VW 50065 CR420LA

VW 50065 CR420LA steel is a high-strength, low-alloy steel that provides excellent weldability and formability. This steel is designed for use in vehicles and other applications where strength and durability are required. VW 50065 CR420LA steel offers a wide range of benefits, including improved strength, better weldability, and increased resistance to corrosion. As a result, VW 50065 CR420LA steel is an excellent choice for a variety of applications. Solucky Steel is proud to offer VW 50065 CR420LA steel to our customers. This steel is available in a wide range of sizes and thicknesses, making it easy to find the perfect option for your needs. We are confident that you will be satisfied with the quality of our VW 50065 CR420LA steel. Contact us today to learn more about this versatile steel or to place an order.

VW 50065 CR420LA Mechanical properties

| The material | VW 50065 CR420LA | |||||||

| Chemical composition | C% | Si% | Mn% | P% | S% | Ai% | Ti% | Nb% |

| ≤ 0.12 | ≤ 0.50 | ≤ 1.65 | ≤ 0.030 | ≤ 0.025 | ≥ 0.015 | ≤ 0.15 | ≤ 0.09 | |

| Mechanical properties of | YS | TS(MPa) | EL | |||||

| 420-520 | 480-590 | ≥17 | ||||||

VW 50065 CR420LA Processing method

With hot rolled steel coils as raw material, after acid pickling to remove oxide skin for cold rolling, the finished product is hard, because of cold work hardening caused by deformation of continuous cold rolling hard roll strength, increase hardness, toughness and plastic index decreased, so the stamping performance will deteriorate, can only be used for simple deformation of the parts. Hard coil can be used as a raw material, hot dip galvanized factory for hot dip galvanizing unit Settings are annealed wire. Hard coil weight generally in June to 13.5 tons, steel at room temperature, for continuous rolling of hot rolled pickling volumes. Inner diameter is 610 mm.

