VW 50065 CR380LA

VW 50065 CR380LA steel is a high-strength, low-alloy steel that provides excellent weldability and formability. This material is commonly used in the automotive industry for a variety of applications, including chassis, suspension, and body panels. VW 50065 CR380LA steel offers superior strength and ductility, making it an ideal choice for many automotive applications. Solucky Steel is proud to offer VW 50065 CR380LA steel to our customers. This material is available in a variety of thicknesses and widths to meet your specific needs. Contact us today to learn more about this versatile material. With our VW 50065 CR380LA steel, you can be sure that you’re getting the highest quality product on the market. Order yours today!

VW 50065 CR380LA is introduced and Mechanical properties (Mpa):

| The material | VW 50065 CR380LA | |||||||

| Chemical composition | C% | Si% | Mn% | P% | S% | Ai% | Ti% | Nb% |

| ≤ 0.12 | ≤ 0.50 | ≤ 1.60 | ≤ 0.030 | ≤ 0.025 | ≥ 0.015 | ≤ 0.15 | ≤ 0.09 | |

| Mechanical properties of | YS | TS(MPa) | EL | |||||

| 380-470 | 450-560 | ≥19 | ||||||

Related to the difference between

1, appearance and surface quality: because of the cold plate is, resulting from the hot plate in cold rolling process and cold rolling at the same time also can do some surface finishing so cold plate on the surface quality (such as surface roughness, etc.) better heat plate, so if the product after the sequence on the quality of paint coating, such as there are higher requirements, generally choose the cold plate, hot plate, pickling board and other pickling plate, pickling board surface as the pickling too so into normal metal color, but remained in the high cold plate, cold rolled so surface without pickling plate surface oxide layer with, usually hair black, or ferroferric oxide layer, popular is the fire roasted, and if the environment is not good words will often bring some embroidery.

2, performance: in general, hot plate and pipes in the engineering mechanical properties are no more thought, although there are certain work hardening heat pipes in the process of cold rolling, (but do not rule out strict in mechanical properties, that is need to discriminate), cold plate heat plate usually slightly high yield strength, surface hardness is higher, what specific needs to see the degree of cold plate annealing. But no matter how annealing cold plate strength is high specific heat plate.

3, formability, due to the hot and cold plate performance basic difference is not too much, so the influence factors of forming performance depends on the difference between surface quality, due to the better surface quality is studied experimentally to, so generally steel plate with the same material, cold plate heat plate forming effect is better.

