VW 50065 CR210LA

VW 50065 CR210LA is a steel product that provides excellent value for money. It offers a wide range of benefits, including high strength, durability and good weldability. VW 50065 CR210LA is available in a variety of grades, making it ideal for a range of applications. The company has an extensive network of dealers and distributors, making it easy to find the right product for your needs. VW 50065 CR210LA is backed by a team of experts who are always on hand to offer support and advice. With a commitment to quality and customer service, VW 50065 CR210LA is the perfect choice for all your steel needs.

VW 50065 CR210LA is introduced and Mechanical properties (Mpa):

| The material | VW 50065 CR210LA | |||||

| Chemical composition | C% | Si% | Mn% | P% | S% | Ai% |

| ≤ 0.10 | ≤ 0.50 | ≤ 1.00 | ≤ 0.080 | ≤ 0.030 | ≥ 0.015 | |

| Mechanical properties of | YS | TS(MPa) | EL | |||

| 210-300 | 310-410 | ≥29 | ||||

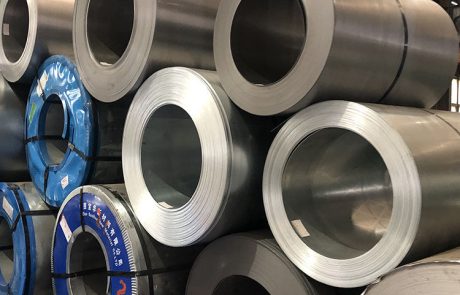

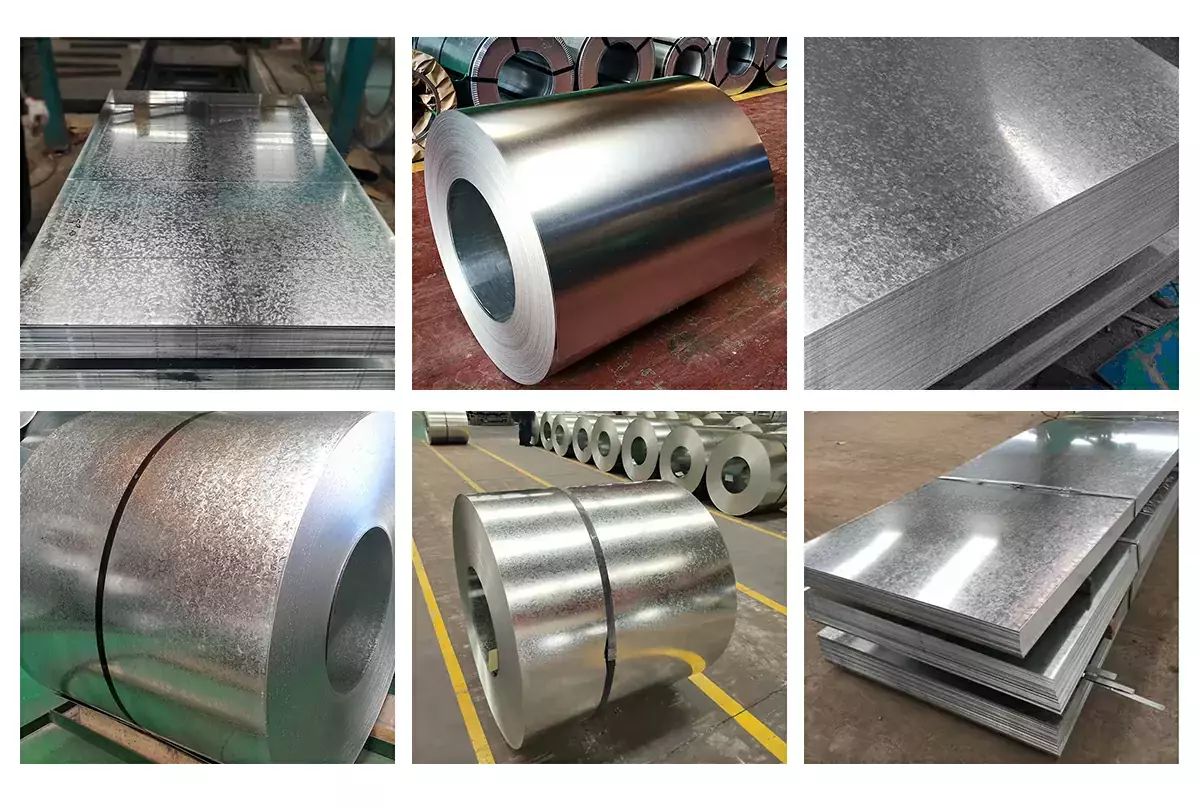

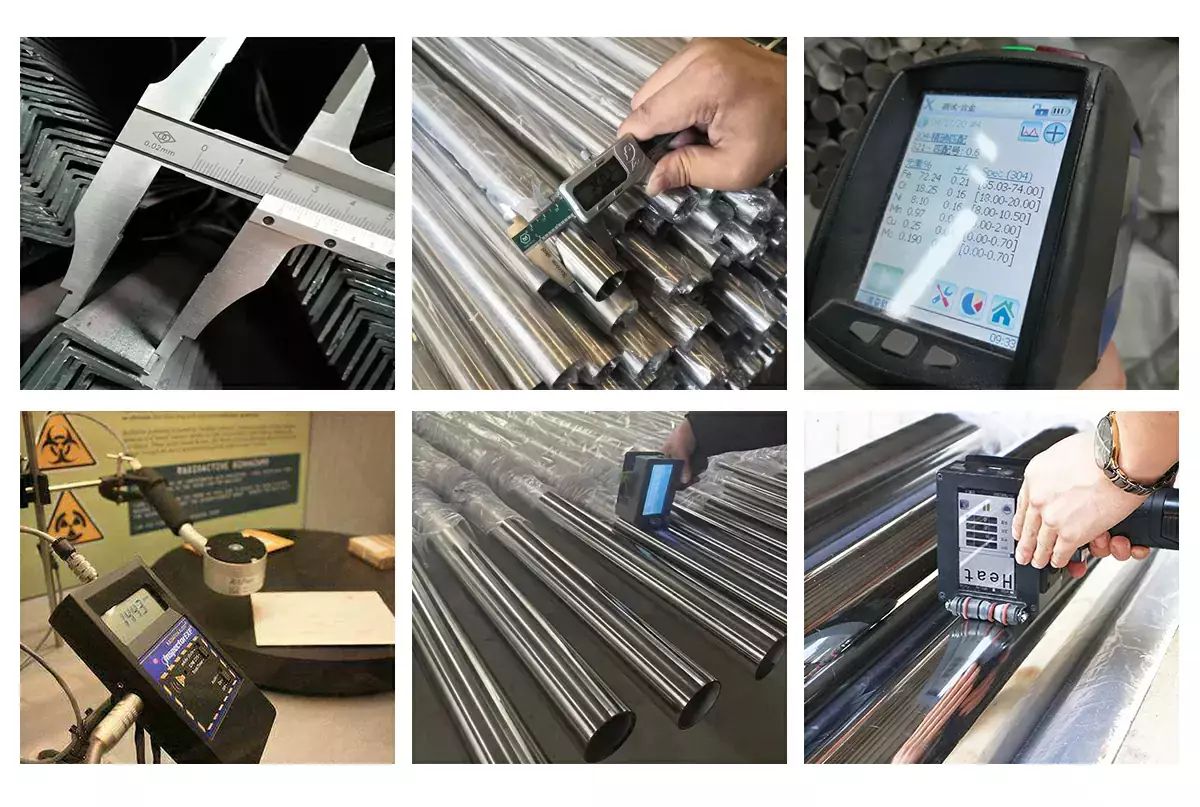

Steel Photos

Steel Packing

Quality Control

CR210LA Steel FAQS

What is CR210LA steel?