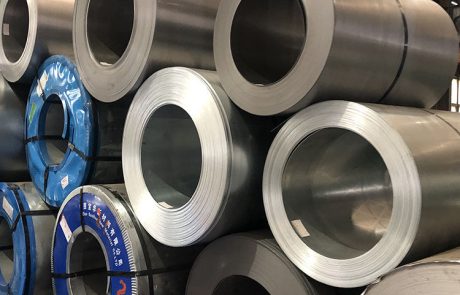

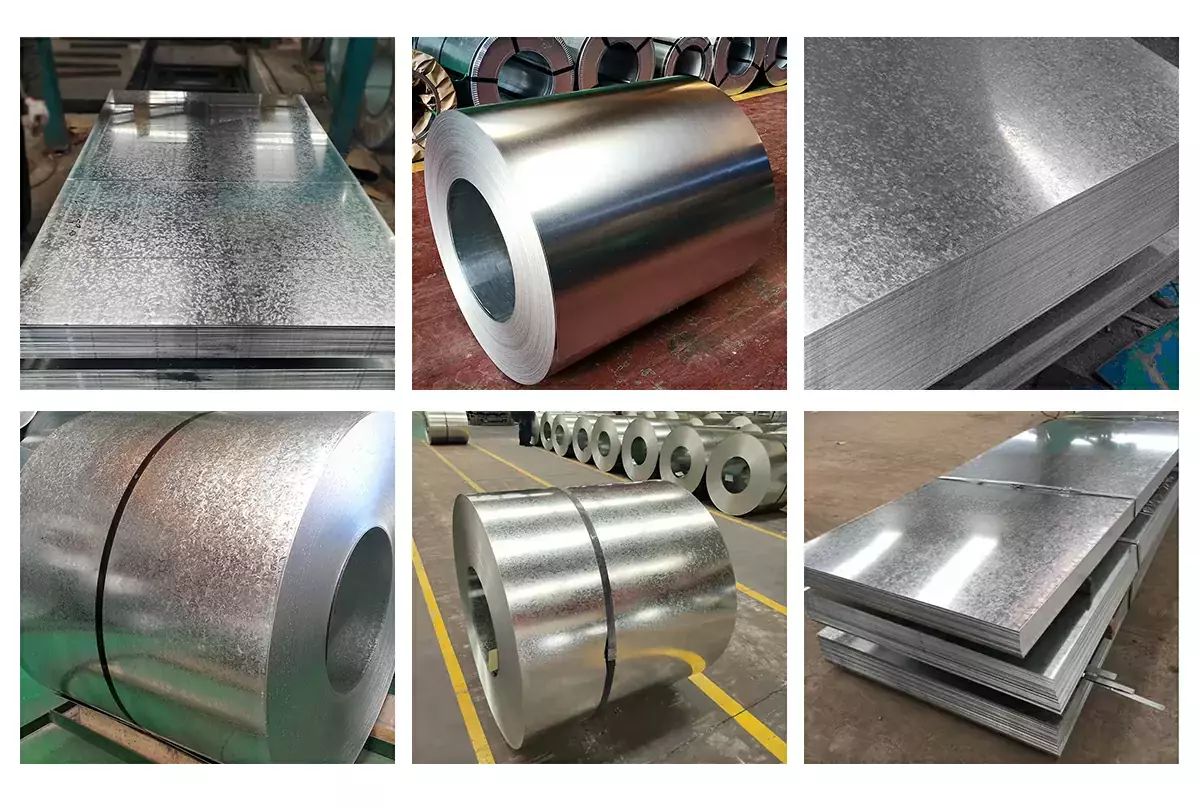

Steel Photos

Steel Packing

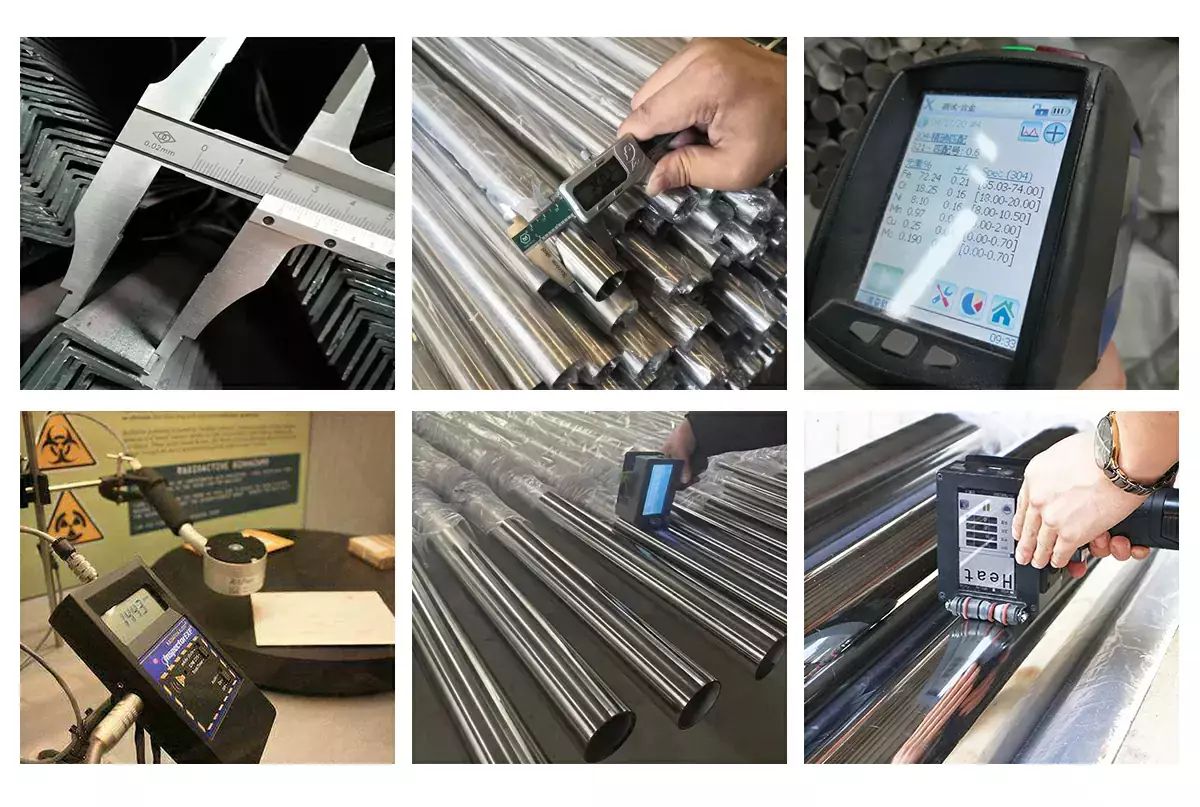

Quality Control

Cr420la Steel FAQ

What is cr420la steel?

