The meaning of HC260LA

HC260LA is a designation that refers to a specific type of high-strength, low-alloy (HSLA) steel. “LA” stands for low-alloy. This particular steel grade is commonly used in the automotive industry and other manufacturing applications that require materials with excellent strength and formability.

The HC260LA steel has a minimum yield strength of 260 megapascals (MPa). The “LA” designation suggests that it has been designed for improved formability, which means it can be bent, stamped, or otherwise formed without cracking or breaking. This makes it suitable for various shaping processes, including cold forming, roll forming, and bending.

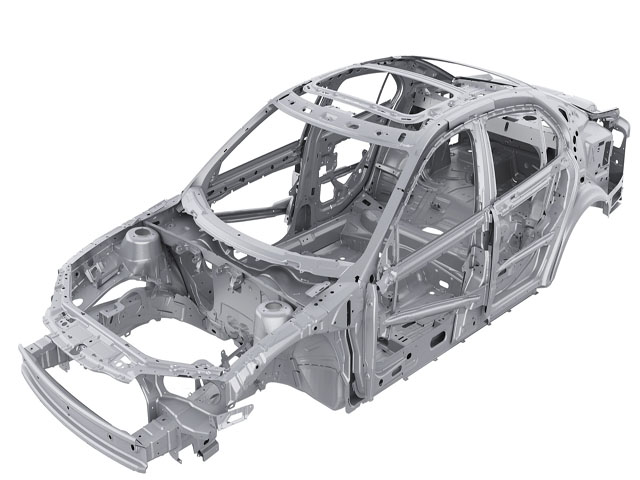

HC260LA is often used in the production of structural components, such as chassis parts, reinforcement elements, and other components that require both high strength and good formability. It offers a balance between strength and ductility, making it suitable for applications where both properties are crucial.

What is High Strength Low Alloy Steel HSLA?

In low carbon steel, the addition of microalloying elements, such as niobium, titanium, and vanadium, either individually or in combination, plays a significant role in enhancing its properties. These elements are added in small amounts to form carbonitride particles, which precipitate within the steel matrix, contributing to strengthening the material.

The carbonitride particles act as obstacles to dislocation movement, effectively impeding the deformation of the steel. This leads to an increase in the strength of the material, as well as improved resistance to deformation under applied loads. The presence of these particles also helps to prevent grain growth during the steel manufacturing process, thereby refining the grain size.

By refining the grain structure, the steel can achieve higher strength. Smaller grain size means that there are more grain boundaries, which act as barriers to dislocation movement and contribute to strengthening the steel. Therefore, the addition of microalloying elements aids in both precipitation strengthening through carbonitride particles and grain refinement, resulting in improved mechanical properties.

Additionally, low carbon steels with microalloying elements generally exhibit good weldability. The presence of these elements helps to prevent the formation of undesirable phases and microstructural defects during welding. This reduces the risk of cracking and ensures that the welded joints maintain the desired properties and structural integrity.

The typical structure of low carbon steels with microalloying elements is primarily ferrite, which is a relatively soft and ductile phase. The presence of a small amount of carbide, resulting from the precipitation of carbonitride particles, further contributes to strengthening the steel. This combination of ferrite and carbide provides a balance of strength and ductility, making the steel suitable for a wide range of applications.

Composition and characteristics of HC260LA

Chemical composition of HC260LA

C(MAX): 0.1%

Mn(MAX): 1%

Si(MAX): 0.5%

Mechanical properties of HC260LA

YS(MPa): 260-330

TS(MPa): 350-430

EL(%) ≥26%

n ≥ 0.14

Advantages of High Strength Low Alloy Steel HSLA HC260LA

High Strength Low Alloy Steel (HSLA) grade HC260LA, characterized by its high strength and good formability, offers several advantages. Firstly, its high strength allows for the production of lighter and more durable components, contributing to weight reduction in various applications without compromising structural integrity. This makes it particularly desirable in the automotive and transportation industries, where weight savings can improve fuel efficiency and overall performance. Additionally, HC260LA exhibits good formability, enabling it to be easily shaped and formed without sacrificing its mechanical properties. This makes it suitable for complex and intricate designs, allowing manufacturers to create components with intricate geometries. Moreover, HC260LA possesses good weldability, ensuring reliable and efficient joining of parts during fabrication. Overall, the combination of high strength, formability, and weldability makes HSLA HC260LA a versatile material for applications requiring lightweight, strong, and easily fabricated components.

Common Applications of High Strength Low Alloy Steel HSLA HC260LA

High Strength Low Alloy Steel (HSLA) grade HC260LA finds widespread applications across various industries. In the automotive sector, it is commonly used for the production of structural components like chassis parts, reinforcement elements, and crash-resistant parts. Its high strength and good formability make it ideal for manufacturing lightweight yet robust components, contributing to improved fuel efficiency and vehicle safety. Additionally, HC260LA is utilized in the construction industry for structural purposes, such as in the fabrication of bridges, buildings, and infrastructure where a balance of strength and formability is crucial. It is also employed in the manufacturing of agricultural machinery, appliances, and equipment requiring high strength and good weldability. Overall, the versatile properties of HSLA HC260LA make it a preferred choice for various applications that demand a combination of strength, formability, and weldability.