Quenched ductile steel – HR600/980QP

What is quenched ductile steel?

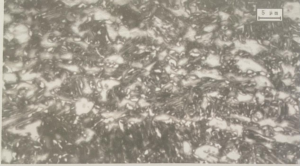

Based on martensite, it also contains a certain amount of ferrite and about 8%-12% retained austenite. Utilize the transformation-induced plasticity effect of retained austenite during deformation to obtain higher work hardening performance and elongation level. Compared with high-strength steel of the same strength level, quenched ductile steel has better plasticity and formability.

Typical QP steel metallographic structure

Is HR600/980QP a quenched ductile steel?

HR600/980QP is a typical quenched ductile steel specially designed for automotive structural applications. It is usually produced by a cold rolling process and has a yield strength of 600 MPa (megapascals) and a tensile strength of 980 MPa.

The “HR” in HR600/980QP stands for “Cold Rolled”, which means that the steel is processed at low temperature to increase its strength and durability. “600” refers to the steel’s yield strength, the amount of stress a material can withstand before it begins to deform plastically. “980” refers to the tensile strength of steel, which is the maximum stress a material can withstand before breaking.

The “QP” in HR600/980QP stands for “quenched and tempered”, which means that the steel is heated to a high temperature, then quenched (quenched) and then tempered to improve its mechanical properties. The steel produced by this process has excellent strength, toughness and formability, making it ideal for automotive parts that require high strength and low weight.

What is the chemical composition of HR600/980QP steel?

HR600/980QP steel is a high strength low alloy (HSLA) steel commonly used in structural applications in the automotive industry. The chemical composition of HR600/980QP steel usually includes:

Carbon (C): 0.12% – 0.22%

Silicon (Si): 0.50% max

Manganese (Mn): 1.00% – 2.00%

Phosphorus (P): 0.030% max

Sulfur (S): 0.015% max

Chromium (HR): 0.50% – 0.80%

Molybdenum (Mo): 0.10% max

Nickel (Ni): 0.50% max

Copper (Cu): 0.25% max

Aluminum (Al): 0.015% – 0.060%

Titanium (Ti): 0.10% max

Vanadium (V): 0.15% max

Note that exact composition may vary by specific grade and manufacturer of steel.

What are the mechanical properties of HR600/980QP?

The mechanical properties of HR600/980QP steel are important to determine its suitability for different applications. The following are some typical mechanical properties of this steel:

Yield Strength (min): 600 MPa (87,022 psi)

Tensile Strength (Min): 980 MPa (142,156 psi)

Elongation (min): 14%

Area reduction (minimum): 40%

Hardness (Vickers HV, typical): 280-350

These properties are achieved through a combination of the steel’s chemical composition, processing and heat treatment. High yield and tensile strengths make HR600/980QP steel suitable for structural applications in the automotive industry where strength and weight reduction are important. High elongation and reduction of area also indicate good formability, which is important for stamping and forming operations in the manufacturing process.

What is the process principle of HR600/980QP steel?

The process principle of HR600/980QPQP steel is to heat the steel to the austenitization zone (or two-phase zone) and hold it for a period of time, then rapidly cool it to Ms (martensitic transformation start temperature) and Mf (martensitic transformation End temperature) between the quenching temperature QT and keep it warm to produce an appropriate amount of martensite, then raise the temperature to the partition temperature PT higher than the Ms temperature and keep the temperature for a period of time to ensure the completion of the carbon-rich process of the retained austenite.

What is the room temperature structure of HR600/980QP steel?

The room temperature structure of HR600/980QP steel is mainly carbon-poor lath martensite and carbon-rich retained austenite.

The martensite structure only guarantees the strength of the steel. The retained austenite improves the plasticity of the steel due to the phase transformation induced plasticity during the deformation process. The maximum strength of the steel can reach 1500MPa, while the corresponding elongation is still 15%.

How is HR600/980QP steel heat treated?

The key to the production of HR600/980QP steel is heat treatment temperature control, including: annealing heating rate, annealing temperature Q and time, slow cooling section cooling rate and temperature, quenching cooling rate and temperature, distribution temperature and distribution time.

In the production of HR600/980QP steel, a higher heating rate, two-phase zone annealing, and a lower slow cooling rate and temperature are used to facilitate the introduction of ferrite, stabilize austenite, and increase elongation; The cooling rate is fast, the martensitic structure is obtained, and the high-strength steel is guaranteed.

What are the uses of HR600/980QP steel in automobiles?

Some uses of HR600/980QP steel in automobiles include:

Body structure: The high strength and good formability of HR600/980QP steel make it suitable for automobile body structure. It can be used in components such as A-pillars, B-pillars, roof rails and rocker panels, contributing to the overall strength and crashworthiness of the vehicle.

Chassis and suspension: HR600/980QP steel can also be used for the chassis and suspension of the car. It can be used to manufacture components such as control arms, suspension linkages and subframes to increase the overall stiffness and durability of the suspension system.

Safety parts: HR600/980QP steel has high strength and good formability, and is suitable for safety parts such as door beams, beams, and bumper reinforcements. These components help absorb and distribute energy during a crash, helping to protect the occupants of the vehicle.

Engine and transmission system: In some cases, HR600/980QP steel can also be used in the engine and transmission system of automobiles. It can be used to manufacture transmission gears, crankshafts, camshafts and other components to improve the overall strength and durability of the engine and transmission system.

Overall, the high strength and good formability of HR600/980QP steel make it a versatile material for various automotive applications, helping to improve vehicle safety, durability and overall performance.

What are the supply standards for quenched ductile steel?

Baosteel can supply according to the requirements of international common standards such as European standard, American standard or JIS, or according to the standards or requirements of users, or adopt the following Baosteel standards for supply.

| Steel Grade | YS a b

Rpo2. MPa |

TS

Rm, MPa≧ |

EL≧ |

| HC600/980QP(E+Z) | 600~850 | 980 | 15 |

| HC600/980QP-EL(E+Z) | 600-850 | 980 | 20 |

| HC820/1180QP(E+Z) | 820~1100 | 1180 | 8 |

| HC820/1180QP-EL(E+Z) | 820~1100 | 1180 | 14 |

| HC1100/1470QP | 1100~1400 | 1470 | 13 |

- A.If the yield point is not pronounced, the values of Rp0.2 applyOtherwise, the values of Rel apply.

B.Guaranteed for No.5 tensile specimens according to standardJIS 22241 with the tensile axis vertical to the rolling direction.Note: Please confirm the specifcations of product before officialorder. The specifications are negotiable.

What are the application cases of HR600/980QP steel?

At present, Baosteel QP steel has developed a relatively complete product series with different performance characteristics such as non-coating, hot-dip galvanizing, and zinc alloying; 980MPa, 1180MPa and other strength levels; It can meet the individual needs of different users: the following figure shows several application cases of HR600/980QP steel in automobile manufacturing:

(a) B-pillar reinforcement (left part/right part), material 980 QP; thickness: 2.0mm;

(b) B-pillar inner part, material 980QP; thickness: 1.2mm;

(c) Front floor side member, material 980 QP; thickness: 1.8mm;

(d) Inner door panel (left piece/right piece), material 980 QP; thickness: 1.0 mm.

SOLUCKY Iron and Steel Trading Co., Ltd., as the designated dealer of Baosteel, the designated agreement user of Maanshan Iron and Steel, Shougang, and VAMA, pays more attention to product quality. The company strictly uses high-quality materials, meticulous workmanship, mature technology, and product quality is checked by technical personnel at every level. If you are looking for a suitable quenched ductile steel or have any questions about steel, you can contact us for consultation and look forward to your call!