Cold rolling is under the status of the processed by hot rolling plate, while in the process of machining for rolling will make the steel plate temperature, nonetheless called cold rolling. By hot rolling through continuous cold deformation of cold rolling, with poor mechanical properties, hardness is too high, must pass through annealing to restore its mechanical properties, without annealing called hard rolls. Hard coil is commonly used to do without bending, stretching products, thickness of 1.0 the following hard good luck or quadrilateral bending on both sides.

| GMW3399M-ST-S-CR980T/700Y-DP |

| GMW3032M-ST-S-CR180B2-UNCOATED-U |

| GMW3032M-ST-S-210P-UNCOATED-U |

| GMW3032M-ST-S-CR180IF-UNCOATED-U |

| GMW3032M-ST-S-CR210IF-UNCOATED-U |

| GMW3032M-ST-S-CR240IF-HUNCOATED-U |

| GMW3032M-ST-S-CR180B2-UNCOATED-U |

| GMW3032M-ST-S-CR210B2-UNCOATED-U |

| GMW3032M-ST-S-CR250B2-UNCOATED-U |

| GMW3032M-ST-S-CR300B2-UNCOATED-U |

| GMW3032M-ST-S-CR250LA-UNCOATED-U |

| GMW3032M-ST-S-CR240LA-UNCOATED-U |

| GMW3032M-ST-S-CR300LA-UNCOATED-U |

Cold rolled usually adopt the way of longitudinal rolling. Cold rolling production process generally includes raw materials preparation, rolling, degreasing, pickling, annealing (heat treatment), finishing, etc.

Cold-rolled hot-rolled products as raw materials, raw materials before cold rolling of phosphorus removal, to ensure that the surface of the cold-rolled products clean. Is to make the material of rolling deformation of the main process. Skim to remove rolling when attached to the metal rolling lubrication oil, to avoid pollution when annealed steel, also to prevent the increase of carbon for stainless steel. Annealing heat treatment, including intermediate annealing and finished product intermediate annealing is eliminated by recrystallization cold deformation which is caused by work hardening, to resume the plasticity of material and reduce the deformation resistance of the metal.

The purpose of the finished product heat treatment in addition to eliminated by recrystallization hardening. Is that according to the requirements of the product technology in order to obtain required by the organization (such as a variety of texture, etc.) and product performance (e.g., deep drawing, electromagnetic properties, etc.). Finishing includes checking, shear, straightening (flat), printing, sorting, packaging, etc.

Cold rolled products have high requirements, in order to prevent the product surface is scratched in transit. In addition to the above process external production when some special products have their own special processes. Such as rolling silicon steel plate, before the cold rolling for decarburizing annealing, must carry on the coating, high temperature annealing after rolling, stretching tension straightening (see) and tempering, etc.

