VW 50065 CR240LA

VW 50065 CR240LA is a steel product that offers excellent corrosion resistance and high strength. It is perfect for parts that are exposed to extreme weather conditions or elements. VW 50065 CR240LA can be used in a variety of applications, including automotive, construction, and marine. Solucky Steel is proud to offer VW 50065 CR240LA at an competitive price. For more information about this product, please contact us today.

VW 50065 CR240LA is introduced and Mechanical properties (Mpa):

| The material | VW 50065 CR240LA | ||||||

| Chemical composition | C% | Si% | Mn% | P% | S% | Ai% | Ti% |

| ≤ 0.10 | ≤ 0.50 | ≤ 1.00 | ≤ 0.030 | ≤ 0.025 | ≥ 0.015 | ≤ 0.15 | |

| Mechanical properties of | YS | TS(MPa) | EL | ||||

| 240-320 | 320-420 | ≥27 | |||||

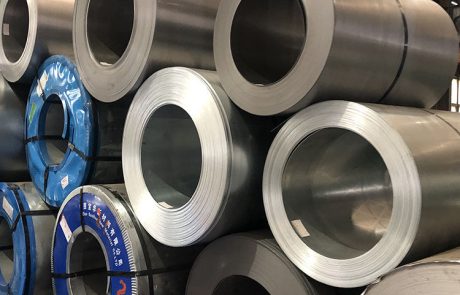

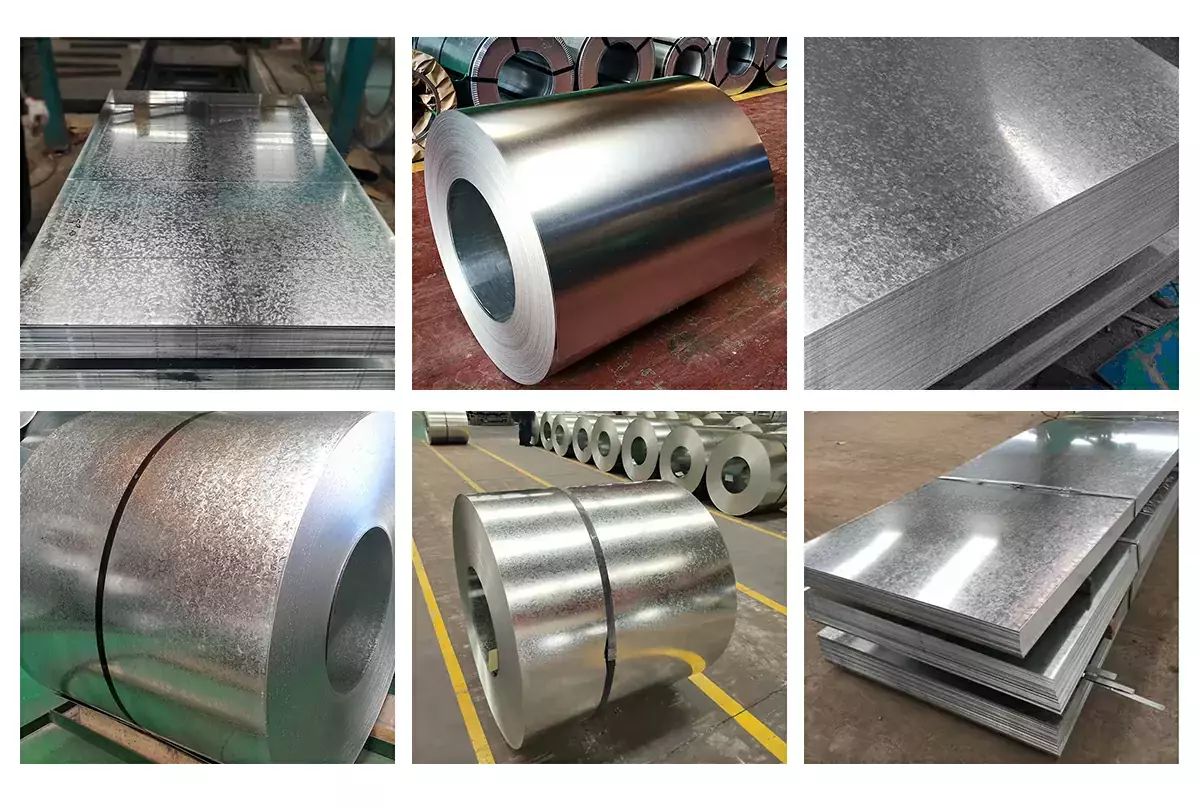

Steel Photos

Steel Packing

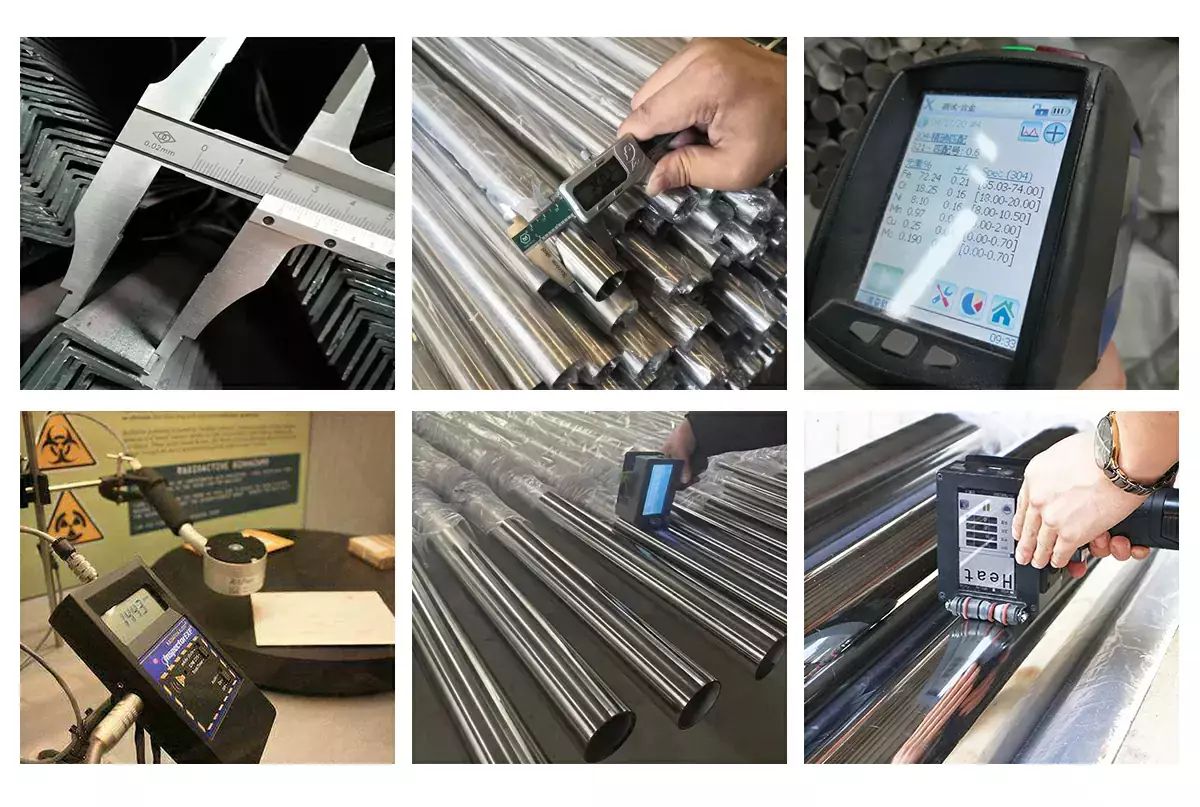

Quality Control

FAQ About Cr240la Steel

What is Cr240la steel?

Cr240la steel is a high-performance alloy containing chromium, molybdenum, and nickel. It provides superior strength and wear resistance and is used in the production of automotive parts, power tool components, sporting goods, knives and other cutting tools. In addition to its impressive strength and durability properties, Cr240la steel is also highly corrosion resistant, making it an ideal choice for manufacturing products that will be exposed to harsh conditions.

What are the properties of Cr240la steel?

Cr240la steel is a high-strength, low-alloy steel that possesses a number of properties that make it ideal for use in a variety of applications. First and foremost, Cr240la steel has an exceptionally high strength-to-weight ratio. This means that it is able to withstand significant loads without being excessively heavy. Additionally, Cr240la steel is highly resistant to corrosion and wear, making it ideal for use in environments where these factors are present. Finally, Cr240la steel has a very low coefficient of thermal expansion, meaning that it will not expand or contract significantly in response to changes in temperature.

