VW 50065 CR340LA

VW 50065 CR340LA is a high strength, low alloy steel that was specifically developed for automotive applications. The VW 50065 CR340LA designation stands for ” VW 50065 Cold Rolled 340 Megapascal Low Alloy.” This particular type of steel is often used in the construction of cars and trucks, as it provides superior strength and durability. In addition, VW 50065 CR340LA steel is highly resistant to corrosion, making it an ideal choice for vehicles that are exposed to harsh weather conditions. VW 50065 CR340LA steel is produced by Solucky Steel, a leading manufacturer of automotive steel products. Solucky Steel has been supplying VW 50065 CR340LA steel to the automotive industry for over 20 years, and is se0en as a trusted supplier of high quality automotive materials. If you are in need of VW 50065 CR340LA steel for your next automotive project, be sure to contact Solucky Steel for a quote. Thanks for reading!

VW 50065 CR340LA is introduced and Mechanical properties (Mpa):

| The material | VW 50065 CR340LA | |||||||

| Chemical composition | C% | Si% | Mn% | P% | S% | Ai% | Ti% | Nb% |

| ≤ 0.12 | ≤ 0.50 | ≤ 1.50 | ≤ 0.030 | ≤ 0.025 | ≥ 0.015 | ≤ 0.15 | ≤ 0.09 | |

| Mechanical properties of | YS | TS(MPa) | EL | |||||

| 340-430 | 410-520 | ≥21 | ||||||

VW 50065 CR340LA Performance

Its strength is very high, but the toughness and weldability poor, more hard, brittle, surface brightness.