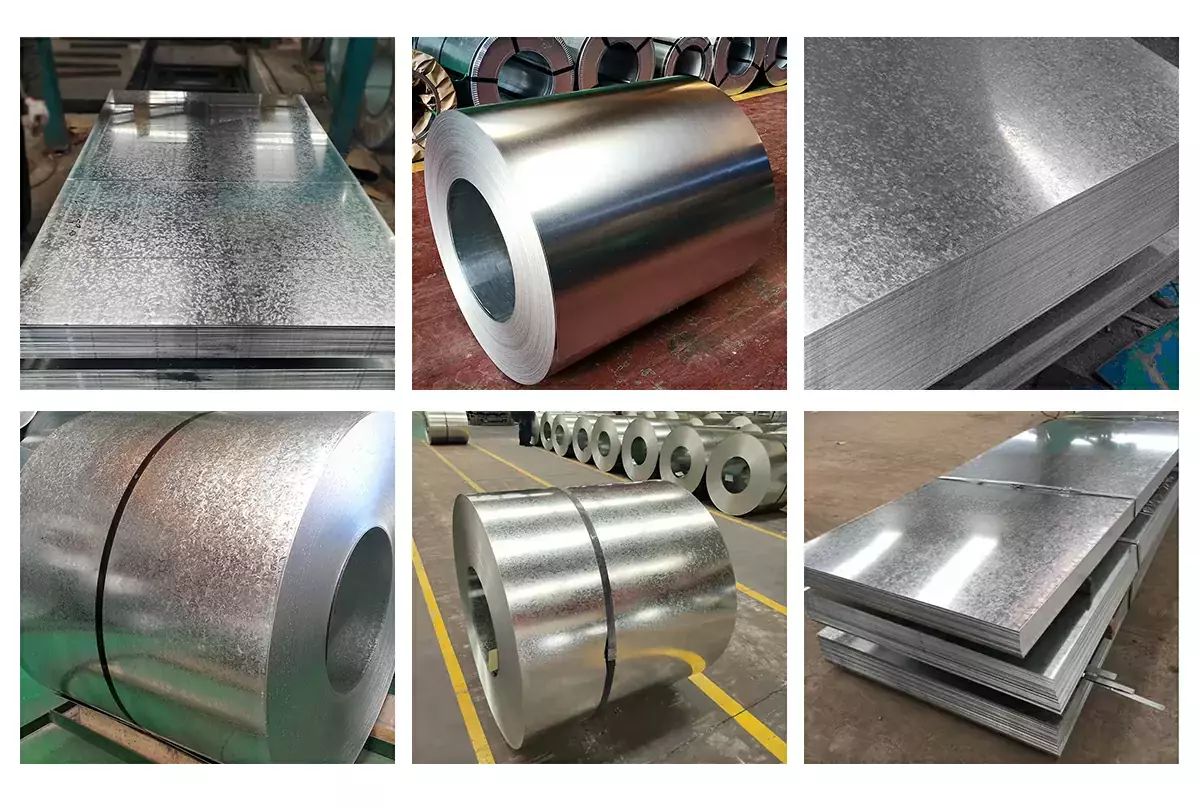

Steel Photos

Steel Packing

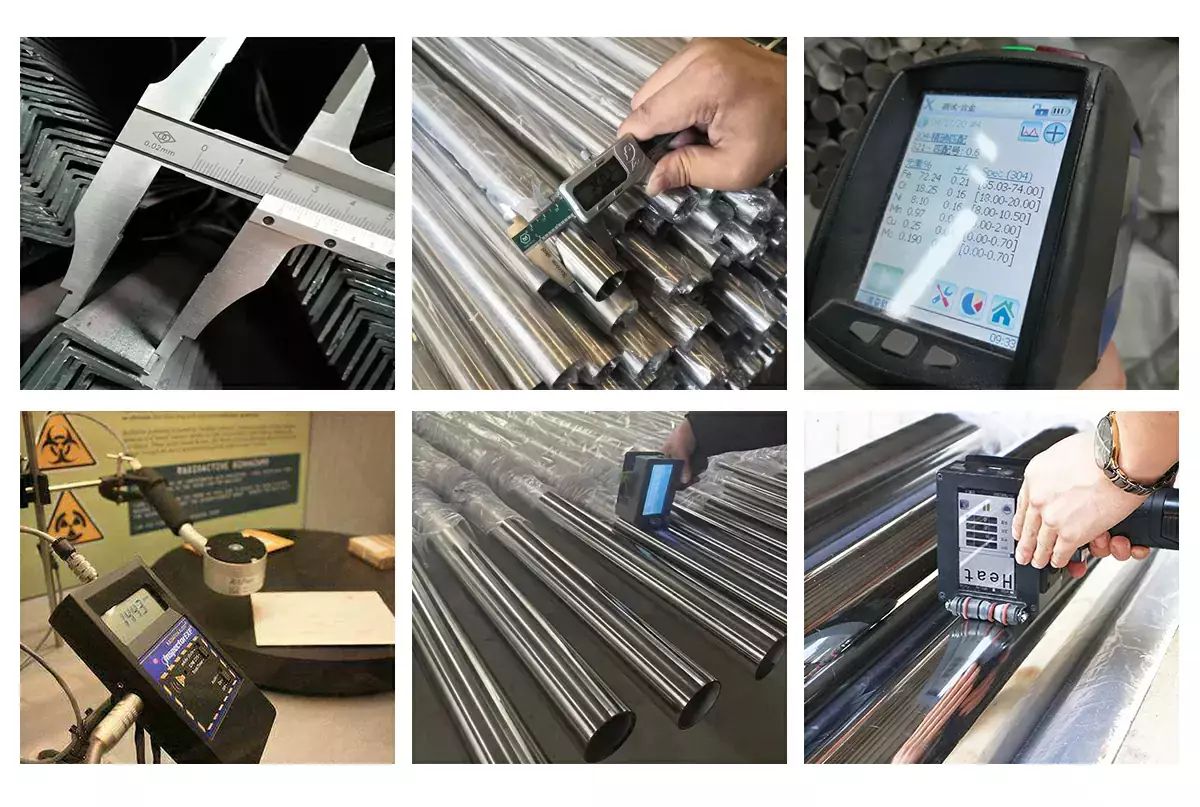

Quality Control

CR380LA Steel FAQS

What is CR380LA steel?

CR380LA steel is a cold-rolled low-alloy high-strength steel. It is a kind of carbon steel with a small amount of alloy elements added to its chemical composition. These alloy elements are mainly used to strengthen the strength of steel.

What does CR380LA steel grade mean?

CR refers to cold rolling, 380 refers to the minimum yield strength of steel of 380MPa, and LA refers to the type of steel of low alloy steel.

Is CR380LA steel the shooting standard?

The executive standard of CR380LA steel is: GB/T 20564.4-2010

What is the chemical composition of CR380LA?

Carbon C:<0.10

Silicon Si: ≤ 0.50

Manganese Mn: ≤ 1.6

Phosphorus P: ≤ 0.025

Sulfur S: ≤ 0.025

Aluminum Al: ≥ 0.015

Pot Ti:<0.15

Nb: ≤ 0.09

What are the mechanical properties of CR380LA?

Yield strength 0.2 (MPa): ≥ 380-480

Tensile strength: (6bMPa): ≥ 440-560

Elongation (65%): ≥ 19

Remarks: (1) The eye pressure strength is Rp0.2. If there is no obvious sleep, use Rp0.2, otherwise use ReL. (2) The sample is P6 in GB/T228, and the direction of the sample is barrel. (3) When the nominal thickness of the product is 0.5mm, the elongation after fracture is allowed to decrease by 4%; When the nominal thickness of the product is 0.5-0.7mm, the elongation after fracture is allowed to decrease by 2%

What is the specification of CR380LA steel?

The thickness is 0.2-4mm, the width is 600-2000mm, and the steel plate length is 1200-6000mm

If you need special size, you can also contact us.

What is the delivery status of CR380LA steel?

Delivery status: CR380LA steel can be delivered in the form of round bar, steel plate, steel bar, steel coil, etc.

What are the material properties of CR380LA steel?

