VW 50065 HR340LA

VW 50065 HR340LA is a high strength low alloy steel that is commonly used in the automotive industry. This type of steel provides excellent weldability and formability, making it ideal for use in body panels and other car components. Solucky Steel is proud to offer VW 50065 HR340LA steel in a variety of grades and sizes to meet the needs of our customers. This versatile steel can be used for a wide range of applications, and we are confident that we can provide the perfect solution for your project. Contact us today to learn more about our VW 50065 HR340LA steel products.

VW 50065 HR340LA Chemical composition and Mechanical properties (Mpa):

| The material | VW 50065 HR340LA | |||||||

| Chemical composition | C% | Si% | Mn% | P% | S% | Ai% | Ti% | Nb% |

| ≤ 0.12 | ≤ 0.50 | ≤ 1.50 | ≤ 0.030 | ≤ 0.025 | ≥ 0.015 | ≤ 0.15 | ≤ 0.10 | |

| Mechanical properties of | YS | TS(MPa) | EL | |||||

| 340-440 | 420-540 | ≥22 | ||||||

The characteristics of:

hot-rolled products have high strength, good toughness, easy to processing molding and good weldability and other excellent properties, and therefore is widely used in ship, automobile, Bridges, buildings, machinery, pressure vessels and other manufacturing industries

VW 50065 HR340LA conclusion

With the development of society and economy, iron and steel enterprises to obtain the unprecedented opportunity. Used in iron and steel industry development in the process of hot rolled steel with continuous hot galvanizing production technology improve steel quality has become the inevitable choice of iron and steel enterprises

