriate model and specification.

- Use a wrench or torque wrench to turn the bolt or nut clockwise until the required tightening torque is reached.

- Check whether the NL6 double-stack self-locking washers are installed correctly, and confirm whether the bolts or nuts have been tightened in place.

It should be noted that during the installation process, it is necessary to ensure that both rings of the NL6 double-stack self-locking washer can fully fit the surface of the nut or bolt to ensure its normal operation. In addition, for working conditions such as high temperature, high pressure and special media, NL6 double-stack self-locking washers of corresponding materials and models should also be selected to ensure their reliability and safety.

What are the characteristics of NL6 double-stack self-locking washers?

NL6 double stack self-locking gasket is a sealing element with the following characteristics:

Good self-locking performance: NL6 double-stack self-locking washer adopts double-layer spring structure, which can effectively prevent nuts or bolts from loosening due to external forces such as vibration.

Good sealing: There is an O-shaped rubber sealing ring between the two rings of the NL6 double-stacked self-locking gasket, which can improve the sealing performance and avoid the leakage of liquid, gas and other media.

Wide range of applications: NL6 double stacked self-locking washers can be used in various working environments, including high temperature, high pressure and corrosive media.

EASY INSTALLATION: The NL6 Double Stack Self Locking Washer is easy to install, just place it properly on the nut or bolt. At the same time, no special tools are required for installation.

What are the uses of NL6 double-stack self-locking washers?

NL6 double stack self-locking washer is a sealing element commonly used in bolt and nut joints, widely used in various fields. Main uses include:

Mechanical equipment: The use of NL6 double-stack self-locking washers in mechanical equipment can increase the fastening strength of bolts and nuts, and avoid loosening of the connection parts due to vibration and other reasons.

Automobile manufacturing: In automobile manufacturing, NL6 double-stacked self-locking washers are widely used in the joints of engines, transmissions, tires and other components.

Aerospace: Because NL6 double-stacked self-locking washers have good self-locking properties, high temperature resistance, and corrosion resistance, they are also widely used in the aerospace field.

Petrochemical industry: The petrochemical industry usually needs to deal with various media, and NL6 double-stacked self-locking gasket has excellent sealing performance, so it is also widely used in the connection of pipelines, containers and other equipment.

What are the problems that may occur in the use of NL6 double stacked self-locking washers?

NL6 double stacked self-locking washer is a commonly used fastener material, mainly used to connect or fix different parts. During use, the following problems may occur:

Looseness: If the gasket is too loose, it cannot provide enough fastening force, causing the connection to loosen or even fall off.

Too tight: If the gasket is too tight, it will cause deformation or damage to the connecting parts, which will affect the normal operation of the machine.

Abrasion: After long-term use, the gasket may experience wear, deformation, etc., resulting in a decrease in fastening force.

Leakage: If the seal of the gasket is not good, it will cause liquid or gas leakage, which will affect the use effect of the equipment.

Corrosion: Gaskets used in wet or corrosive environments may exhibit corrosion, reducing their service life.

Contact us

Our company is a professional manufacturer of fastener materials with many years of experience. We have advanced production equipment and technology, which can guarantee the quality and stability of our products. Manufactured with high-quality materials, our NL6 double-stack self-locking washers have excellent wear resistance, corrosion resistance, sealing and stability, and are suitable for fastener connections of various machinery and equipment.

At the same time, our company pays attention to customer experience and provides personalized services for each customer, including technical support, pre-sales consultation, after-sales service, etc., so that you can be more convenient, at ease and at ease during use.

If you need to buy NL6 double-stack self-locking washers now, please feel free to contact our customer service staff, we will serve you wholeheartedly and provide you with the most satisfactory products and services. Thank you again for your trust and support to our company!