It is through adding a small amount of silver and other alloys to make it form compounds with carbon, ammonia and other elements and precipitate on the ferrite matrix. Therefore, it has high yield strength and yield strength ratio, as well as good cold formability and weldability, and is suitable for making body structural parts.

What are the characteristics of CR380LA steel?

(1) It has good durability, long service life and long service life;

(2) It has good heat resistance and is not easy to change color under high temperature;

(3) Excellent processing performance and spraying performance;

(4) It has good welding performance.

How is CR380LA steel made?

The manufacturing method of CR380LA steel is similar to other types of steel.

Iron ore and coal are combined in the furnace, and then the smelting materials burn off some impurities. Then, according to the grade of HSLA steel, different amounts and types of alloy elements are added to the molten mixture. Once the appropriate chemical composition is obtained, other steps should be taken to ensure that the contaminant content in CR380LA steel reaches the maximum, then the steel is solidified into large rectangular ingots, and finally the CR380LA ingot is processed to the final size.

What are the advantages of CR380LA steel?

Compared with standard carbon steel, CR380LA steel has many advantages. The addition of alloying elements improves the strength and hardness of steel.

The atoms of elements help to prevent dislocation movement in the microstructure of carbon steel. Alloy elements such as tungsten, vanadium, silicon, nickel, molybdenum and manganese will increase the strength and hardness of carbon steel. Nickel can increase the toughness of steel.

The corrosion resistance of CR380LA steel can also be improved. Alloy elements such as copper, nickel and chromium can enhance the corrosion resistance of steel.