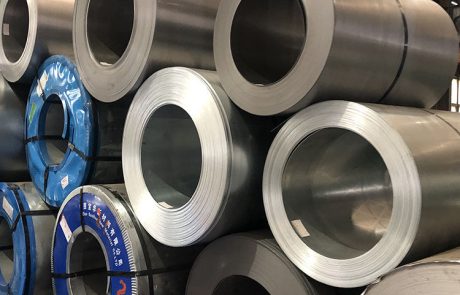

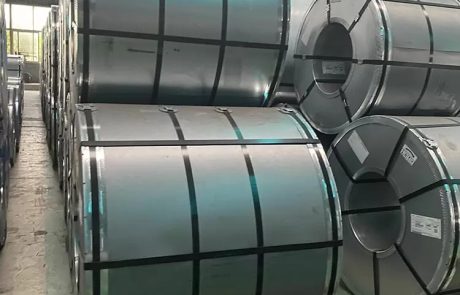

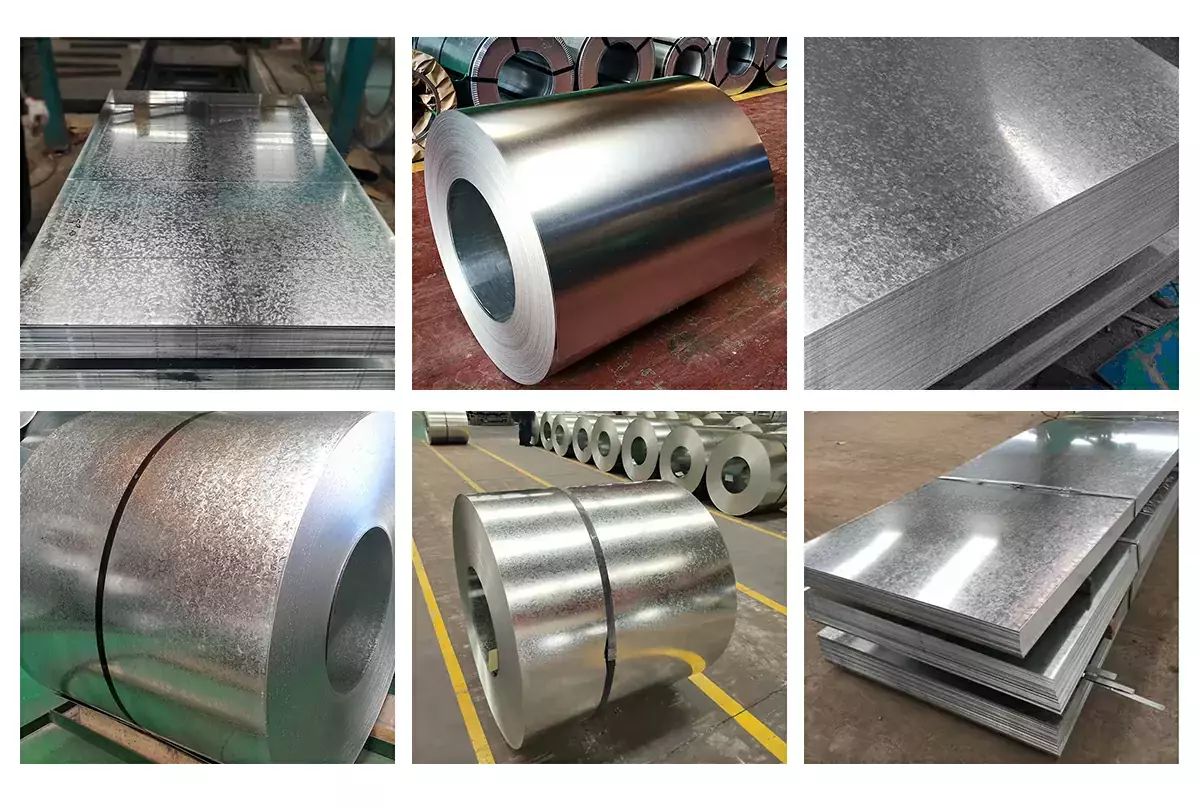

Steel Photos

Steel Packing

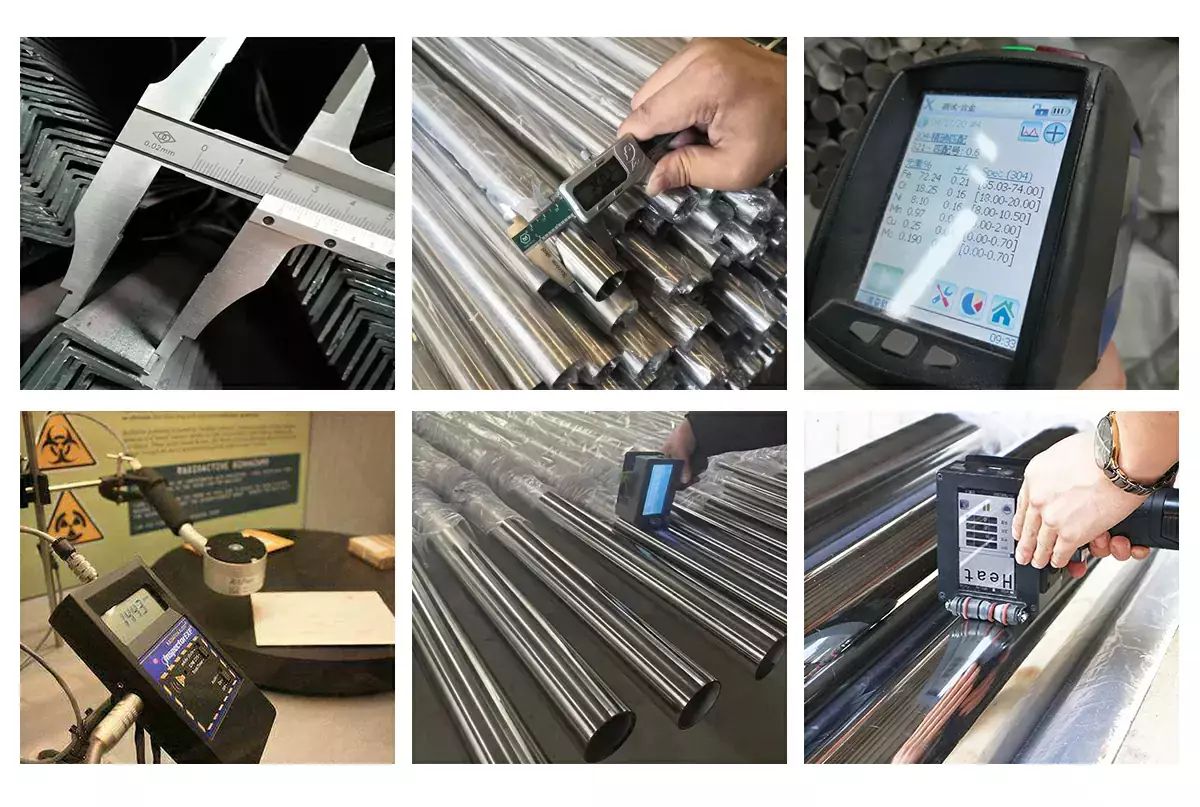

Quality Control

FAQ About Hr340la steel

What is Hr420la steel?

Hr340la steel is a high-strength, low-alloy steel with excellent corrosion resistance and good weldability.It is a type of low carbon steel that has been heavily alloyed with manganese. This makes it extremely strong and hard wearing, making it ideal for applications where high levels of wear and tear are expected. Hr340la steel is often used in construction, agricultural and earthmoving equipment, as well as in many other heavy duty applications.

What is the chemical composition of Hr340la steel?