What is the chemical composition of Cr240la steel?

Cr240la steel is an austenitic stainless steel that contains at least 18% chromium and 8% nickel. The composition of Cr240la steel also includes other Alloying elements such as molybdenum, silicon, manganese, and nitrogen.

What are the physical properties of Cr240la steel?

Cr240la steel is an alloy of iron and chromium, containing between 2 and 3% chromium. It is known for its high strength and hardness, as well as its ability to resist wear and tear. Cr240la steel is often used in applications where high levels of wear and tear are expected, such as in construction or mining.

How to use Cr240la steel?

Cr240la steel is a versatile material that can be used for a variety of applications. Here are some tips on how to use Cr240la steel:

-When choosing Cr240la steel for your project, consider the thickness, width, and length of the material.

-Keep in mind that Cr240la steel is a high carbon content material, so it should be used in projects where strength and durability are required.

-If you are looking for a corrosion resistant material, Cr240la steel is a good choice. However, it is important to note that this material is not stainless steel.

-If you need to cut or weld Cr240la steel, be sure to use the proper equipment and techniques. This material can be difficult to work with if you are not experienced.

What are the applications of Cr240la steel?

Crla steel is an alloy steel that has a wide range of applications. It is commonly used in the automotive and aerospace industries, as well as in the construction and manufacturing industries. Crla steel is known for its high strength and durability, making it an ideal material for many different applications.

What are the advantages of Cr240la steel?

There are many advantages of Cr240la steel, which is why it is often used in construction and other applications. Some of the main advantages of Cr240la steel include:

- It is extremely strong and durable, making it ideal for use in construction projects.

- It is resistant to corrosion and weathering, meaning it will last longer than other types of steel.

- It is easy to work with, meaning it can be used in a variety of applications.

- It is relatively inexpensive, making it a cost-effective option for many projects.

How does cr240la steel compare to other steels?

Cr240la steel is a kind of low alloy high strength structural steel. Its yield strength is about 240Mpa. It has good welding performance and can be used in architecture, machinery manufacturing, shipbuilding and bridges. However, its price is higher than that of other steels, such as SS400 and Q235.

How to care for Cr240la steel?

Cr240la steel is a high-strength, low-alloy steel that offers an excellent balance of strength and ductility. Cr240la steel is easily welded and formed, making it an ideal choice for a variety of structural applications. Despite its strength, Cr240la steel is lightweight and easy to work with. Here are some tips on how to care for Cr240la steel to keep it looking its best:

– Keep Cr240la steel clean and free of dirt, grease, and other contaminants. A clean surface will help ensure optimal corrosion resistance and prevent the formation of rust.

– Inspect Cr240la steel regularly for signs of wear or damage. If any damage is found, repair or replace the affected component as soon as possible to prevent further deterioration.

– Store Cr240la steel in a cool, dry place when not in use. Avoid exposure to excessive heat or moisture, which can accelerate corrosion.

What are the advantages of using Cr240la steel?

Cr240la steel is an excellent choice for a variety of applications due to its many advantages. Cr240la steel is highly corrosion resistant, making it ideal for use in environments where corrosion is a concern. Cr240la steel is also very strong and durable, meaning it can withstand high levels of stress and wear and tear. Additionally, Cr240la steel is easy to work with and can be fabricated into a variety of shapes and sizes.

What are the disadvantages of using Cr240la steel?

Cr240la steel is not as strong as other steels, so it is not suitable for structural applications. It is also susceptible to corrosion, so it must be protected from moisture and chemicals. Cr240la steel is also difficult to weld, so it is not often used in fabrications or repairs.

How is Cr240la steel used?

Cr240la steel is used in a variety of applications, including:

-Automotive parts

-Construction materials

-Cookware

-Industrial equipment

-Surgical instruments

Cr240la steel is an alloy of chromium and iron, and is known for its high corrosion resistance and strength. It is often used in environments where there is high moisture or chemical exposure, such as in automotive parts or construction materials. Cr240la steel can also be found in cookware and industrial equipment. Due to its high corrosion resistance, it is also commonly used in surgical instruments.