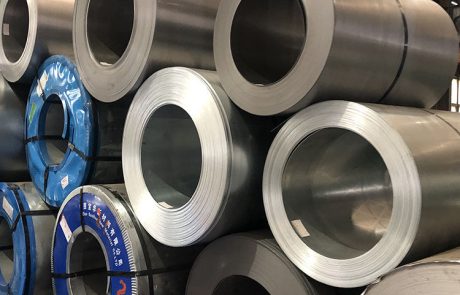

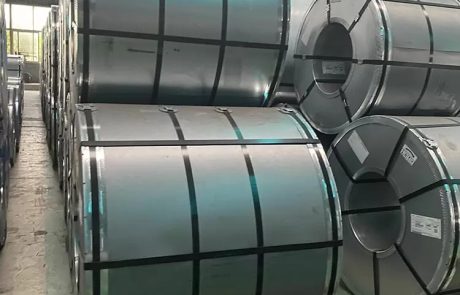

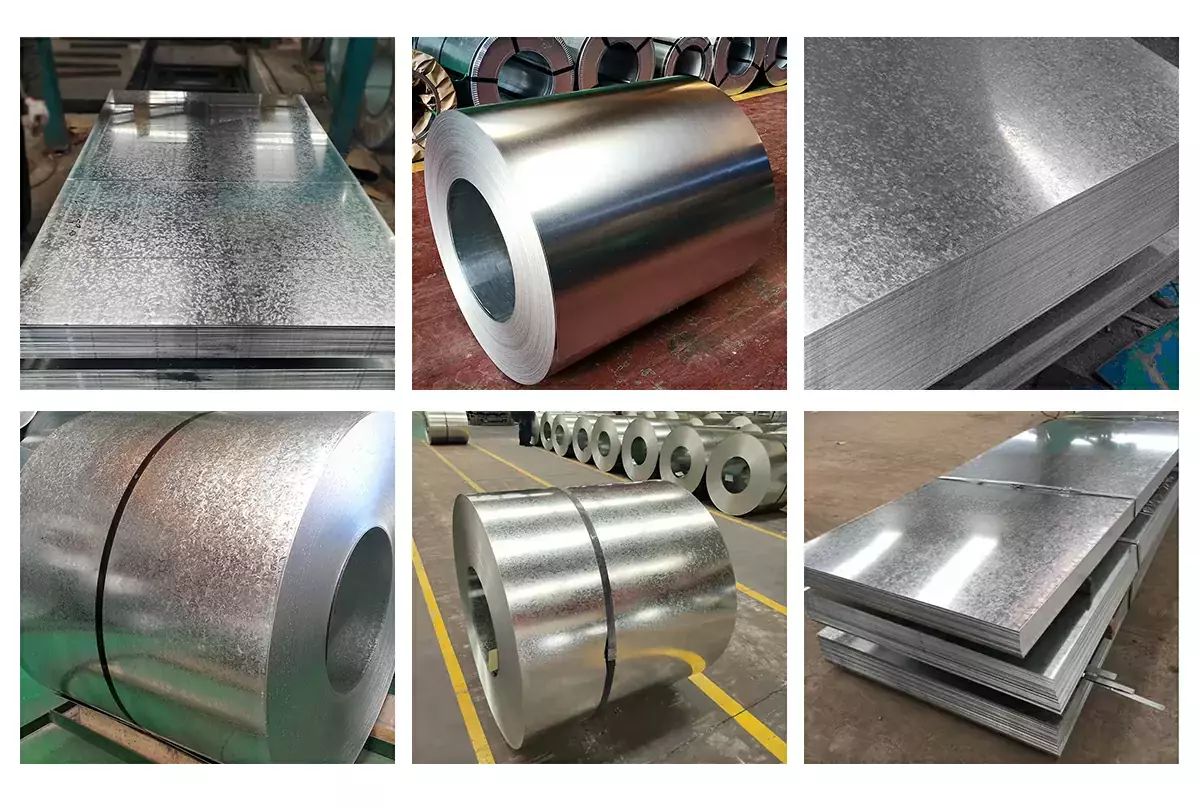

Steel Photos

Steel Packing

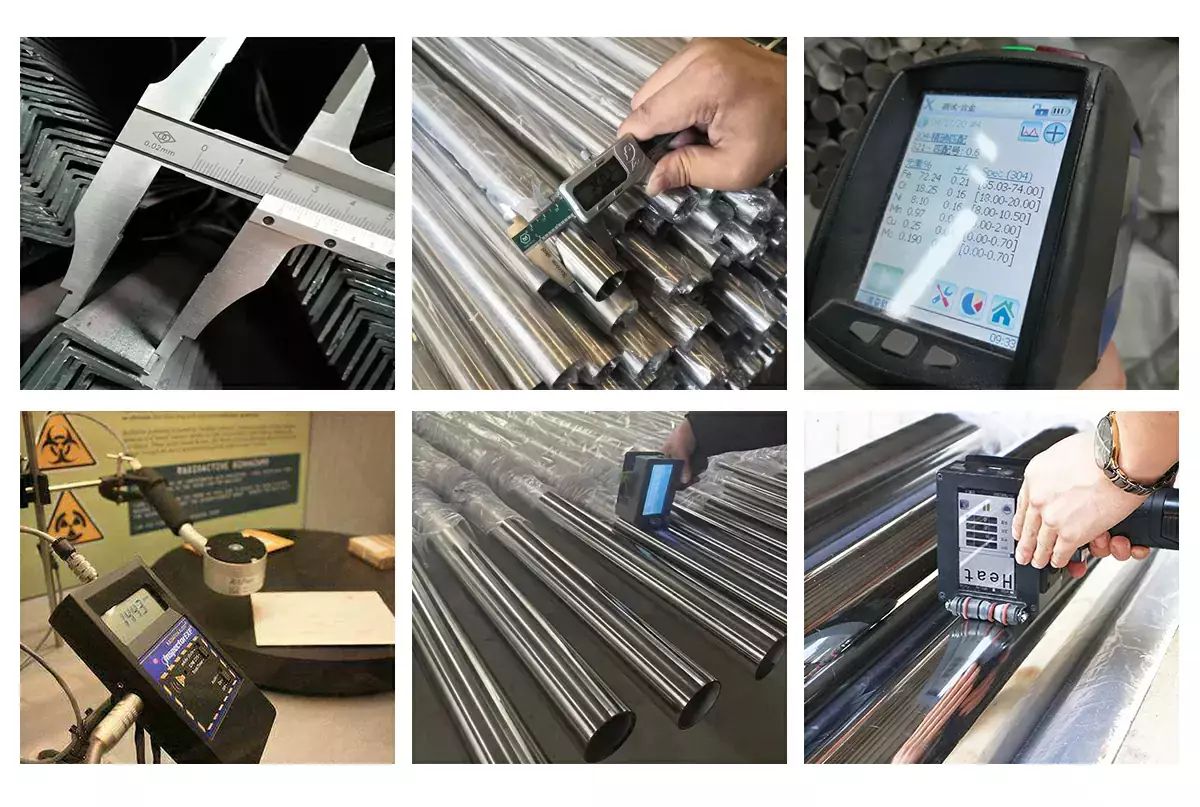

Quality Control

FAQ About Cr340la Steel

What is cr340la steel?