This is a kind of weldable low-carbon engineering structural steel. Its carbon content is usually less than 0.25%, which has a higher yield point than ordinary carbon structural steel σ S or yield strength σ 0.2 (30~80kgf/mm2) and yield ratio σ s/ σ B (0.65~0.95), good cold and hot processing formability, good weldability, low cold brittleness tendency, notch and aging sensitivity, and good corrosion resistance to atmosphere and seawater. Its alloy element content is low, generally less than 2.5%, and it is used after hot rolling or simple heat treatment (non quenched and tempered); Therefore, this kind of steel can be produced in large quantities and widely used. The output of low-alloy high-strength steel in developed industrial countries accounts for about 10% of the steel output (see alloy steel)

What is the chemical composition of CR210LA steel?

Chemical composition: C ≤ 0.12

Si≦0.50

Mn≦1.50

P≦0.030

S≦0.030

ALs≥0.015

What is the rolling temperature of CR210LA steel?

Heating temperature: 1200 ℃

Final rolling temperature: 900 ℃

Coiling temperature: 500~700 ℃

What are the physical properties of CR210LA steel?

Yield strength: ≥ 210MPa,

Tensile strength: ≥ 340MPa

Elongation after fracture: ≥ 22%

What is the production process of CR210LA steel?

Steelmaking process flow: scrap+hot metal – electric furnace – ladle – LF furnace – VD furnace – ① continuous casting – continuous casting billet

What are the main characteristics of CR210LA steel?

- Good comprehensive mechanical properties

- Good weldability, cold and hot workability and corrosion resistance. Grade C, D and E steels have good low-temperature toughness

- High strength, especially in the normalizing or normalizing and tempering state with relatively high comprehensive mechanical properties, and in the normalizing, normalizing and tempering or quenching and tempering state with very high comprehensive mechanical properties, all of which are deoxidized with aluminum, and the quality grade is C, D, E, which can ensure the good toughness of steel and high strength steel products

What type of low alloy steel is CR210LA steel?

There are two types of cold-rolled low alloy steel:

- Ordinary quality low alloy steel:

Ordinary quality low alloy steel refers to low alloy steel used for general purposes without special quality control requirements in the production process. The following conditions shall be met simultaneously:

1) The alloy content is relatively low (in line with the provisions of the content limit value for the alloy elements of low alloy steel);

2) Heat treatment is not specified (annealing, normalizing, stress relief and softening treatment are not treated as heat treatment);

- High quality low alloy steel:

High-quality low-alloy steel refers to low-alloy steel other than ordinary quality low-alloy steel and special quality low-alloy steel. In the production process, special quality control is required (such as reducing sulfur and phosphorus content, controlling grain size, improving surface quality, increasing process control, etc.) to achieve special quality requirements than ordinary quality low-alloy steel (such as good brittle fracture resistance, good cold forming performance, etc.), However, the production control and quality requirements of this steel are not as strict as those of special quality low alloy steel.

- Special quality low alloy steel:

Special quality low alloy steel refers to the need to strictly control the quality and performance in the production process, especially the strict control

Low-alloy steel with sulfur, phosphorus and other impurities content and purity) shall meet at least one of the following conditions, and limit the content of non-metallic inclusions and/or the uniformity of internal materials, such as the resistance to lamellar tearing of steel plate:

The maximum value of phosphorus content and/or sulfur content shall be strictly limited, and the following provisions shall be met:

Smelting analysis value: ≤ 0.020%;

Finished product analysis value: ≤ 0.025%;

CR210LA steel belongs to ordinary quality low alloy steel.

What are the applications of CR210LA steel?

CR210LA steel has good weldability and formability, and can be used for the following purposes:

Ships, boilers, pressure vessels, oil storage tanks, bridges, power station equipment, lifting and transportation machinery and other welding structures with high loads, large ships, bridges, power station equipment, medium and high pressure boilers, high pressure vessels, rolling stock, lifting machinery, mining machinery and other large welding structures.