VW 50065 HR300LA

VW 50065 HR300LA is a high strength, low alloy steel that is specifically designed for welding applications. It provides excellent weldability and toughness, making it an ideal choice for VW 50065 HR300LA applications. VW 50065 HR300LA has been widely used in the automotive, construction and manufacturing industries due to its superior weldability and toughness. VW 50065 HR300LA is available from Solucky Steel in a variety of sizes and shapes to suit your specific application needs. Contact Solucky Steel today to learn more about VW 50065 HR300LA and how it can benefit your business.

VW 50065 HR300LA Chemical composition

| The material | VW 50065 HR300LA | |||||||

| Chemical composition | C% | Si% | Mn% | P% | S% | Ai% | Ti% | Nb% |

| ≤ 0.12 | ≤ 0.50 | ≤ 1.30 | ≤ 0.030 | ≤ 0.025 | ≥ 0.015 | ≤ 0.15 | ≤ 0.10 | |

| Mechanical properties of | YS | TS(MPa) | EL | |||||

| 300-380 | 380-500 | ≥24 | ||||||

VW 50065 HR300LA Role

Hot rolled steel is a high temperature heating of rolling steel, its strength is not high, but enough to meet our use, its plasticity, good weldability so we compare common; Cold rolling is ordinary hot-rolled steel after strong drawing more than stage of strain hardening steel, its strength is very high, but the toughness and weldability poor, hard and brittle. Hot rolling is processed at high temperatures. More than 1000 degrees, etc., make steel internal recrystallization. Make it the material better. But hot rolling will not change the metal structure performance.

The characteristics of VW 50065 HR300LA

hot-rolled products have high strength, good toughness, easy to processing molding and good weldability and other excellent properties, and therefore is widely used in ship, automobile, Bridges, buildings, machinery, pressure vessels and other manufacturing industries