Cr340la steel is a low carbon, high strength steel that is often used in construction and manufacturing. It has good weldability and formability, and is often used in applications where weight or stress is a concern. Cr340la steel is sometimes called “ mild steel ” because of its low carbon content.

What are the applications of cr340la steel?

Cr340la steel is a versatile material that can be used in a variety of applications. Its high strength and durability make it ideal for use in construction, while its corrosion resistance makes it ideal for use in the automotive and aerospace industries.

How to weld cr340la steel?

Welding of CR340LA steel is generally not recommended, as the high carbon content makes the steel prone to cracking. However, if absolutely necessary, the following procedure should be followed:

1. Preheat the base metal to 400°F (204°C).

2. Perform a welding test on a scrap piece of CR340LA steel to ensure that the welder is able to produce a sound weld.

3. If using an arc welder, set the amperage at the lowest possible setting that will still produce a sound weld.

4. Weld in short bursts, allowing the base metal to cool between welds.

5. Immediately after welding, stress-relieve the base metal by heating it to 1200°F (649°C) and holding it at that temperature for two hours.

What are the uses for cr340la steel?

Cr340la steel is a versatile material that can be used for a variety of applications. Its high strength and durability make it ideal for use in construction, while its low carbon content makes it suitable for use in a variety of industries, including automotive and aerospace.

What are the advantages of cr340la steel?

There are many advantages of cr340la steel. It is a strong, durable and versatile material that can be used in a wide range of applications. It is also resistant to corrosion and has a high resistance to wear and tear. Cr340la steel is also easy to weld and can be machined to create parts with a high degree of precision.

What are the disadvantages of cr340la steel?

Despite its many advantages, there are some disadvantages to using CR340LA steel. One of the primary drawbacks is its high cost. This can be a deterrent for some companies, especially those on a tight budget. Additionally, CR340LA steel is difficult to weld and work with, which can add to the costs associated with using this material.

What s the manufacturing process of CR340LA?

The Cold Rolled Low Alloy (CR340LA) manufacturing process begins with a hot rolled low carbon steel that is first annealed to make the steel more pliable. The annealed sheet is then placed between cold rolled sheets and passed through rollers that squeeze thehot rolled sheet, thereby making it thinner and longer. These Cold Rolled Low Alloy sheets are then annealed again to make the steel even more pliable before being passed through yet more cold rollers. This process continues until the desired thickness and length are achieved.

How is CR340LA Made?

CR340LA is made by combining two different materials. The first material is a high-strength, lightweight aluminum alloy. The second material is a high-strength, high-modulus carbon fiber. These two materials are combined using a patented process that results in a product that is significantly lighter than traditional aluminum alloys, while still maintaining the same strength and stiffness.

What is the CR340LA steel heat treatment process?

CRLA steel is an alloy steel that is commonly used in the production of various types of tools and machinery. The steel is composed of carbon, manganese, silicon, chromium, molybdenum, vanadium, and tungsten.

The CR340LA steel heat treatment process involves heating the steel to a temperature between 1120-1180°C (2048-2156°F) in a furnace or heat treater. The steel is then cooled rapidly by quenching it in water or oil. This process hardens the steel and makes it more durable.

What are the benefits of heat treating CR340LA steel?

CR340LA steel is a popular choice for heat treating because it is highly resistant to wear and tear. The main benefit of heat treating CR340LA steel is that it increases the lifespan of the material, making it ideal for use in high-wear applications. Heat treating also enhances the strength and hardness of the steel, which makes it more resistant to damage from impact or abrasion. In addition, heat treating can improve the corrosion resistance of CR340LA steel, making it an ideal choice for use in environments where there is a risk of exposure to corrosive materials.

How to care for cr340la steel?

When caring for cr340la steel, it is important to first understand what type of steel it is. Cr340la steel is a high carbon stainless steel, which means it has a higher carbon content than other types of stainless steel and is more prone to rusting. However, with proper care, cr340la steel can last for many years without any problems.

The best way to care for cr340la steel is to keep it clean and dry. If the steel becomes wet, it should be dried immediately to prevent rusting. It is also important to avoid exposing the steel to strong chemicals or cleaners, as these can damage the finish. When cleaning cr340la steel, use only a mild soap and water solution. Be sure to rinse the area well afterwards to remove any soap residue.

If you notice any rust on cr340la steel, it is important to remove it as soon as possible. Rust can spread quickly and cause serious damage if left unchecked. The best way to remove rust is with a fine grade of sandpaper or a wire brush. Once all the rust has been removed, be sure to apply a protective coating of oil or wax to help prevent future rusting.