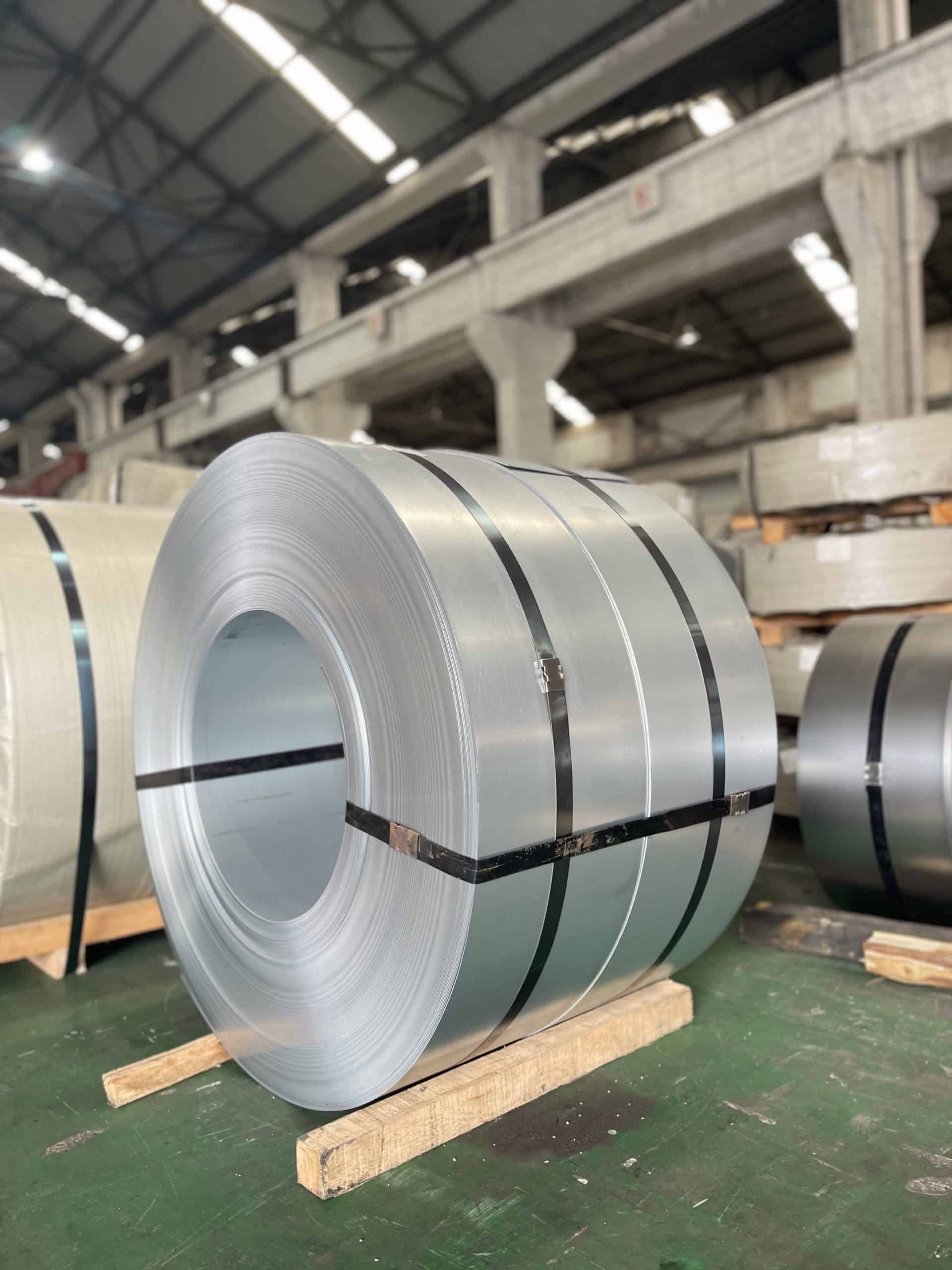

We are always good packaging products

We always pay attention to every detail, very good guarantee the quality of the product

FAQ About GMW3032M steel

What is GMW3032M steel?

GMW3032M steel refers to automotive steel that conforms to the global standard. All material settings are based on the global basic regulations, including the amount of metal, the type of steel product, the minimum yield strength and the standard of polishing type. The type of steel product is Cold-rolled CR products and hot-rolled HR products.

This steel grade is commonly used in structural applications in the automotive industry, such as chassis and body panels. GMW3032M has excellent mechanical properties, especially at high temperatures, making it ideal for use in high temperature environments. This steel grade also has good corrosion resistance and is easy to weld, making it a versatile choice for a variety of applications.

What are the chemical compositions of GMW3032M steel?

GMW3032M steel is a low carbon high strength steel commonly used in automotive applications. The chemical composition of GMW3032M steel includes:

– Carbon: 0.06-0.13%

– Manganese: 0.60-1.20%

– Silicon: 0.17-0.37%

– Phosphorus: ≦ 0.035%

– Sulfur: ≦ 0.040%

What are the physical properties of GMW3032M steel?

GMW3032M steel is a high strength low alloy steel specially designed for use in the automotive industry. The material has many physical properties that make it ideal for automotive manufacturing. First, GMW3032M steel is extremely strong and durable, meaning it can withstand the high temperatures and pressures involved in the car manufacturing process. Second, the material is highly resistant to corrosion, making it ideal for cars that may be exposed to harsh weather conditions. Finally, GMW3032M steel is also very weldable, meaning it can be easily joined together during fabrication.

What are the mechanical properties of GMW3032M steel?

GMW3032M is a high strength, low alloy steel with good formability, weldability and toughness. This material is commonly used in automotive and construction applications. The following are the mechanical properties of GMW3032M steel:

Yield Strength: 550 MPa (79,000 psi)

Tensile Strength: 760 MPa (110,000 psi)

Elongation: 18%

Reduction of area: 55%

Modulus of Elasticity: 190 GPa (28 x 106psi)

Shear Modulus: 75 GPa (11 x 106psi)

Brinell hardness: 269 HBW

What is the microstructure of GMW3032M steel?