Cr420la steel is a high-carbon chromium alloy steel that provides corrosion resistance, hardness, and wear resistance. The alloy has a martensitic structure and is magnetic. Crla steel is used in a variety of applications, including cutting tools, wear-resistant coatings, and springs.

What is the chemical composition of CR420LA steel?

The main chemical composition of CR420LA steel is:

Carbon (C) 0.35 max.

Manganese (Mn) 1.60 max.

Silicon (Si) 0.60 max.

Phosphorus (P) 0.035 max.

Sulphur (S) 0.040 max.

Chromium (Cr) 16 – 18 %

Nickel (Ni) 3 – 5 %

Molybdenum (Mo) 0.5 – 1 %

What are the physical Properties of CR420LA steel?

– CR420LA is a low carbon steel that exhibits good weldability and formability.

– It has a slightly higher carbon content than other low carbon steels, which gives it better strength and hardness properties.

– CR420LA can be heat treated to achieve higher hardness levels, but this will also decrease its ductility and toughness.

Where to find cr420la steel?

Cr420la steel can be found in a variety of places. One place to look is online metal distributors. There are many online metal distributors that sell cr420la steel. Another place to look is your local steel supplier. Many local steel suppliers carry cr420la steel.

How to use cr420la steel?

There are many ways to use cr420la steel. It can be used in construction, automotive, and aerospace applications. Cr420la steel is a versatile material that can be heat treated to improve its properties.

What are the advantages of CR420LA steel?

CR420LA steel is a high-strength, low-alloy steel that can be welded and heat treated to produce a variety of products, including shafts, axles, pipes, and other parts for machinery and equipment. This type of steel is easy to work with and can be cold or hot formed to create the desired shape. CR420LA steel offers good weldability, machinability, and toughness properties. It also has excellent corrosion resistance and can be used in a variety of environments.

What are the disadvantages of CR420LA steel?

There are a few potential disadvantages to using CR420LA steel. First, this type of steel is susceptible to corrosion. This means that it may not be ideal for use in environments where there is a lot of moisture or exposure to chemicals. Additionally, CR420LA steel may not be as strong or durable as some other types of steel.

What is the process of heat treating CR420LA?

Heat treating is a process of heating and cooling metals to change their physical and mechanical properties. The most common reason for heat treating carbon steel is to harden it. The process of hardening steel involves heating the steel to a specific temperature, then cooling it rapidly. This process creates a harder, more durable metal.

What are the pros and cons of heat treating CR420LA?

Heat treating CR420LA is a process that can have both positive and negative consequences. The main pro of heat treating this type of steel is that it increases its hardness, making it more durable and less likely to break under stress. However, the con of heat treating CR420LA is that it can also make the steel more brittle, which can lead to cracking or shattering if not handled properly.

How to choose the best heat treatment for CR420LA?

There are a few things to consider when choosing the best heat treatment for CR420LA. The first is the desired hardness. CR420LA can be heat treated to a variety of different hardness levels, so it is important to know what level of hardness is desired before choosing a heat treatment. The second thing to consider is the application the metal will be used in. Some applications require higher levels of hardness than others, so it is important to make sure that the heat treatment you choose can achieve the level of hardness required for your application. Finally, it is important to choose the right CR420LA heat treatment for your application. There are three main types of heat treatments: annealing, normalizing, and hardening. Each has its own benefits and drawbacks, so be sure to choose the one that best suits your needs.

Can CR420LA steel be welded?

Yes, CR420LA steel can be welded using any standard welding method. However, care must be taken to avoid overheating the steel during welding, as this can cause the formation of detrimental metallurgical structures.

How to weld CR420LA steel?

While CR420LA steel can be welded, it is important to note that this particular type of steel is known for being difficult to weld. This is due to its high carbon content, which can make the steel hard and brittle. As a result, welding CR420LA steel can be challenging and requires both skill and experience.

Here are some tips on how to weld CR420LA steel:

– Use a low current setting when welding. This will help to prevent the steel from overheating and becoming too brittle.

– Use a short arc when welding. This will also help to prevent the steel from overheating.

– Keep your welds small. Overheating the steel can cause it to crack, so it is important to keep your welds small in order to avoid this issue.