What is isotropic high-strength steel IS?

Isotropic high-strength steel is a type of steel that exhibits excellent mechanical properties, specifically designed for applications where both strength and formability are crucial, such as the production of automotive outer coverings. The term “isotropic” refers to the material’s consistent mechanical behavior in all directions, which means it possesses uniform properties regardless of the orientation of forces applied to it.

One important characteristic of isotropic high-strength steel is the limitation of the plastic strain ratio (r). The plastic strain ratio is a measure of the non-uniform deformation that occurs during plastic deformation. By limiting the plastic strain ratio, this type of steel minimizes the occurrence of localized deformation and ensures more uniform stretching or forming.

The isotropic properties of this steel allow it to undergo stretch forming processes effectively. Stretch forming is a manufacturing technique used to shape sheet metal into complex forms by stretching it over a die. In this process, the steel is subjected to controlled stretching forces, and the isotropic nature of the material ensures that it stretches uniformly in all directions without excessive thinning or tearing.

The microstructure of isotropic high-strength steel is predominantly ferrite. Ferrite is a crystal structure commonly found in iron-based alloys. It has a body-centered cubic (BCC) arrangement of atoms and exhibits relatively good ductility and toughness. The ferrite microstructure contributes to the favorable mechanical properties of isotropic high-strength steel, including its formability, strength, and resistance to deformation.

Composition and characteristics of HC220I

Chemical composition of HC220I

C(MAX): 0.06%

Mn(MAX): 0.8%

Si(MAX): –

Mechanical properties of HC220I

YS(MPa): 220-270

TS(MPa): 300-400

EL(%) ≥ 34%

r ≥ 1.4

n ≥ 0.18

Advantages of Isotropic High Strength Steel IS HC220I

Isotropic high-strength steel, such as HC220I, offers several advantages for various applications. Here are some of the key advantages:

High Strength: Isotropic high-strength steel, including HC220I, possesses superior strength compared to conventional steels. It offers high tensile strength, which makes it suitable for applications where structural integrity and load-bearing capacity are crucial.

Good Formability: HC220I exhibits excellent formability, particularly in stretch forming processes. Its isotropic nature allows for uniform stretching without significant thinning or tearing. This formability is advantageous for industries such as automotive manufacturing, where complex shapes and precise forming are required.

Lightweight: Isotropic high-strength steel, including HC220I, allows for the production of lightweight components without compromising on strength. This is beneficial for applications where weight reduction is desired, such as in the automotive and aerospace industries. It enables improved fuel efficiency in vehicles and increased payload capacity in aircraft.

Enhanced Crashworthiness: The high strength of HC220I contributes to improved crashworthiness in automotive applications. It can absorb and distribute impact energy effectively, providing enhanced safety for occupants. The isotropic properties of this steel also contribute to predictable deformation patterns during crashes, which aids in designing structures for optimal energy absorption.

Improved Fuel Efficiency: By utilizing isotropic high-strength steel like HC220I in vehicle manufacturing, automakers can reduce the weight of the vehicle without sacrificing strength and safety. The reduced weight leads to improved fuel efficiency and lower emissions, making it an environmentally friendly choice.

Cost Savings: While isotropic high-strength steel may have a higher initial material cost compared to conventional steels, it offers potential cost savings in the long run. Its high strength allows for the use of thinner gauges, reducing material consumption. Additionally, its excellent formability can simplify manufacturing processes and reduce production time and costs.

Common Applications of Isotropic High Strength Steel IS HC220I

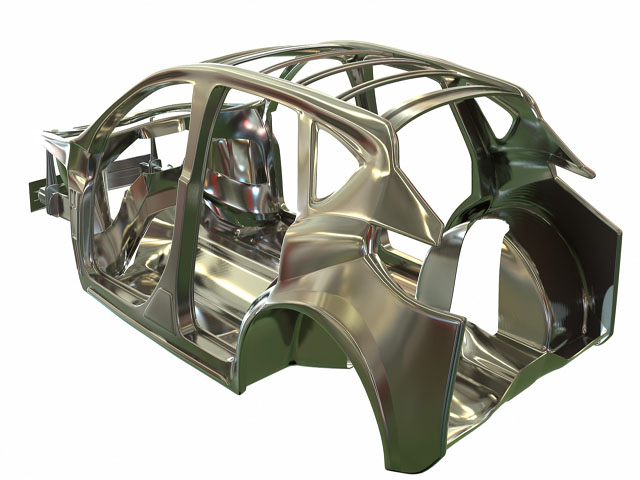

Isotropic high-strength steel, specifically HC220I, finds wide-ranging applications in various industries due to its exceptional mechanical properties. HC220I offers a unique combination of high strength, good formability, and lightweight characteristics, making it well-suited for demanding applications. Commonly used in automotive, aerospace, and construction sectors, HC220I is employed in the production of automotive outer coverings, structural components, and lightweight designs where strength and formability are critical. Its isotropic nature ensures uniform deformation in all directions, making it ideal for stretch forming processes. Additionally, HC220I’s enhanced crashworthiness, improved fuel efficiency, and potential cost savings further contribute to its popularity in industries that prioritize performance, safety, and sustainability.