This can be achieved because copper, nickel and chromium in CR380LA steel are easier to oxidize than iron. This can prevent iron from forming iron oxide and rust.

What is the grade of CR380LA steel?

Because it can use a variety of alloy elements, HSLA steel also has many different grades.

It can be divided into three types: ordinary quality low alloy steel, high-quality low alloy steel and special quality low alloy steel.

The intended use of HSLA steel mainly depends on the chemical composition and grade application. CR380LA steel is a high grade low alloy high strength steel

What are the typical applications of CR380LA steel?

CR380LA typical application: car interior panel, car seat parts, beam and other structural parts, electrical appliances and household appliances structural parts, etc

What is the development status of CR380LA?

With the development of science and technology, the design of welded structures is becoming more and more high parameter, lightweight and large-scale, which puts forward higher and higher requirements for the performance of steel. Low-alloy steel has been more and more widely used in welded structures due to its excellent performance and remarkable economic benefits.

The development of low alloy steel has gone through three stages. Before the 1920s, riveting was mainly used for the manufacture of steel structures in engineering, and the design parameters were mainly tensile strength. The strengthening of steel mainly depends on carbon and single alloy elements, such as Mn, Si, Cr, etc., with a total mass fraction of 2% – 3%, or even higher. In the 2060s, welding technology was gradually adopted in steel structure manufacturing. The design parameters should consider the yield strength, toughness and weldability requirements of the material. In order to prevent welding cracks, the development direction of low-carbon multi-alloying with chemical composition is rigid. The mass fraction of carbon is generally below 0.2%, containing 2 to 4 alloying elements beneficial to weldability, and laying heat treatment and other process measures. After the 1970s, low alloy high strength steel developed rapidly. The carbon content in steel decreased to less than 0.1%, and some steel developed towards ultra-low carbon content. Ti、V、Nb and other alloy trace elements have gradually attracted attention, and are developing in the direction of multi-element composite alloying. The major progress of modern low alloy steel has entered a new era in the development of low alloy high strength steel worldwide since the 1970s. Based on the metallurgy of controlled rolling technology and microalloying, a new concept of modern low alloy high strength steel, namely microalloyed steel, has been formed. In the 1980s, a variety development involving a wide range of industrial fields and special material categories reached its peak with the help of achievements in metallurgical technology.

Application of low alloy steel, low alloy steel in buildings and bridges. Construction machinery and other industries cannot be widely used. When alloy steel is used in important welded structures such as bridges, offshore buildings and lifting machinery, the impact toughness requirements shall be put forward according to the minimum temperature of the structure. For low alloy structural steel working in atmospheric environment, the impact absorption energy (0C, V-notch impact specimen) shall at least meet the requirements of 27J. For the moving structure of vehicles, ships and construction machinery, reducing the dead weight can save energy and put forward the carrying capacity and industrial efficiency. Therefore, the use of low carbon quenched and tempered steel with good weldability can promote the development of engineering structures in the direction of mass, lightweight and high efficiency. As the wall thickness is reduced and the weight is reduced, the welding workload is reduced, which creates conditions for field construction and hoisting. This kind of steel has good strength, toughness and comprehensive performance, which can greatly improve the durability of the equipment and prolong its service life. WCF-80 steel is a high-strength welded structural steel with low welding crack sensitivity developed after WCF-62 in China. This steel has high cold crack resistance and low temperature toughness, and is mainly used in large hydropower stations, petrochemical and open-pit coal mines. Low-carbon quenched and tempered steel with tensile strength of 700MPa and good notch impact toughness can be used for welded structures serving at low temperatures, such as large excavators and electric wheel dump trucks in open-pit mines. Low-carbon quenched and tempered steel with tensile strength of 800MPa is mainly used in the manufacturing of construction machinery and mining machinery, such as bulldozers, construction cranes, heavy trucks and rotary drills. Low-carbon quenched and tempered steel with tensile strength of more than 10000 MPa is mainly used in high-strength wear-resistant parts of construction machinery, nuclear power plants and navigation and aerospace equipment.