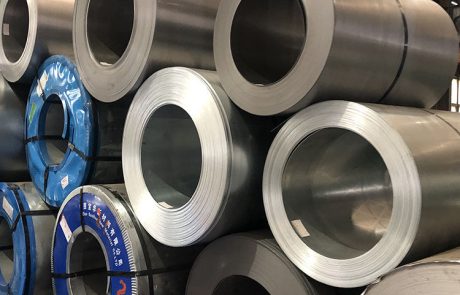

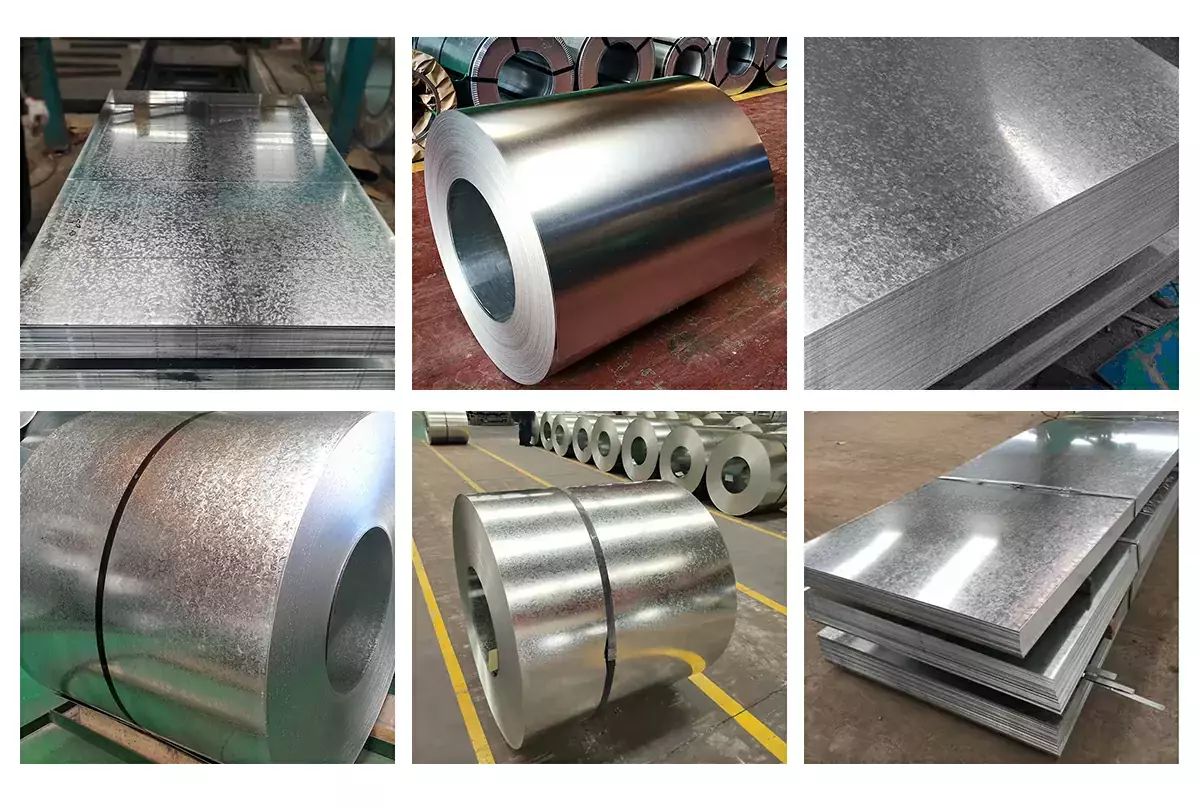

Steel Photos

Steel Packing

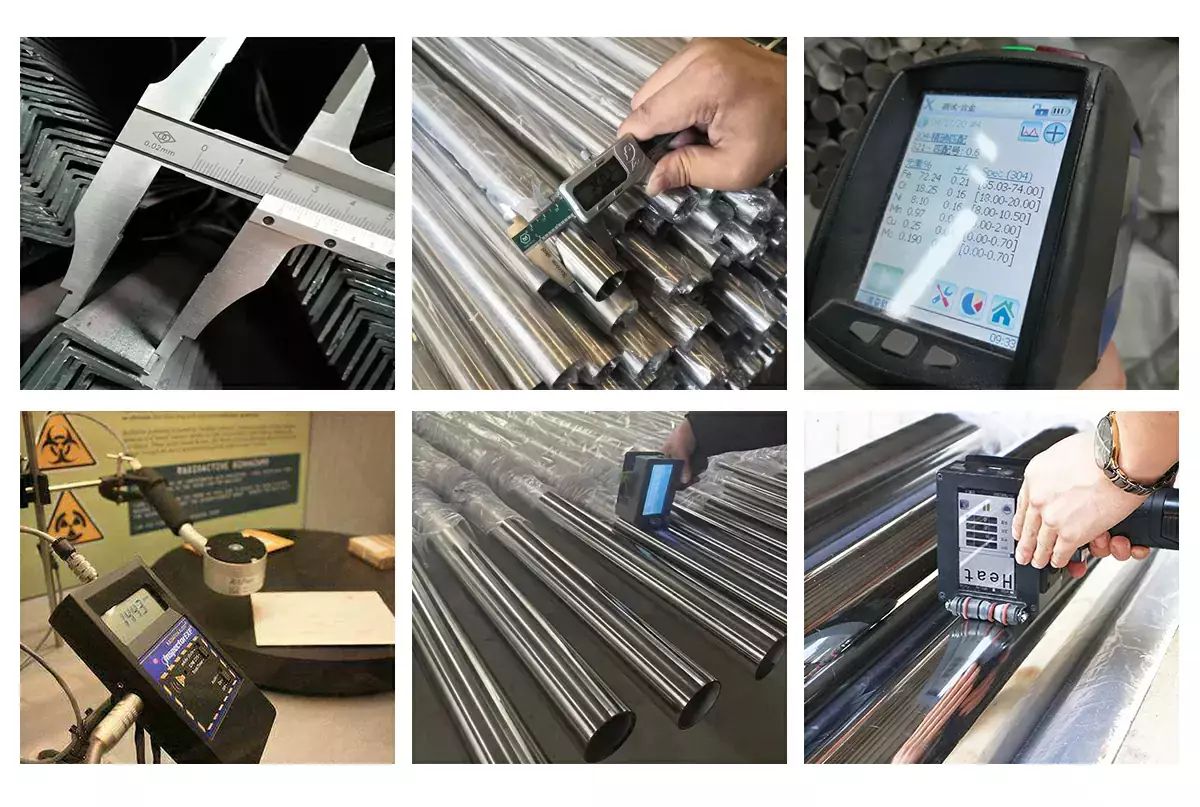

Quality Control

FAQ About Hr300la

What is Hr300la steel?

HR300LA steel is a high-strength low-alloy steel with improved weldability and formability. The material is used in a variety of applications, including automotive, construction, and manufacturing. HR300LA steel is available in a variety of grades, each with different mechanical properties.

What are the benefits of Hr300la steel?

Hr300la steel is a high-strength, low-alloy steel that offers an array of benefits over traditional carbon steel. Hr300la steel is more resistant to corrosion and abrasion, making it an ideal choice for applications that are exposed to harsh environments. Additionally, hr300la steel has a higher yield strength than carbon steel, making it ideal for load-bearing applications.