Particle Size: By analysis, the particle size tested in accordance with ASTM E112 shall be continuous through the thickness. The particle size of the hot rolled substrate is No. 6 or smaller. The particle size of the cold-rolled matrix is No. 8 or smaller.

What are the welding requirements for GMW3032M steel?

GMW3032M steel has no special regulations for rolling welding of coils that are transferred from the production process of hot-rolled coils to cooling and cooling. Seam-welded coils that have been cold-rolled to allow drilling to inspect welded parts prior to stamping should be avoided as much as possible. Cold-rolled coils with exposed faces can be welded and punched for marking. Welding of non-exposed cold-rolled coils is not permitted unless specifically permitted by the local organization.

What are the thermal properties of GMW3032M steel?

GMW3032M steel is a low carbon high strength steel commonly used in automotive applications. The thermal properties of GMW3032M steel make it an ideal material for use in environments where extreme temperatures are a concern. GMW3032M steel has a melting point of about 1450°C and a boiling point of about 2700°C. GMW3032M steel has a density of 7.85 g/cm3.

What are the characteristics of GMW3032M steel?

The automotive industry relies on steel for a variety of components, from engine blocks and transmission housings to exhaust systems and suspension systems. But not all steels are created equal – different types have different properties that make them better suited for certain applications than others.

What types of GMW3032M steel are there?

A variety of automotive steels are used in today’s vehicles. The most common type of steel is mild steel, used in approximately 80% of automotive applications. Other types of steel used in the automotive industry include:

- High Strength Low Alloy (HSLA) Steels – Steels such as GMW3032 CR240LA may offer better mechanical properties and/or greater resistance to atmospheric corrosion than conventional carbon steels. These steels usually contain small amounts of one or more alloying elements such as copper, nickel, chromium, molybdenum, vanadium and niobium.

- Dual phase (DP) steels – such as GMW3032M-ST-S CR300DP steels, are high strength steels that contain both ferritic and martensitic microstructures. These steels typically have yield strengths in the range of 500 to 700 MPa.

- Interstitial atom-free steel (IF) – such as GMW3032 CR180IF, due to the low content of C and N in this steel, adding a certain amount of Ti and Nb makes the C and N atoms in the steel fixed as carbides and nitrides, so that There are no interstitial atoms in steel, so it is called interstitial-free steel. Interstitial-free steel has low yield point and yield strength ratio, high elongation, high plastic strain ratio, high work hardening index and other deep drawing properties, and has no aging.

What are the advantages of GMW3032M steel?

There are many benefits to using automotive steel, including its durability, strength and resistance to wear. Automotive steel is also relatively easy to machine and can be made in a variety of shapes and sizes. Additionally, automotive steel is less prone to corrosion than other types of metals, making it an ideal material for use in bodywork and other exposed areas.

What are the applications of GMW3032M steel?

GMW3032M steel is a high strength, low alloy steel commonly used in automotive applications. This steel is made by adding vanadium and molybdenum to a base of iron and carbon. This results in steel with high strength and toughness. GMW3032M also has good weldability, making it suitable for automotive body panels and other welding applications.

GMW3032M steel is an excellent material choice for many different applications. Its properties such as strength, durability, flexibility and cost-effectiveness make it ideal for a variety of uses. With its high tensile strength, corrosion resistance and weldability, GMW3032M steel can help you get the job done quickly and efficiently with results you can trust. Whether you want to build structures or manufacture mechanical components, GMW3032M steel should be your material of choice.

How to Choose the Right Automotive Steel for Your Vehicle?

There are a few things to consider when choosing the right type of automotive steel for your vehicle. The first is the intended use of the vehicle. If you’re looking for a steel that can withstand high temperatures, then you’ll want to choose a heat-resistant alloy. If you need strong and durable steel, then you’ll want to choose a high-strength alloy. The second consideration is the weight of the vehicle. Lighter steel will be more fuel efficient, while heavier steel will be more durable. The third consideration is the cost of steel. Cheaper steel may not be as strong and durable as more expensive steel, but it may suit your needs. When selecting automotive steel, it is important to consider these factors in order to choose the right type for your vehicle.