The chemical composition of Hr340la is:

Element Content (%)

Carbon (C) 0.04-0.08

Manganese (Mn) 1.00-1.30

Sulfur (S) 0.035max

Phosphorus (P) 0.035max

Silicon (Si) 0.40-0.70

Chromium (Cr) 13.00-15.00

Nickel (Ni) 3.50-5.50

What are the properties of Hr340la Steel?

Hrla steels are low-carbon, high-strength steels that exhibit excellent weldability and formability. These properties enable hrla steels to be used in a variety of applications, including automotive, construction, and manufacturing.

What are the benefits of Hr420la steel?

Hr340la steel is a kind of steel with highstrength, good toughness and excellent weldability. It is widely used in many industries such as construction, machinery manufacturing, shipbuilding, bridges, pressure vessels and so on. Hr340la steel has many advantages:

- High strength: The yield strength of hr340la steel is more than twice of that of common carbon structural steels, which can reduce the weight of structures and save a lot of materials.

- Good toughness: Hr340la steel has good toughness and not easy to crack. It can work in harsh environments.

- Excellent weldability: Hr340la steel has excellent weldability and can be welded by all welding methods.

- Good machinability: Hr340la steel has good machinability and can be processed into various shapes and sizes according to engineering requirements.

What are the drawbacks of Hr340la steel?

There are a few drawbacks to Hr340la steel. One is that it is not as strong as other types of steel. This means that it is more likely to bend or break under pressure. Another drawback is that it is not as easy to weld as other types of steel. This can make it difficult to repair if it breaks.

How to Weld Hr340la Steel?

Welding Hr340la steel is a process that uses high-frequency electrical current to heat and join two pieces of metal. The most common metals used in welding are carbon steel, stainless steel, aluminum, and copper.

The first step in welding Hr420la steel is to clean the metal surfaces that will be joined together. Any dirt, grease, or other contaminants on the surface can prevent the weld from bonding properly. Next, the welder sets up the equipment needed for the specific type of weld being performed.

The third step is to actually make the weld. This is done by passing an electric current through the electrode and into the metals being joined. The heat from the current melts the metals, which fuse together as they cool. Finally, any excess weld material is removed and the joint is inspected for defects.

How to heat treat Hr340la steel?

Hr340la steel is a low-alloy steel that contains chromium and molybdenum as strengthening agents. The additions of these elements give the steel increased hardness and wear resistance. Hr340la steel is usually heat treated using one of two methods: quenching and tempering or annealing.

Quenching and tempering involves heating the steel to above its critical temperature, then cooling it rapidly in water or oil. This process hardens the steel by transforming its microstructure. Tempering further strengthens the steel by reheating it to a lower temperature and then allowing it to cool slowly.

Annealing is a heat treatment process that softens the steel by heating it below its critical temperature and then cooling it slowly. This allows the atoms in the steel to rearrange themselves into a more stable configuration, which makes the steel more ductile and less brittle.

What are the benefits of heat treating Hr340la steel?

Hr340la steel is heat treated in order to improve its hardness, strength, and wear resistance. The process of heat treating Hr420la steel involves heating the metal to a specific temperature and then cooling it rapidly. This helps to preserve the desirable properties of the steel while making it more durable. Heat treating Hr420la steel can also improve its weldability.

What is the heat Treatment of Hr340la Steel?

The heat treatment of Hr340la steel is a process that changes the microstructure of the steel to achieve specific mechanical or metallurgical properties. The most common heat treatment processes include annealing, quenching, and tempering. Steel is heated to a specific temperature and then cooled at a specified rate to harden or soften the material.

How to use Hr340la steel?

Hr340la steel is a versatile material that can be used for a variety of applications. Here are some tips on how to use this material:

-Hr340la steel can be used in the construction of buildings and bridges.

-This material can also be used in the manufacturing of cars and other vehicles.

-Hr340la steel can also be used in the production of pipes and other piping materials.

How to choose the right steel for your project?

There are a few things to consider when choosing the right steel for your project. The first is the strength of the steel. HR340LA steel is very strong, so it is often used in construction projects. However, it can also be brittle, so it is important to choose a steel that will be strong enough for your project.

The second thing to consider is the corrosion resistance of the steel. HR340LA steel is resists corrosion well, so it is often used in outdoor applications. However, it can still corrode over time, so it is important to choose a steel that will resist corrosion for the lifetime of your project.

The third thing to consider is the weldability of the steel. HR340LA steel welds well, so it is often used in welding projects. However, there can be problems with welding this type of steel, so it is important to choose a steel that will weld well for your project.

fourthly you should take into account formability which means how easily the metal can be formed into specific shapes without breaking and finally hardness which indicates how resistant the metal will be to scratching and wear over time.