What are the drawbacks of Hr300la steel?

There are several drawbacks to Hrla steel. First, it is an expensive material. Second, it is difficult to weld and fabricate. Third, it has a high carbon content, which can make it susceptible to cracking. Finally, it is not as strong as other steels, such as titanium or stainless steel.These properties make them unsuitable for many applications.

What is the chemical composition of Hr300la steel?

Hr300la steel is an alloy of iron and carbon, containing between 0.3% and 1.2% carbon by weight. The chemical composition of Hr300la steel varies depending on the manufacturer, but it typically contains between 0.7% and 1.0% manganese, 0.4% to 0.7% silicon, and trace amounts of other elements such as phosphorus, sulfur, chromium, and molybdenum.

What are the characteristics of Hr300la steel?

Hr300la steel is a high strength, low alloy steel that has been processed to achieve specific mechanical and chemical properties. This steel exhibits excellent weldability, formability and toughness. It is commonly used in automotive and aerospace applications.

What are the raw materials of Hr300la steel?

Hr300la steel is an alloy of iron and carbon, containing between 0.3% and 1.2% carbon by weight. The raw materials for Hr300la steel are iron ore, coal, and limestone. The iron ore is smelted in blast furnaces to produce pig iron, which is then converted to wrought iron or steel in a variety of processes. The coal is used as a fuel source in the blast furnace and the limestone is used as a flux to remove impurities from the pig iron.

How to use Hr300la steel?

If you’re looking for an extremely versatile and durable steel, Hr300la is a great option. It can be used for a variety of applications, including construction, automotive, and even medical purposes. Here’s a quick guide on how to use Hr300la steel:

First, you’ll need to determine what thickness you need. Hr300la is available in both sheet and plate form, so it’s important to know which one you need for your project. Sheet metal is thinner than plate metal, so it’s typically used for smaller projects. Plate metal is thicker and more durable, making it ideal for larger projects or applications that require more strength.

Once you know what thickness you need, you can begin cutting the steel to size. Hrla can be cut with traditional power tools like saws and shears. However, if you’re working with very thin sheets of steel, it’s important to use caution to avoid damaging the material.

Once you have the pieces cut to size, you can begin welding them together. Hr300la welds easily with standard arc welding equipment. Just be sure to use the proper welding rod and shield gas for the job; otherwise, you could damage the steel.

After welding, you’ll want to finish the surface of the steel to protect it from corrosion. There are a variety of ways to do this, but one popular method is powder coating.

What is the difference between Hr300la steel and other steels?

Hr300la steel is a newer type of steel that has been developed for use in construction. This steel offers high strength and durability, while also being lightweight and easy to work with. Hr300la steel has been shown to outperform other steels in many ways, making it an excellent choice for use in a variety of applications.

How is Hr300la heat treated?

Hr300la heat treatment is a process that alters the physical and chemical properties of steel to improve its strength and hardness. There are several methods of heat treatment, but the most common is through-hardening. This process involves heating the steel to a high temperature and then cooling it rapidly. The rapid cooling creates a harder and stronger steel.

What are the benefits of Hr300la heat treated?

There are many benefits to heat treating Hr300la steel. The most notable benefits include:

1. Increased hardness and strength – Heat treating Hr300la steel increases its hardness and strength, making it more durable and resistant to wear and tear.

2. Improved resistance to corrosion – Heat treating Hr300la steel also improves its resistance to corrosion, making it an ideal choice for applications where corrosion resistance is important.

3. Enhanced weldability – Heat treating Hr300la steel makes it easier to weld, which can be an important consideration in applications where welding is required.

4. Improved machinability –Heat treating Hr300la steel also improves its machinability, making it easier to work with during the manufacturing process.

What are the applications of Hr300la steel?

Hr300la steel is one of the most versatile and hard-working materials available on the market today. Its applications are wide-ranging, from construction and automotive to aerospace and military. Hr300la steel is known for its strength, durability, and resistance to wear and tear. It is also easy to weld and can be machined to a variety of shapes and sizes.

What is the process of making Hr300la steel?

The process of making Hr300la steel is a complicated one that involves many steps. First, the raw materials must be gathered. These include iron ore, coal, and limestone. Next, the iron ore is smelted in a blast furnace to create molten iron. This molten iron is then combined with scrap steel and other alloys to create the desired Hr500la steel composition. Finally, the steel is cast into ingots or slabs and cooled to create the finished product.